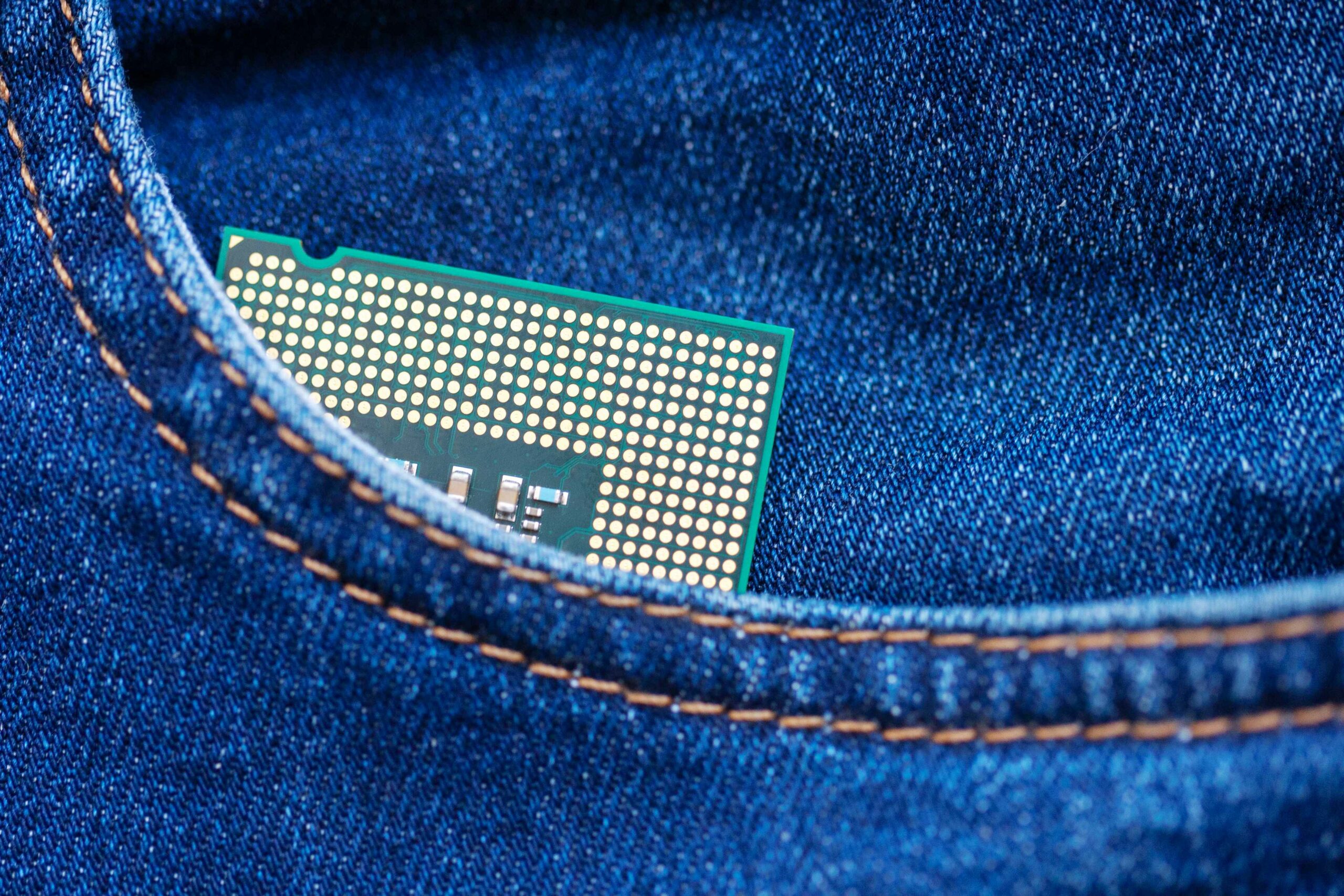

Radio frequency identification (RFID) tags are little items that have a big impact on smart supply chains, keeping track of assets, and keeping track of inventory. But it’s quite crucial to put things in groupings. Diverse applications are possible because of the diverse power sources, frequency ranges, memory capacity, and read ranges. You should try each tag in a real-world setting before you choose a solution. This full lesson will educate you about the many kinds of RFID tags and how they function.

What Makes RFID Tags Different?

The underlying idea behind every radio frequency identification tag is the same: it stores data and communicates it wirelessly when scanned. There are a number of critical physical and technical factors that affect how each tag works and how well it operates in a certain environment. At its most basic level, one of these things to think about is the difference between Passive RFID and Active RFID. These differences affect how well something works, how reliable it is, and how useful it is; they are not only for looks.

Power Source

This is one of the most fundamental differences. RFID tags can be passive, active, or semi-passive.

- Passive tags have no internal power supply; they rely entirely on energy from the reader’s electromagnetic field to activate and respond.

- Active tags contain their own battery, which powers both their microchip and their ability to broadcast a signal independently.

Semi-passive (or battery-assisted passive) tags have a battery that powers the chip, but the tag still requires a signal from the reader to initiate communication.

The choice of power source affects not just the tag’s range but also its size, weight, price, and maintenance requirements.

Frequency Range

RFID operates across several frequencies—low frequency (LF), high frequency (HF), and ultra-high frequency (UHF). The selected frequency influences the tag’s read range, speed, and sensitivity to environmental interference.

- LF tags (125–134 kHz) are excellent in environments with high moisture or metal interference but have short read ranges.

- HF tags (13.56 MHz) strike a balance between range and data rate and are widely used in access control and contactless payment.

- UHF tags (860–960 MHz) offer long read ranges and fast data transfer but are more prone to disruption from liquids and metals.

The match between tag frequency and application environment is critical to ensure reliable communication.

Passive RFID Tags

When an RFID reader emits a radio signal, a passive tag’s antenna captures that energy and uses it to activate the chip inside. Once powered, the tag transmits its stored data back to the reader. Because this energy transfer only occurs when a reader is nearby, the tag remains inactive most of the time—conserving cost and extending usability.

Read Range

- UHF (Ultra High Frequency): Typically up to 10 meters (around 30 feet) under optimal conditions.

- HF (High Frequency): Around 1 meter.

- LF (Low Frequency): Usually no more than 10 centimeters.

The read range depends not just on frequency but also on tag size, reader strength, and environmental factors.

Lifespan

Since there’s no battery to deplete, passive tags can last for many years—often the life of the item they’re attached to. As long as the antenna and chip remain undamaged, they can be reused indefinitely.

Cost

Passive RFID tags are the least expensive of all tag types. Mass production brings the cost down to as little as a few cents per tag, making them economically suitable for disposable or short-cycle tracking.

Limitations

- Interference Sensitivity:

These tags struggle in environments with high moisture or metal surfaces. Water absorbs radio waves, and metal reflects them, causing misreads or signal loss. This limits their performance in locations like refrigerated warehouses or metal shelving. - Signal Strength & Data Capacity:

Passive tags have a weaker return signal and limited onboard memory. While sufficient for storing unique IDs or small data packets, they cannot handle complex sensor input or active broadcasting.

Use Cases

Passive RFID tags are the go-to choice in high-volume, short-range applications. Some of the most common use cases include:

- Apparel and footwear tracking in retail environments.

- Library and archive management, where books and documents need fast bulk scanning.

- Inbound/outbound warehouse processing, with thousands of tagged boxes or bins moving through automated conveyors.

- Event ticketing and access control, where disposable tags are embedded in wristbands or badges.

Active RFID Tags

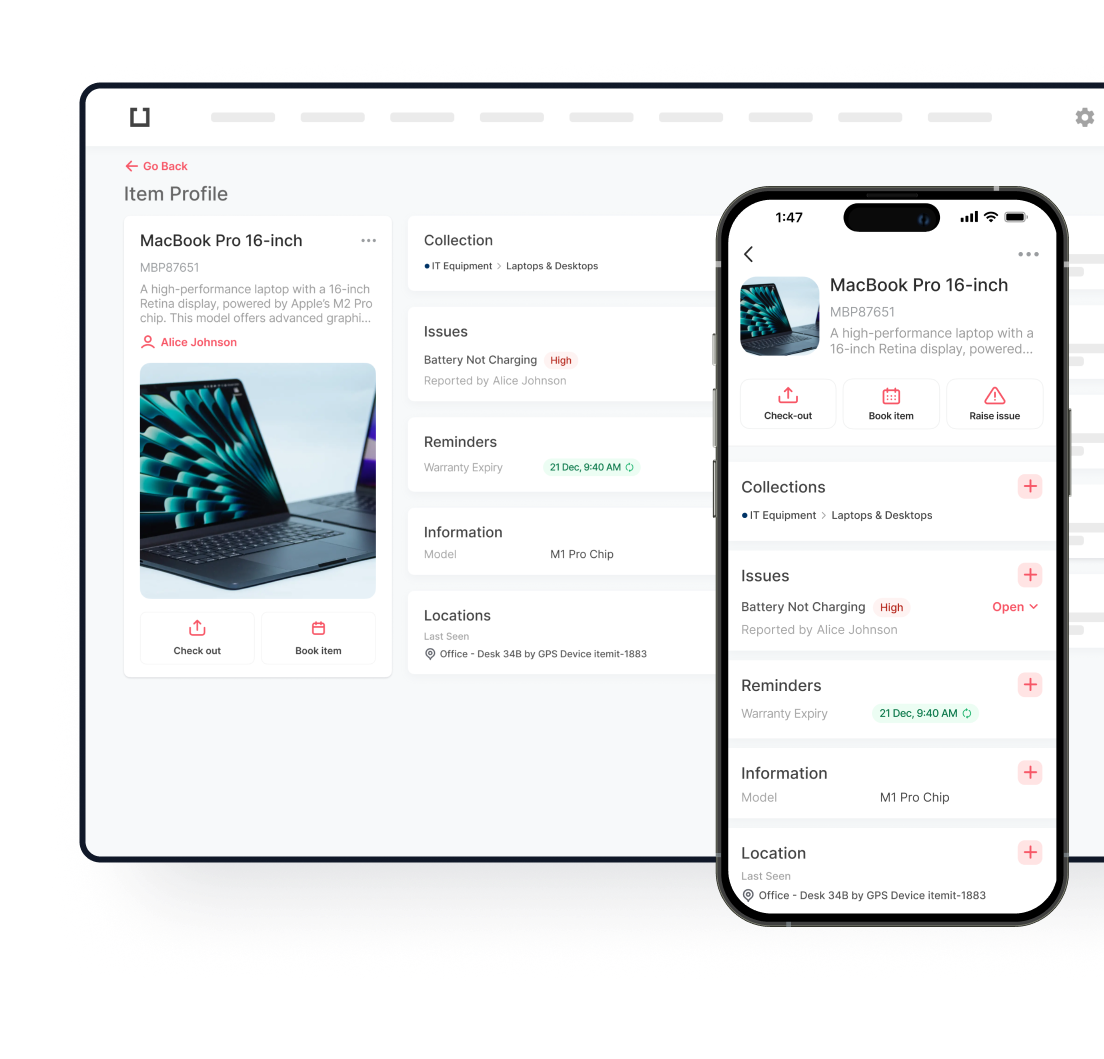

Active RFID tags have an onboard battery, allowing them to broadcast signals without being activated by a reader. These are designed for large-scale asset tracking across wider areas—think shipping containers, vehicles, or industrial tools. RFID asset tracking software processes these signals to provide real-time location updates and movement history.

Key traits:

- Read range: Can reach 100+ meters.

- Power: Battery life spans between 3 to 5 years, sometimes replaceable.

- Cost: Higher due to embedded electronics.

Benefits:

- Real-time tracking in large facilities or across transportation networks.

- Stronger signal allows reliable scanning in challenging environments.

While less common in consumer-facing applications, Active RFID tags are key in defense logistics, hospital asset management, and mining operations.

Semi-Passive RFID Tags

Semi-passive RFID—also referred to as BAP RFID (Battery Assisted Passive)—blends traits of both active and passive tags. These tags use a battery to power the microchip but rely on the reader’s signal to initiate communication.

These tags are valuable for cold chain monitoring, where temperature sensors collect data during transit and transmit it only when queried. RFID semi passive tags often come equipped with environmental sensors, making them fit for logistics involving perishable goods or pharmaceuticals.

Breaking Down RFID Frequency Ranges

Frequency significantly affects the performance of RFID tags types, especially when choosing between:

- Low Frequency RFID (LF)

LF tags can only be read from less than 10 cm away since they only work at frequencies between 125 and 134 kHz. One of their best features is how well they work in places where signals can’t get through, like water and metal. These tags are great for short-range operations when you need to quickly identify someone. They are used a lot for tagging animals, immobilizing cars, and giving people access to buildings. - High Frequency RFID (HF)

These tags work at 13.56 MHz, so you may read them from a distance of up to 1 meter. Library systems, public transit passes, and contactless payment cards all employ HF technology. It works with NFC standards from all around the globe, which is why it’s a common part of telephones and smart cards. The read range is better than LF, but it’s not good enough for industrial or large-scale logistics uses. The signal quality may also decline when it’s near liquids or metals. - Ultra High Frequency RFID (UHF)

Ultra-high frequency (UHF) has a frequency range of 860 to 960 MHz and lets you read from distances of 12 meters or greater. It is used as a standard in applications that need fast speeds and large amounts of data, such automating the supply chain, keeping track of inventory in warehouses, and keeping track of airline luggage. Configured UHF RFID tags and chips make it possible to scan large groups of people quickly and cheaply.

UHF RFID chips and UHF RFID tag formats are central to high-volume industrial applications. They support batch reading and allow scanning thousands of tags per minute—a requirement in large distribution centers.

Tag Shapes and Types: From Stickers to Embedded Sensors

Tag form factors vary as much as their power sources. Some common types of digital tags include:

- Wet Inlays: Adhesive-backed for stick-and-go applications. Used in retail and logistics.

- Dry Inlays: No adhesive; embedded in cards or badges.

- Hard Tags: Encased in durable material for use on tools, vehicles, or heavy equipment.

- Sensor Tags: Include temperature, motion, or humidity sensors.

- Glass Tags: Used for animal implants or scientific tools due to biocompatibility.

Each form factor fits different RFID tags types and functions. For instance, hard tags are typically passive or semi-passive but optimized for rugged conditions. Meanwhile, wet inlays are perfect for shelf labeling or outbound packaging.

How RFID Readers Interact with Tag Types

RFID readers act as the communication link between the system and the tag. They power passive tags, receive data from active or semi-passive tags, and forward that data to backend systems. The performance of RFID tag tracking is only as good as the alignment between tag type, reader configuration, and environmental layout.

Key variables:

- Antenna power and directionality.

- Reader software compatibility with tag chipsets.

- Environmental noise, metallic surfaces, or interference sources.

In retail stores, ceiling-mounted readers monitor foot traffic and product movement in real time. In logistics centers, readers are built into conveyor belts and gateways. Each tag-reader setup must be tested for blind spots and signal reflection, particularly with ultra-high frequency RFID tags.

IoT Integration and Data Flow

RFID tags are not just static ID markers anymore. With IoT integration, they become part of a larger network that tracks, analyzes, and even predicts the movement and behaviour of assets. When an RFID tag scans, its data flows into cloud-based systems, where it’s matched with time stamps, geolocation, and sensor values.

Smart factories and logistics hubs increasingly rely on RFID tag types designed for sensor data collection, not just identification. These tags become nodes in the IoT network, enabling automation at scale.

Try itemit

Choose a better way to track your assets. Start your free 14-day trial now!

Frequently Asked Questions

If there aren’t enough security measures in place, it’s simple to copy RFID tags, especially the cheap passive ones. To reduce this risk, more and more tags and systems are adding password security, mutual authentication, and encryption methods. Cryptographic algorithms and rolling codes are widely employed to make it hard to get to or copy high-security applications like secure ID badges or payment cards.

There may be collisions when many tags respond to a reader at the same time. RFID systems, on the other hand, use anti-collision protocols like ALOHA or tree-based algorithms to solve this problem. Because of these protocols, the scanner can find and read each tag on its own, even in places where there are hundreds of them.

That depends on how the tag is made. If the antenna is bent or damaged, normal paper-based or adhesive inlay tags won’t work anymore. Rugged tags, on the other hand, are made to last in tough situations like vibration, chemicals, and stress. If you need tags that can handle tough circumstances, search for ones with sealed electronics and cases made of industrial-strength material.

4. Is there any concern about privacy or health when radio frequency identification is used in consumer goods?

RFID tags give out extremely low levels of non-ionizing radio waves, which are similar to those of everyday household items. This makes many people think that they are entirely safe to be around. But a lot of people have said they are afraid of being watched or scanned without their knowledge or permission. You may wear RFID-blocking sleeves or turn off tags to keep from being tracked after you buy anything.

5. How effectively do RFID systems perform in cities where signals overlap?

Wi-Fi, Bluetooth, and overlapping frequencies are all things that might cause signal interference in cities. RFID systems frequently employ shielding or frequency hopping when they work in regulated frequency bands to prevent this. A well-planned installation that uses directional antennas and power adjustments will cut down on cross-talk and false readings.

Keep Learning

itemit Blog

Tips, guides, industry best practices, and news.

Everything You Need to Know About 2D Barcodes

Discover everything about 2D barcodes, including how they work, their benefits, and how they are revolutionizing industries and improving business operations

Complete Guide to Asset Lifecycle Management and Its Benefits

Learn about asset lifecycle management and how it helps businesses optimize asset usage, reduce costs, and improve efficiency throughout the asset’s life.

Benefits of Vendor Managed Inventory for Your Business

Learn how Vendor Managed Inventory (VMI) can streamline your supply chain. Explore the key benefits and how it helps optimize inventory management.