What Is A Passive RFID Tag?

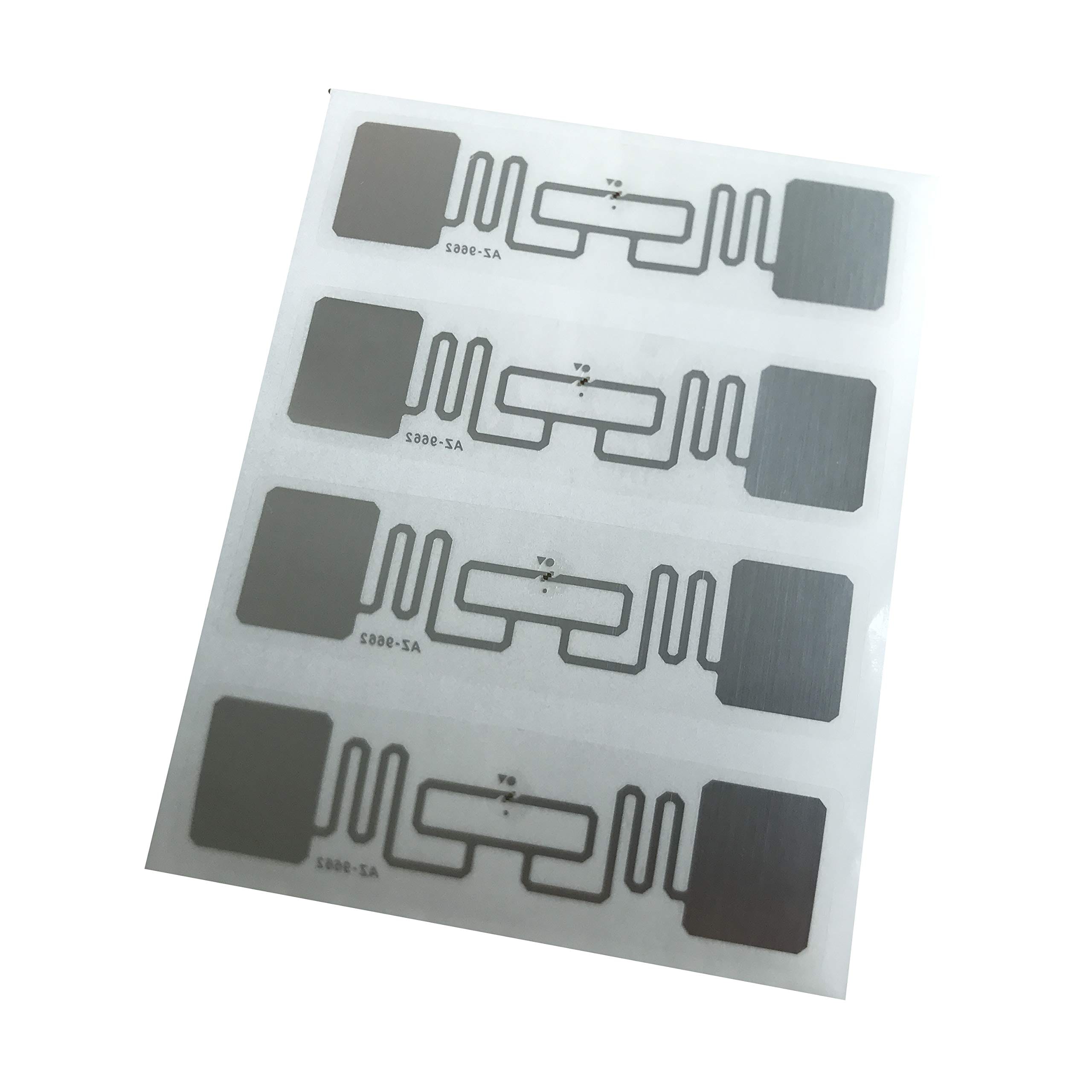

Since no battery is needed, the lowest RFID tag cost comes from a passive RFID tag that will last roughly 20 years. Usually covering 3-5 meters in range, a passive tag’s read range is enough to cover a normal door, dock door or shop floor environment.

Usually used synonymously with EPC Gen2 tags is the term passive RFID tag. Passive RFID systems use the generally accepted EPC Gen2 standard. Here’s a great paper for you to review if you would want further, much more specific understanding of RFID’s operation.

Passive RFID Tags: When to Use Them?

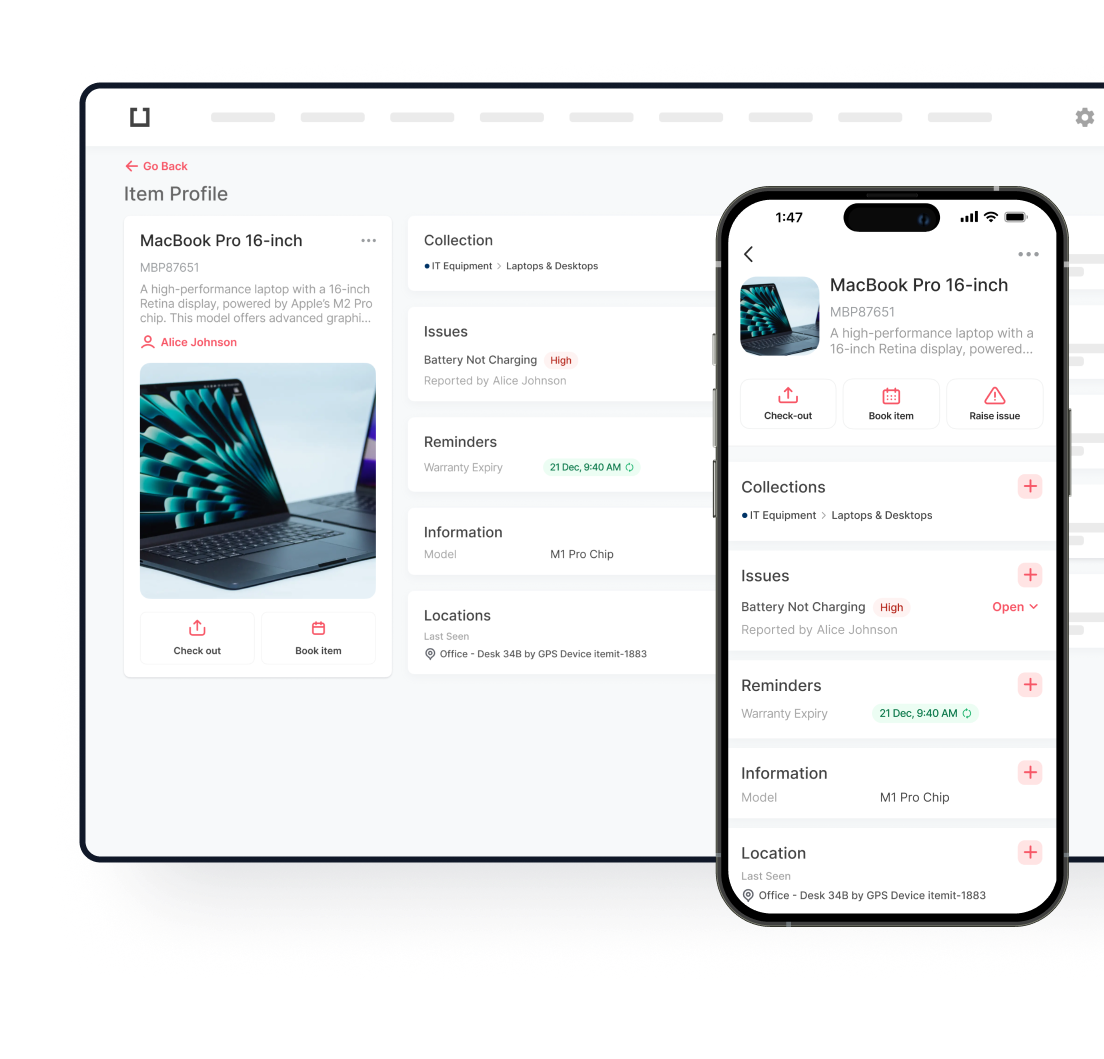

RFID passive vs. active systems provide flexibility if you are looking for a dependable method to track inventory or monitor goods as they pass through supply chains. Passive RFID tags are particularly useful in inventory control, supply chain management, and RFID asset tracking systems where frequent item status updates are not required. They are ideal for rapidly and effectively tracking huge numbers of products since they allow one to scan several tags at once. If you want to know more, you can read about RFID asset tracking explained.

Passive RFID Tags Benefits

- Cost-Effective: Passive RFID tags cost far less than active ones. This makes them perfect for uses requiring hundreds or thousands of tags, such as retail inventory control. One can cut running expenses without compromising effectiveness.

- Small and Lightweight: Smaller and lighter than active tags, passive tags do not need an onboard power source. This lets them be fastened to a great range of objects, from little gadgets to clothes, without adding weight.

- Long Lifespan: Under normal circumstances, passive RFID tags can run practically indefinitely without a battery. A major benefit of long-term projects or when used in environments where tag access is restricted is that you won’t have to be concerned about maintenance or battery replacement.

- Wide Range of Applications: Retail, transportation, and manufacturing are just a few of the sectors where passive RFID tags find application. Passive tags provide flexibility and adaptation for tracking goods in warehouses or through a supply chain.

Passive RFID Tags Disadvantages

- Shorter Read Range: Passive RFID tags’ shorter read range is one of their primary drawbacks. Usually, one can only read them from a few metres’ distances. This makes them less suitable for uses requiring long-range monitoring or tracking.

- Signal Interference: Passive RFID tags may find performance hampered by interference from metal objects, liquids, and other materials. These environmental elements restrict their usefulness in some contexts, such as tracking liquid containers or metal products.

- Limited Data Storage: The limited memory capacity of passive RFID tags limits the amount of data the tag can store directly. In situations where thorough information must be connected to the tracked asset, this could be a drawback.

Active RFID Tags: When to Use Them?

How to use RFID? Active RFID systems are typically used in industries where assets must be tracked over vast distances—such as building sites, hospitals, or shipping yards. This is so because, compared to RFID passive vs. active alternates, they offer more solid tracking solutions.

Active RFID Tags Benefits

- Extended Read Range: The ability of active RFID tags to be read from distances of up to hundreds of metres is one of their main benefits This makes them perfect for monitoring high-value goods en route across great distances or tracking assets in big open areas.

- Real-Time Tracking: Because they have their own power source, active RFID tags can constantly broadcast signals. Real-time asset tracking made possible by this capacity is essential for fleet management, logistics, and environments needing daily updates on asset locations.

- Greater Data Storage: Usually speaking, active RFID tags have more memory than passive ones. This allows them to retain more thorough knowledge about the asset they are linked to, which can be especially helpful for high-value items needing more sophisticated data tracking.

- Suitable for Harsh Environments: Active RFID tags are made to function in demanding conditions. Active tags keep good performance whether tracking assets in high-humidity environments or metal containers, whereas passive tags may fail from interference.

Active RFID Tags Disadvantages

- Higher Cost: Because active RFID tags include a battery and other capabilities, they cost more than passive ones. For companies needing to use lots of tags, this can make them less appealing.

- Limited Battery Life: Active RFID tags have limited lifetime since they run on batteries. Periodic battery replacement can raise maintenance expenses, particularly in cases when tags are used in difficult-to-reach areas.

- Larger Size: Because of their built-in battery, active RFID tags are often heavier and less suited for delicate or small objects. Their greater weight might also restrict their placement choices, particularly in settings with limited space.

What Is An Active RFID Tag?

Active RFID tags are usually used in industrial settings either for open-yard tracking or active RTLS tracking inside a factory. Since almost no guidelines exist for their usage, active RFID is only used in particular niche industrial applications. Price-wise, this kind of tag can range greatly, costing anything from tens of dollars to hundreds of dollars for every tag.

So, What's The Difference Between Passive and Active RFID Tags?

Generally speaking, a shorter read range is a benefit; this will help you to be sure the tagged item is right in front of the reader or you. Using a handheld RFID reader, this is especially helpful when doing a quick stock check across several tagged items.

| Feature | Passive RFID Tags | Active RFID Tags |

| Power Source | No onboard power, uses reader energy | Battery-powered |

| Read Range | Short (up to a few metres) | Long (up to hundreds of metres) |

| Cost | Low (cost-effective for large-scale use) | High (more expensive) |

| Size | Small and lightweight | Larger and bulkier due to battery |

| Lifespan | Virtually unlimited (no battery) | Limited by battery life (up to 5-10 years) |

| Signal Interference | Prone to interference from metals and liquids | Better performance, less interference |

| Data Storage | Limited data capacity | Greater data storage capacity |

| Maintenance | Minimal, no battery replacement needed | Requires periodic battery replacement |

| Real-Time Tracking | Not suitable for real-time tracking | Ideal for real-time tracking |

| Best Used For | Short-range applications, inventory control | Long-range tracking, high-value assets |

| Environmental Suitability | Less effective in harsh environments (metal, liquid) | Effective in harsh environments (metal, liquid) |

Other Things To Consider

Bluetooth beacons, or BLE tags, are a type of active RFID tag, but somewhat confusingly, they are typically not referred to as such. BLE tags are much more consumer-oriented and can communicate with most modern smartphones. By utilising the smartphone as the reader, this significantly reduces the cost and complexity of the entire infrastructure. However, BLE technology is still in its infancy and requires a significant drop in cost for it to become ubiquitous.

Try itemit

Choose a better way to track your assets. Start your free 14-day trial now!

Frequently Asked Questions

How much does an RFID tag cost?

Does RFID need a battery?

Keep Learning

itemit Blog

Tips, guides, industry best practices, and news.

What Is RFID Tracking?

What exactly is RFID tracking and how can it help your business every single day? What are the benefits? Read this post to find out!

Why Tracking Assets Via A Barcode Is Invaluable

Why is tracking assets via a barcode so invaluable and how can IT inventory software help? Read this article now to find out!

Use QR Code Asset Tracking To Keep Your Business Organised

Read this article to find out how QR code asset tracking can help keep your business organised. No matter what type of business you run, QR codes can help!