The QR tag has become a feature of modern life. They were to be found on brochures, flyers, and posters, and even on business cards that were connected directly to websites upon scanning. Actually, each one of us has our QR scanner in our pocket – a smartphone! Perhaps you’re aware that you can use QR code tags for tracking assets, but do you really understand exactly how they work and what they can do? Learn about everything QR code tags have to offer from this ultimate guide.

What is a QR Code?

A Quick Response Code, or a QR code as it is commonly referred to, is a two-dimensional barcode capable of storing information such as URLs, text, or contact details. It was developed in 1994 by Denso Wave, a Toyota subsidiary, for tracking parts in vehicle manufacturing. In the context of QR codes vs barcodes, they are different because they have a much higher storage capacity and can be read from any direction. It was the creator of the QR code, Masahiro Hara, who set out to develop a code that could be read quickly and reliably; the name is Quick Response.

A QR code is made up of black and white squares set on a grid – the structure of a QR code. These patterns involve information about the QR code intended to be read by a scanner, which will understand what is encoded in the matrix. A regular barcode normally holds data in only one dimension, but QR codes have the capability to do so in two dimensions, enabling them to store more complex information.

How Do QR Tags Work?

How do QR codes work, technically? When a camera scans a QR code tag, it captures the arrangement of black and white squares. Then, the scanner software processes this image to tell which modules represent data and which serve a functional purpose. Then, this data is extracted out and translated back into its original form, whether that be a URL, text, or another type of information.

The Use of QR Tags

QR tags are immensely popular nowadays, and their square-shaped barcodes make their way into each and every transaction. From retail and marketing to inventory management and asset tracking, the usage of QR asset tags has been voluminous. QR codes proved handy in containing the spread of COVID-19 during the recent pandemic by allowing contactless transactions and providing a lead for contact tracing.

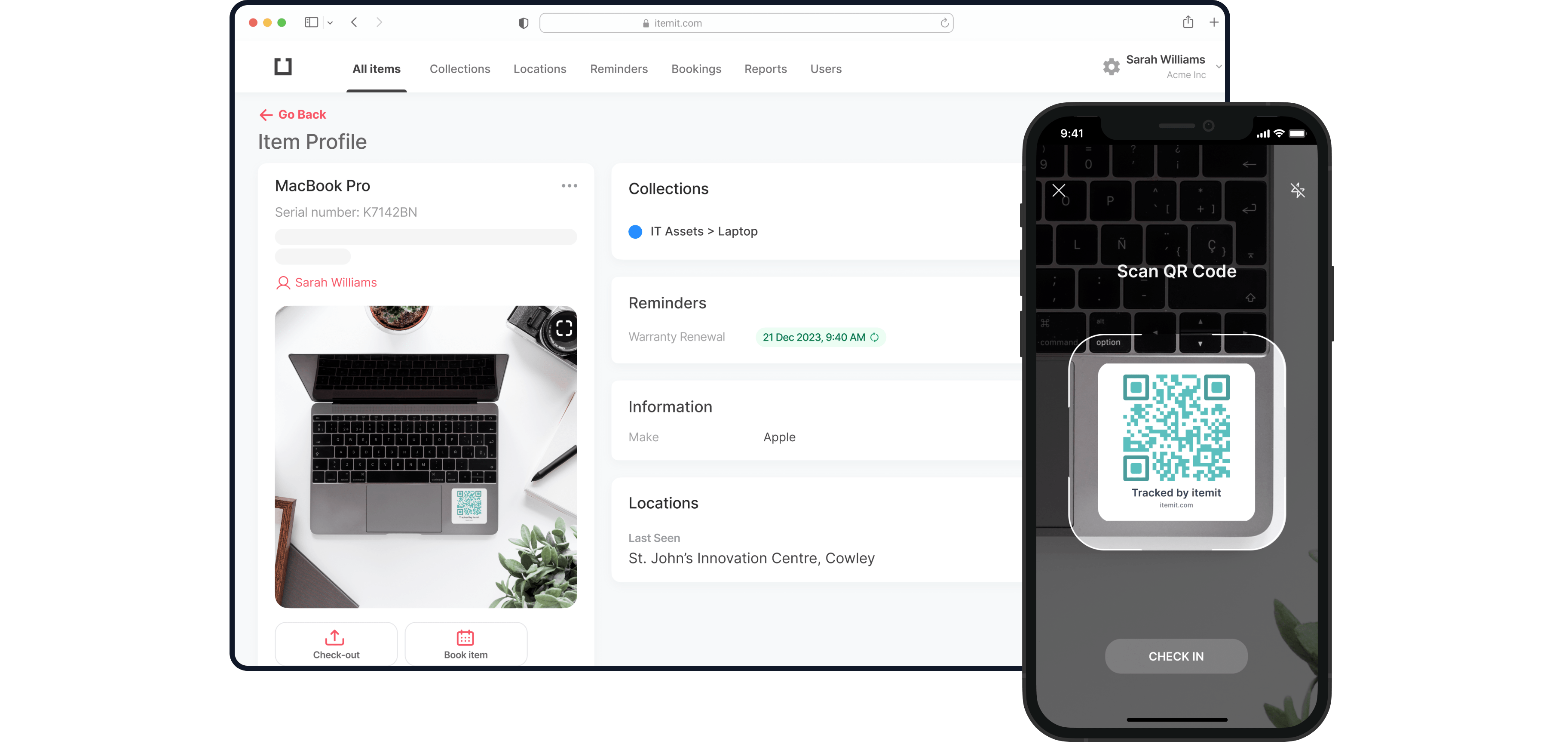

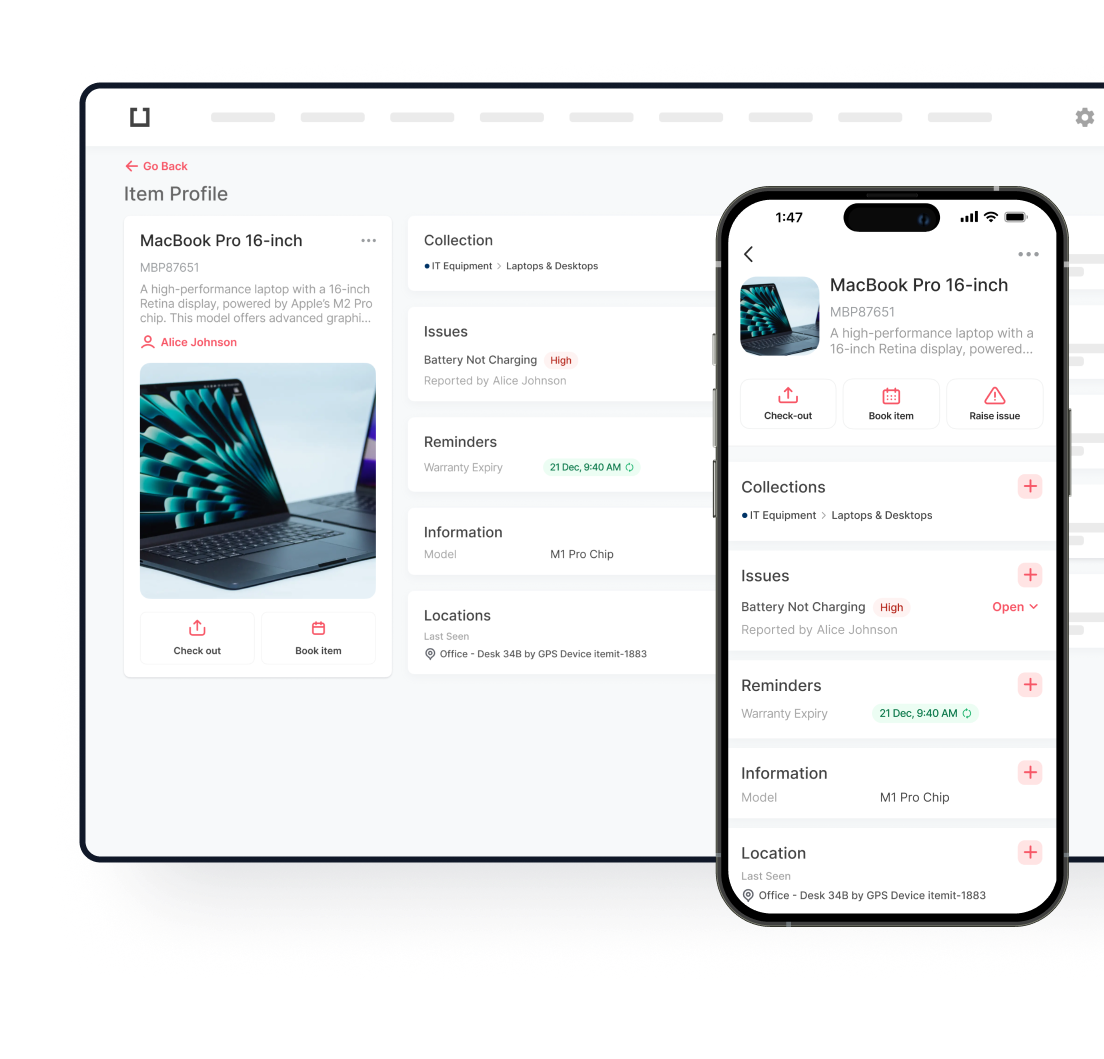

QR code tags are helpful in asset management, as they could help keep track of items across various locations. Be it office equipment, manufacturing tools, or rental assets, QR tags help make sure that the assets are found with ease, monitored, and accounted for. When attached to a physical asset, the scanning of the tag opens up access to associated data, making asset management swift and easy.

There are lots of reasons to use QR codes in tracking your assets. From ease in creating to the less amount of equipment required to use them, they could be very simple in asset tracking systems. Let’s dive deeper into some advantages of QR code tags!

Benefits of QR Tags for Asset Tracking

Cheap and Simple Production

Because of their simplicity, QR code tags are cheap to produce, and because of their 2D nature, they are able to be printed onto a range of materials. In comparison with a standard barcode, a QR code is able to house more information in a much smaller space. This provides a discreet yet effective tracking solution that can easily be hidden out of sight on assets that have limited real estate space.

No Special Equipment Required

One of the great benefits about QR tags is that you do not have to invest one single cent in special equipment, just to be able to scan them. In fact, most smartphones, which exist today, have already been fitted with a camera and even the capability of scanning QR codes, both of which will definitely enable anyone to interact with a QR code tag. This is actually one of the primary reasons that QR code tags are so popular these days.

Easy Integration into Your Asset Management System

It’s fairly simple, actually, to create a QR code asset management system. Pretty much any inventory management and asset management software is designed to function with QR codes; you simply need a way of creating them. Once you have created your QR code tags, they can then be linked through your asset management software, which will provide a seamless way of tracking and managing your inventory.

Durable and Damage Resistant

One of the worst things that could happen to an asset tag would be when it has worn out and becomes unreadable. This may lead to serious delays and inefficiencies within a workforce. Fortunately, QR code tags are quite durable, and even if they are up to 30% damaged, with error correction technology, they can still remain scannable. Such resilience makes the QR tags ideal in places like construction sites or warehouses, where wear and tear are something mundane.

Versatility in Application

Another important advantage with QR code tags is their adaptability. This tag can be attached to almost any surface: plastic, metal, wood, and even fabric. They can be printed in the form of stickers, embedded on metal, and embedded into labels. This flexibility of QR tags makes them suitable for an enormous array of industries: healthcare, manufacturing, education, and logistics.

QR Code Technology and Standards

The technology supporting QR code tags depends upon a set of standards, all of which ensure that there is uniformity reliably across many ways. The QR code standard regulates how QR codes should be formatted, generated, and scanned. The standards developed by ISO mean that QR codes can be utilised universally without problems in compatibility.

The structure is further subdivided into sections, each serving a particular purpose of the QR code. For example, the Finder Pattern, located at three corners of the code, helps the scanners in locating and orienting the QR code. The timing pattern helps determine the data module grid, while the alignment pattern helps correct the distortion when the code is read at an angle. These structural features enable the immediate and accurate scanning of QR codes, a very important aspect of their effectiveness in tracking assets and other uses.

Types of QR Tags for Asset Tracking

Not all QR code tags are created equal. There are different types of QR tags available, depending on the intended use and environment. The most common types include:

- Vinyl QR Code Stickers: These are the most basic and economical type of QR tags. They are suitable for indoor environments and can be easily affixed to most surfaces.

- Anodised Aluminium QR Tags: These are designed for durability and are ideal for harsh environments. The anodised aluminium ensures the QR tag is weather-resistant, making it perfect for outdoor use or in conditions where the tag may be exposed to chemicals or abrasion.

- Embedded QR Code Labels: These tags are embedded directly into the product or asset during manufacturing. They are highly durable and tamper-proof, making them ideal for high-value or sensitive assets.

How to Create QR Code Tags for Asset Management

Creating QR code tags for asset management is a straightforward process. You can use online QR code generators to produce the code, which can then be printed on a variety of materials depending on your needs. Here’s a step-by-step guide to creating your QR tags:

- Choose an Online QR Code Generator: There are many online tools available that allow you to create QR codes for free or for a nominal fee. Make sure to choose a generator that allows you to download high-resolution codes suitable for printing.

- Input the Data You Want to Encode: This could be a URL linking to your asset management system, text, or any other relevant information.

- Customise the QR Code: Some QR generators allow you to customise the code’s colour, add logos, or even create dynamic QR codes that can be updated after printing.

- Download and Print the QR Code: Once generated, download the QR code in the desired format (such as PNG or SVG) and print it on your chosen material—vinyl, aluminium, or standard label paper.

- Attach the QR Code Tag to Your Asset: Ensure the tag is affixed securely to the asset in a location that is easily accessible for scanning.

Tips for Using QR Code Tags Effectively

To get the most out of your QR code tags for asset tracking, follow these best practices:

- Ensure Proper Placement: Attach the QR code tag in a location that is easily accessible for scanning. Avoid areas prone to dirt or damage, which may affect the code’s readability.

- Use High-Quality Materials: If your assets are used in harsh conditions, opt for durable materials like anodised aluminium to ensure the tags last longer.

- Regularly Update QR Code Information: If your QR code tags are linked to dynamic data, make sure the information is updated regularly. This will ensure that users have access to the most current asset details.

- Test Before Implementation: Test the readability of your QR code tags using different devices before rolling them out on a large scale. This helps identify potential issues early and ensures smooth scanning in the field.

QR Tags in Different Industries

QR tags have applications across a wide range of industries. Now, let’s try exploring how different sectors are using QR tags to automate their system for smooth functioning:

Healthcare

QR code tags are able to track medical equipment, patient records, and pharmaceuticals in the healthcare industry. Attaching QR tags to medical devices allows hospitals to assure timely maintenance and proper accounting of their equipment. QR code tags can be used on patient wristbands so that health professionals have immediate access to patient information, reducing the possibility of errors and improving patient care.

Manufacturing

These QR code tags are applied to manufacturing for raw materials tracking, work-in-progress items, and finished products. This can be used by the manufacturer in monitoring the material as it moves through the production process, ensuring accountability for each component and adherence to production schedules. QR tags can also be used in quality control, whereby an inspector scans the product for detailed information about each item.

Retail

QR code tags for inventory management, product information, and customer contact. QR tags will be affixed to merchandise for scanning by customers for extended information such as product specifications, product reviews, or promotions. Retailers will use QR tags in streamlining the efficiency of inventory management whereby staff can quickly scan and update the stock level of an item.

Logistics and Supply Chain

QR code tags are used for logistic supply and chain management purposes in tracking shipments, inventory levels, and warehouse operations. QR tags ensure that products are correctly tracked as they make their way along the supply chain, minimising losses from loss or misplacement. They further allow insight into real-time inventory visibility for informed decisions on the replenishment of stock.

Education

Educational institutions are also using QR code tags to improve the learning experience and further facilitate asset management effectively. QR tags can be used in libraries to inventory books and other resources for easy tracking among students and staff. QR codes in classrooms can grant students access to digital content like videos, quizzes, or extra reading by scanning the code with their smartphones.

Common Challenges with QR Code Tags and How to Overcome Them

While QR code tags have several advantages, there are two or so challenges that come along with using them. Here are some common challenges and some tips regarding how to overcome them:

Damage and Wear of Tags

QR code tags can also get destroyed due to time, particularly in unfit conditions. The type of tag material should be correct according to the environment it will be used for, in this case. For example, anodised aluminium tags last longer and so can support extreme weather conditions and so is apt for outdoors or harsh industrial usage.

Poor Placement

Poor positioning of QR code tags renders them cumbersome to scan. The tags should be placed in positions that are easy to access and which would not get easily destroyed or blocked. For instance, it is best to avoid placing a tag on an object that could be buried by items or covered with dust, dirt, or grime during its lifetime.

Poor Printing

Poor quality printing also leads to QR code tags that can’t be scanned. Due to this fact, high-resolution printing should be used in order to present a clear and readable QR code. Also, the use of contrast between the code and the background will enhance the efficiency of scanning.

Lack of User Training

Unless the user is familiar with scanning QR code tags or accessing information they carry, full benefits of QR tagging may not be realised. Training and clear instructions in using the QR codes go a long way in making all users comfortable using the technology and exploit it for their benefit.

Security Considerations for QR Code Tags

While QR code tags are easy to use and versatile, it is important to take security into account when using QR code tags for the tracking of assets. Here are a few security tips you might want to consider:

Use Secure URLs

If your QR code tags link to something online, make sure the URL is secure; in other words, they should use HTTPS so that sensitive information will not be intercepted by unauthorised parties. Limit access to sensitive information.

Limit Access to Sensitive Information

Not all information should be available to anyone who can scan a QR code tag. Sensitive asset information should be protected using authentication or password protection so that it is only provided to those with access to that level. Only authorised personnel should have access to and/or update the asset information.

Monitor and Track Scans

Knowing the number and location of scans can already locate potential areas of where it could have been breached. Many asset management systems have tracking features that enable you to monitor when and where QR code tags are scanned, adding another layer of security.

Future Trends in QR Code Technology

While QR code technology is still evolving, some of the trends one may soon observe are the combination of blockchain with QR codes to ensure secure and tamper-proof asset tracking. This would be a very useful service for cases with high-value assets or supply chain management where data integrity is of utmost importance.

Another emerging trend is the usage of QR code tags within AR. For example, consider scanning a QR code on an asset and receiving a 3D visual in return on how to operate or repair the asset. This kind of innovation could very well totally revamp training and maintenance practices across industries.

Last but not least, there is an emerging trend toward what is called dynamic QR codes that can be edited after they have actually been printed. That grants an enterprise an opportunity to change the information encoded in the QR tag without having to replace the actual physical tag, hence providing better and less expensive management of its possessions.

itemit’s QR Tags

Therefore, a QR code tag is a very powerful tool for tracking any asset effectively, efficiently, and economically, including various models for different applications. From ease of production to durability and integration with other system components, the QR tag has proved invaluable in scores of diverse industries. Be it managing office equipment, rental assets, or high-value tools, QR code tags offer a modern solution that makes it easier than ever to track and manage your assets.

Here at itemit, we have various kinds of QR code tags intended for different asset management needs. Vinyl QR code stickers are great economically for managing tags indoors. Anodised aluminium tags will serve users who want more strength. These robust tags will resist extreme temperatures, harsh chemicals, and physical abrasion, hence suitable for outdoor applications or industrial sites.

Our QR tags range in size from 15 to 50 millimetres, so you’ll be able to make a good choice depending on the asset concerned. Whether you need a tag discreetly placed on something small or something a little larger for heavy machinery, itemit has you sorted.

If you would like to learn more about how itemit’s QR code tags can help streamline the process of tracking your assets efficiently, please contact our team at team@itemit.com. Alternatively, fill in the form below to start your very own 14-day free trial.

Try itemit

Choose a better way to track your assets. Start your free 14-day trial now!

Construction projects fail most often due to poor planning around materials—not design flaws or worker shortages. Material management in construction determines which projects finish on time and which drain budgets through waste and delays. Mastering this discipline separates profitable contractors from those who constantly firefight supply issues.

Key Takeaways

- Material management in construction separates profitable projects from budget disasters. Success requires coordination across procurement, logistics, storage, and tracking.

- Accurate planning prevents both shortages that halt work and excess inventory that wastes capital. Smart contractors order materials to arrive just when crews need them, minimising storage time and handling costs.

- Supply chain materials management demands relationship-building with reliable suppliers who provide priority service during shortages and problem-solving when issues arise.

- Material control through organised storage, clear documentation, and accountability systems reduces losses from theft, damage, and simple misplacement. These improvements flow directly to bottom-line profitability.

- Technology works best when it responds to specific operational challenges rather than being adopted for its own sake. Choose systems that solve your actual problems, train teams thoroughly, and measure results through relevant metrics.

- Itemit digital tracking systems improve accuracy while reducing labour costs associated with manual inventory management. Real-time visibility into material locations and equipment status prevents the time waste of searching for misplaced items.

What Is Material Management?

Construction projects rely on RFPs when complexity demands more than simple price comparisons. These documents reveal contractor thinking, proposed schedules, safety programs, team qualifications, and problem-solving approaches that help predict project success. A hospital expansion requires different evaluation criteria than a parking lot repaving. RFPs accommodate this nuance.

Legal requirements mandate RFPs for many public sector projects. Government agencies must demonstrate transparent, competitive procurement in construction. Taxpayer dollars deserve documented, defensible selection processes. Private organizations often mirror these practices because they recognize the risk mitigation benefits. Even without legal obligations, smart project owners appreciate the protection RFPs provide.

RFPs help project owners avoid costly surprises through thorough vetting. Does the contractor understand site constraints? Have they managed similar projects? Can they demonstrate financial stability? Do they carry adequate insurance? These questions get answered before contracts are signed, not after problems emerge mid-construction.

The competitive yet fair evaluation process benefits everyone. Contractors compete on merit across multiple dimensions—technical approach, schedule, qualifications, and price. This prevents the "race to the bottom" where unrealistically low bids win despite inadequate capability. Fair competition attracts better contractors who know they won't lose to unqualified bargain bidders cutting corners to win work.

Large-scale projects exceeding $100,000 typically warrant this formal approach. Design-build delivery methods benefit from RFPs since contractors propose both design and construction approaches. Projects requiring specialised equipment tracking systems or sophisticated construction project management also justify the detailed evaluation that RFPs enable.

Procurement in construction has evolved significantly, yet the core principle remains unchanged: match qualified contractors with appropriate projects through structured, transparent processes.

How Does an RFP Differ from RFQ and RFI?

Construction procurement involves several document types, each serving distinct purposes.

An RFP (Request for Proposal) asks contractors to propose comprehensive solutions including methodology, project understanding, team credentials, schedule approach, and pricing. What is a RFP proposal in this context? It's a complete package demonstrating how and why a contractor should be selected. The proposal might span 50 to 200 pages depending on project scale.

An RFQ (Request for Quotation) focuses primarily on price. The scope is already well-defined with detailed specifications, drawings, and material lists. You're asking "What will this cost?" rather than "How would you approach this?" RFQs suit straightforward projects where work is clearly understood.

An RFI (Request for Information) comes earlier in the process. This preliminary document gathers general information about contractor capabilities before committing to a formal RFP. No pricing or detailed proposals required—just background information.

Many organisations employ a staged approach. First, they issue an RFI to identify potential contractors. Next, they narrow the field through an RFQ. Finally, they send the full RFP to a shortlist of three to five qualified firms. This saves everyone effort—unqualified contractors don't waste time on proposals they won't win, and owners don't wade through dozens of inappropriate submissions.

What Components Should Every Construction RFP Include?

A strong RFP document contains specific elements that enable contractors to submit intelligent, comparable proposals. Missing components create confusion, incomparable submissions, and selection difficulties.

Project Overview and Objectives: Explain what you're building, why it matters, and what success looks like. Background information helps contractors understand your priorities. Are you driven by schedule constraints? Budget limits? Quality requirements? Ambiguous scopes doom projects from the start. A community centre RFP might emphasise accessibility and sustainability, while a warehouse renovation focuses on minimal operational disruption.

Technical Specifications: Include architectural drawings, engineering plans, material requirements, and quality standards. Specifications should be thorough yet flexible enough to encourage innovative approaches. For projects involving specialised equipment, explain any requirements for tracking construction tools or managing assets throughout the project lifecycle.

Timeline and Milestones: State your desired completion date, key milestones, and any immovable deadlines driven by external factors like seasonal weather, occupancy requirements, or regulatory dates. Give contractors adequate response time—two weeks minimum for standard projects, four to six weeks for complex work. Rushed proposal deadlines yield rushed, inadequate proposals that serve nobody well.

Budget Parameters: Some RFPs disclose budget ranges, helping contractors tailor solutions to financial reality. Others leave budgets unstated, preferring to see what the market delivers. Both approaches have merit depending on your strategy. Disclosed budgets prevent wasted effort on impractical proposals but might anchor pricing artificially high.

Submission Requirements: Specify exactly what you want and how you want it. Required documents might include insurance certificates, bonding capacity, safety records, references, key personnel resumes, and project schedules. Format expectations matter—are you accepting physical binders, PDF uploads, or both?

Evaluation Criteria: When contractors understand your scoring methodology, they emphasise the right elements. Will price represent 30% of your decision or 60%? How much weight do you assign to experience, safety record, or proposed methodology? Publish your evaluation matrix so contractors can align their proposals with your priorities.

Contractual Terms: Brief but clear information about contract type, payment schedules, change order procedures, and standard terms protects everyone.

Safety and Compliance: Modern contractors using sophisticated asset management systems to track equipment, certifications, and maintenance schedules demonstrate organisational maturity that predicts project success. Safety isn't just about avoiding injuries—it reflects overall operational quality.

What Steps Make Up the RFP Process from Start to Finish?

The journey from RFP concept to signed contract follows eight key phases:

Step 1: Project Definition - Project owners meet with stakeholders to nail down requirements, budget, timeline, and scope.

Step 2: RFP Document Creation - Procurement teams or project managers draft the comprehensive document, which undergoes legal review and stakeholder approval.

Step 3: Contractor Identification and Distribution - The RFP is sent to either pre-qualified contractors or posted publicly for open bidding.

Step 4: Pre-Proposal Conference and Q&A Period - Smart owners hold optional site visits and pre-proposal meetings, documenting all questions and answers in official addendums.

Step 5: Proposal Submission - Contractors submit their proposals by the stated deadline.

Step 6: Evaluation and Scoring - Teams assess proposals against published criteria, documenting scores and justifications. Evaluators particularly examine how contractors demonstrate systematic approaches to resource coordination, including their capacity to track heavy construction equipment and manage complex logistics.

Step 7: Interviews and Final Selection - Top-scoring contractors receive interview invitations to demonstrate team chemistry and clarify proposal elements.

Step 8: Contract Negotiation and Award - Final terms are refined, details are clarified, and once both parties agree, contracts are executed and project kickoff begins.

What Best Practices Lead to Successful RFPs?

Excellence in RFP processes requires attention from both sides.

For Project Owners Creating RFPs:

Clear Communication Beats Perfection - Straightforward language works better than legal jargon overload. Address difficulties upfront, inviting contractors to propose solutions.

Realistic Timelines Matter - Provide adequate response time matched to project complexity. Simple renovations might need two weeks while major infrastructure projects deserve four to six weeks minimum.

Be Specific About Evaluation - Publish your evaluation matrix showing weighted criteria. Transparency improves proposal quality because contractors emphasize elements you actually care about.

Include the Right Details - Balance between too much and too little information. Clear requirements with room for contractor expertise to shine through works best.

Allow Questions and Site Visits - Open communication channels prevent misunderstandings. Document everything and share equally with all bidders.

For Contractors Responding to RFPs:

Read Everything Before Starting - Skimming leads to non-compliant proposals that get rejected immediately. Missing a single mandatory form might disqualify your entire submission.

Answer What's Actually Asked - Address every requirement methodically. Make evaluators' jobs easy by directly answering stated questions in the order asked.

Demonstrate Project Understanding - Reference specific details from the RFP, site conditions, or concerns raised during pre-proposal meetings. Customization signals genuine interest and capability.

Highlight Your Differentiators - Explain what makes your approach better. Demonstrate systematic approaches to rfp in construction project management, including proven methods for managing assets, coordinating teams, and maintaining schedules.

Make Evaluation Easy - Use clear formatting, executive summaries, and logical organization. Professional presentation signals professional project execution.

What Common Mistakes Should You Avoid in the RFP Process?

Even experienced organizations stumble. Learning from common errors saves time, money, and relationships.

Owner Mistakes: Setting unrealistic expectations about timeline or budget attracts desperate contractors, not qualified ones. Vague scope definitions force contractors to guess at requirements. Changing requirements mid-process without proper addendums frustrates contractors. Evaluation criteria that don't match stated priorities erode trust.

Contractor Mistakes: Generic, template-based proposals that don't address project specifics get spotted immediately. Failing to ask clarifying questions during the Q&A period costs opportunities. Underpricing to win bids creates problems for everyone. Poor organization of proposal materials frustrates evaluators. Ignoring submission requirements risks immediate disqualification. Not demonstrating systematic approaches to construction project management including equipment tracking and resource coordination misses opportunities to showcase organizational sophistication.

How Can Technology Improve the RFP Process?

Construction procurement has joined the digital age, bringing efficiencies that were impossible a decade ago.

Digital Platforms streamline distribution, track downloads, manage questions, and organize submissions. Version confusion evaporates when everyone accesses the same cloud-hosted document. Addendums get distributed automatically rather than relying on email chains that might miss someone. Contractors can download documents 24/7 without waiting for business hours or physical mail delivery.

Collaboration Tools ensure stakeholders see the latest RFP versions during drafting. Internal teams can comment, suggest edits, and track changes without creating version conflicts. During evaluation, these tools let scoring committees share assessments efficiently and discuss proposals in real-time, even when team members work remotely.

Evaluation Software reduces bias and documents decision-making processes thoroughly, protecting against challenges and improving decision quality. Each evaluator completes standardized forms scoring defined criteria. Software aggregates results, identifies outlier scores requiring discussion, and generates reports justifying final selections.

Asset Management Systems help contractors gain competitive advantages during evaluation. Project owners recognize that organized resource management correlates with on-time, on-budget delivery. Contractors who can show systems for monitoring equipment location, maintenance schedules, and utilization rates signal operational maturity that predicts project success. These same systems that help win bids also support delivery throughout actual construction.

For construction project management overall, integrated platforms connecting procurement, scheduling, equipment tracking, and team communication create visibility that manual methods can't match. The data these systems generate helps contractors learn from each project, continuously improving their operations and proposal quality.

Next Steps

RFPs serve as the foundation for successful construction partnerships by establishing clear expectations before significant commitments are made. Success comes from clear communication, thorough documentation, and systematic approaches to construction project management that extend from initial procurement through final delivery.

The procurement in construction landscape continues evolving with technology making processes more efficient while maintaining transparency and fairness. Whether you're issuing or responding to RFPs, the principles remain constant: understand requirements deeply, communicate clearly, demonstrate capability convincingly, and evaluate fairly. The contractors who win competitive RFPs often share one trait—they've invested in systems and processes that enable consistent performance, showing organizational discipline in their proposals and delivering results on job sites.

Try itemit

Choose a better way to track your assets. Start your free 14-day trial now!

Keep Learning

itemit Blog

Tips, guides, industry best practices, and news.

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.