Equipment tracking gives you an edge over your operations. You’ll be outnumbered by your assets and so knowing what you own, where it is, and who is using it is essential. Knowing this information provides you with many business-related benefits.

Overall, when you track your equipment, you can speed your operations up. Therefore, you can deliver your projects on time and under budget by having a much clearer view of what you can use and what conditions your assets are in.

What Is Equipment Tracking?

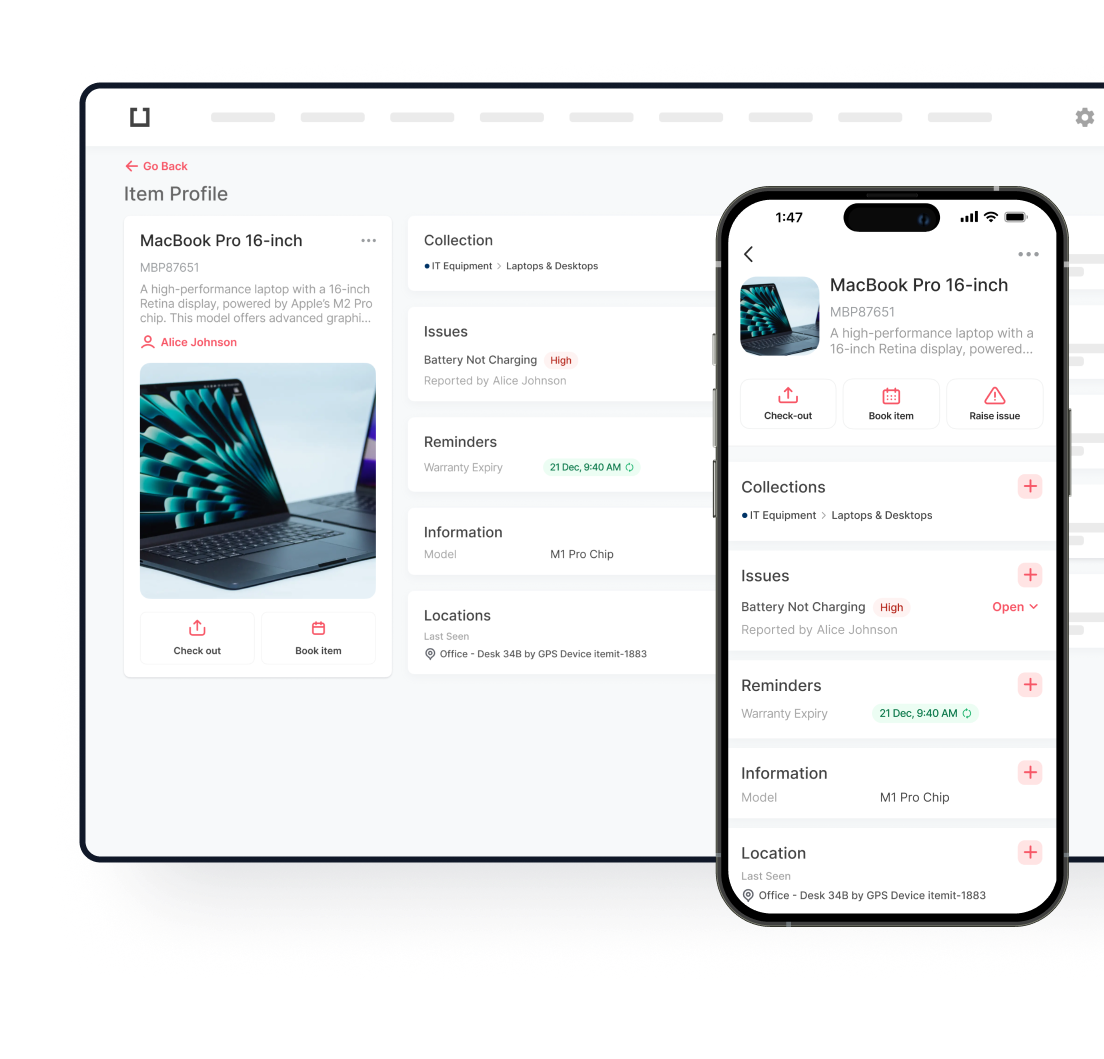

Equipment tracking is the procedure of logging your equipment as a unique asset and tracking it. Therefore, you’ll be able to track an individual laptop, for example.

The main benefit is that having a granular view of your assets allows you to add specific information to them. All of this information builds your fixed asset register as you go, too, allowing you to audit your assets much more effectively.

So, what are the main benefits of equipment tracking?

More Accountability

Having a robust asset register gives your business more accountability over what you own. As everything is logged, tracked, and monitored, there are fewer gaps in your accounting and auditing operations.

Logging unique assets also reiterates the value of your equipment. Having something specific on an asset register and seeing how that unique asset performs and functions increases the responsibility over that asset.

Therefore, you get a much more accountable workforce by using equipment tracking procedures.

Lose Fewer Assets

There are a few ways that asset tracking software helps you lose fewer assets. The first is through the use of asset tags.

You’ll be able to track the locations of your assets using asset tags. Every unique asset will have a tag stuck onto it, then this physical asset will be linked to its digital profile using the tag.

This way, every time you scan an asset’s tag, the last seen location will update and the asset’s digital profile will open in your asset tracking app simultaneously.

However, the additional accountability you have over your asset register also allows you to mitigate asset loss. As you’ll reduce the chance of ghost and zombie assets, you know which assets you’re looking for when you’re running an audit.

Export And Use Your Fixed Asset Register

Your fixed asset register has many benefits. Being able to create one automatically as you track your assets and export it for a variety of different purposes is essential.

Therefore, you’ll be able to use your fixed asset register (a register of all of your equipment) for insurance purposes, as you’ll get a pdf report with no gaps and all the information you need to ensure cover.

The lack of gaps is also essential for financial purposes, as having a robust fixed asset register means that you can prove ownership and expenses when you’re getting necessary tax breaks.

To find out more about how equipment tracking can benefit your business, you’ll be able to book a demo using the button below.

You can also contact the team at team@itemit.com or call us at 01223421611. If you fill in the form below, you can also start your 14-day free trial of itemit!

Why not check out these blogs:

Is Asset Tracking Software Better Than A Spreadsheet?

Why Fixed RFID Is The Future Of Asset Tracking

Practical Uses For Your Fixed Asset Register

Start Using Better Equipment Tracking Software!

Try itemit

Choose a better way to track your assets. Start your free 14-day trial now!

Keep Learning

itemit Blog

Tips, guides, industry best practices, and news.

What Is Visual Inspection? Definition, Methods, and Best Practices in Manufacturing

Learn the meaning of visual inspection, its methods, tools, and applications in manufacturing. Discover best practices for accurate quality control.

5 Tips For Better Equipment Management

Equipment management is vital to ensuring your business’s smooth operations. Discover how to get the most out of your hard-earned investments.

What is equipment booking software and do I need it?

What is equipment booking software? Should you use it if you’re hiring out or sharing equipment? How can itemit help you book equipment?