Your bottom line lives and dies by how well you handle your inventory. When you nail your inventory management strategy, everything improves—from healthier profits to smoother operations and happier customers. The businesses that truly excel at stock control aren’t just saving money; they’re creating genuine competitive edges by keeping less cash trapped in warehouse shelves, preventing those dreaded “out of stock” conversations, and maintaining healthier bank balances.

Looking for the right way to manage your inventory? You’re in the right place. We’ve mapped out all the inventory management types you might consider—covering everything from clipboard-and-pen approaches that have stood the test of time to the latest cloud-based systems that track everything automatically. By the time you finish reading, you’ll know exactly which method makes sense for your particular business challenges.

Understanding Inventory Management Systems

Inventory management encompasses all the processes businesses use to track stock levels, monitor product movement, and maintain optimal inventory quantities. Good systems prevent overstocking (which ties up capital) and understocking (which creates lost sales opportunities).

The Two Main Types of Inventory Systems

Most inventory management approaches fall into one of two fundamental categories:

- Perpetual Inventory Systems track stock continuously as items move in and out. Every transaction updates inventory records immediately, providing real-time visibility. Modern Online Inventory Management Systems typically use perpetual tracking with technologies like RFID Asset Tracking or barcode scanning for precision.

- Periodic Inventory Systems rely on physical counts conducted at scheduled intervals – weekly, monthly, or quarterly. Between counts, businesses estimate inventory levels based on recorded transactions. Though less resource-intensive to implement, periodic systems sacrifice some accuracy compared to perpetual tracking.

The classification of inventory management extends beyond these two main systems into various specialised methodologies suited to different business models and industries.

Traditional Inventory Management Methods

Several classic inventory management methods form the foundation of effective stock control, even in today’s digital business environment.

Economic Order Quantity (EOQ)

EOQ uses mathematical formulas to calculate the ideal order size that minimises total inventory costs. This type of inventory management technique balances ordering costs (processing, shipping, handling) against carrying costs (storage, insurance, obsolescence). EOQ works best for businesses with relatively stable demand patterns and consistent lead times.

ABC Analysis

This method prioritises inventory control efforts by categorising items according to their value:

- A items: High-value products (roughly 20% of items representing 80% of value)

- B items: Medium-value products (about 30% of items representing 15% of value)

- C items: Low-value products (approximately 50% of items representing just 5% of value)

This inventory management method lets businesses focus resources on closely managing their most valuable stock while applying lighter controls to lower-value items.

FIFO and LIFO Methods

These types of stock control systems determine both physical handling priorities and accounting valuations:

- FIFO (First-In-First-Out): Assumes oldest inventory items sell first

- LIFO (Last-In-First-Out): Assumes the newest inventory items sell first

Beyond physical stock rotation, these methods significantly impact financial reporting, tax obligations, and profitability measurements, especially during periods of price volatility.

Safety Stock Management

Safety stock serves as a buffer against unexpected demand spikes or supply chain disruptions. Calculating optimal safety stock levels requires balancing stockout risks against excess inventory costs. Many businesses determine safety stock quantities by analysing historical demand patterns, lead time variability, and desired service levels.

Modern Inventory Management Techniques

Contemporary business challenges have spawned innovative inventory management techniques focused on maximising efficiency and responsiveness.

Just-in-Time (JIT) Inventory

JIT philosophy aims to minimise inventory by receiving goods only when needed for production or sales. This type of inventory management substantially reduces carrying costs and storage requirements but demands exceptional supplier coordination and accurate forecasting. Companies like Toyota pioneered JIT practices to eliminate waste throughout their manufacturing operations.

Vendor-Managed Inventory (VMI)

VMI flips traditional purchasing by making suppliers responsible for maintaining optimal inventory levels at their customers’ locations. The vendor monitors stock levels and handles replenishment decisions, creating a collaborative relationship that reduces administrative burdens while improving product availability. This arrangement works particularly well for established supplier relationships with consistent product demand.

Cross-Docking

Cross-docking virtually eliminates warehousing by transferring products directly from incoming shipments to outbound vehicles. Items spend minimal time at the distribution centre – sometimes just hours – before continuing to their final destination. This inventory management technique shines with predictable demand patterns, especially for perishable goods or promotional items.

Lean Inventory Management

Lean methodology focuses on eliminating seven core types of waste, including excess inventory itself. By implementing pull-based systems, optimising product flows, and continuously improving processes, businesses minimise unnecessary stock while maintaining service levels. Lean principles complement many other inventory management types by providing a waste-elimination framework.

Technology-Driven Inventory Systems

Digital technologies have transformed inventory management systems, offering unprecedented accuracy, efficiency, and analytics capabilities.

Barcode-Based Inventory Management

Barcode systems form the backbone of modern inventory tracking. By scanning product codes during receiving, movement, and sales, businesses create digital records of every transaction with minimal manual intervention. When connected to inventory software, barcode systems dramatically reduce data entry errors while providing real-time stock visibility.

RFID Asset Tracking

RFID Asset Tracking elevates inventory control through radio frequency identification tags that don’t require direct line-of-sight scanning. RFID enables batch reading of multiple items simultaneously, automated inventory counts, and improved supply chain visibility. The itemit asset tracking solution leverages RFID technology alongside other tracking methods for comprehensive inventory management.

Cloud-Based Inventory Management Software

Cloud-based types of inventory management software provide powerful capabilities without hefty IT infrastructure investments. These systems deliver:

- Multi-location inventory visibility

- Rule-based automatic reordering

- Demand forecasting and planning tools

- Integration with e-commerce, accounting, and shipping platforms

- Mobile access from anywhere with internet connectivity

From small business applications to enterprise platforms, these systems make sophisticated inventory control accessible for organisations of all sizes.

IoT and Automated Solutions

Internet of Things (IoT) devices create inventory systems that monitor themselves. Smart shelves detect product weight changes, automated guided vehicles move stock without human intervention, and connected sensors track environmental conditions for sensitive items. These technologies form the foundation of highly automated inventory management systems that minimise labour while maximising accuracy.

Selecting the Right Inventory Management Approach

Choosing among different inventory systems requires methodical evaluation of your business’s unique characteristics. The wrong system can create costly inefficiencies, while the right one becomes a competitive advantage. Let’s examine the critical factors that should guide your decision:

Business Size and Industry Considerations

Your operation’s scale and industry dramatically affect which inventory management type will deliver optimal results:

Small Businesses (Under $5M Annual Revenue)

- Look for cloud-based solutions with minimal upfront costs

- Prioritise ease of use and quick implementation

- Consider systems that grow alongside your business

- Focus on core features without paying for enterprise complexity

Medium Businesses ($5M-$50M)

- Seek solutions with robust reporting capabilities

- Evaluate integration options with existing business systems

- Balance comprehensive features with implementation complexity

- Consider industry-specific solutions that address unique challenges

Enterprise Organisations ($ 50M+)

- Evaluate systems that handle multi-location complexities

- Look for advanced analytics and forecasting capabilities

- Assess global deployment options and multi-currency support

- Consider customisation capabilities and API flexibility

Industry-Specific Requirements

- Retail operations need POS integration, multi-channel inventory synchronisation, and seasonal forecasting tools.

- Manufacturing businesses require production planning integration, component-level tracking, and bill-of-materials management.

- Wholesale distributors benefit from advanced warehouse management, lot/batch tracking, and logistics integration.

- Food/beverage companies need expiration tracking, FIFO enforcement, and temperature monitoring capabilities.

- Healthcare providers require compliance features, sterile supply management, and equipment maintenance tracking.

- Construction firms benefit from project-based inventory allocation and mobile tracking for field operations.

Key Assessment Criteria

When evaluating types of inventory management systems, score potential solutions against these essential criteria:

Functional Requirements (What you need the system to do)

- Inventory visibility – How comprehensively can you view stock across locations?

- Tracking granularity – Can you track by serial number, lot, batch, or expiration date if needed?

- Reporting capabilities – Does the system provide the analytics you need for decision-making?

- Mobile functionality – Can warehouse staff efficiently use the system on mobile devices?

- Automation options – What manual processes can the system eliminate?

- Growth compatibility – Will the system accommodate 3x or 5x your current volume?

Technical Requirements (How the system works)

- Integration capabilities – Does it connect with your accounting, e-commerce, shipping, and other systems?

- Data security – What protections are in place for your sensitive inventory data?

- Customisation options – Can the system adapt to your unique workflows?

- Offline functionality – Will the system work during internet outages?

- Backup procedures – How is your data protected against loss?

- API availability – Can you build custom connections to other systems?

Implementation Considerations

Successfully transitioning to a new inventory management system requires careful planning:

Preparation Phase

- Document current workflows and pain points with specific metrics

- Establish clear objectives with measurable success criteria

- Create a detailed data migration plan for product information, stock levels, and historical data

- Identify internal champions who will support the change

Rollout Strategy

- Consider pilot implementation in one department or location before full deployment

- Create contingency plans for potential disruptions during transition

- Schedule implementation during your business’s slower periods

- Develop a training program tailored to different user roles

Change Management

- Communicate benefits to all stakeholders to overcome resistance

- Provide hands-on training with real-world scenarios

- Establish a feedback loop for system improvements

- Create easily accessible documentation for common procedures

Comprehensive Cost Analysis

When evaluating types of inventory management systems, look beyond the sticker price:

Direct Costs

- Software license or subscription fees (per user/location)

- Hardware requirements (barcode scanners, asset tags, RFID readers)

- Implementation services and customisation

- Data migration and cleanup expenses

- Training costs for initial and ongoing education

- IT infrastructure upgrades, if needed

Return on Investment Factors

- Inventory carrying cost reduction (typically 15-30% with proper systems)

- Labour efficiency improvements (often 20-40% reduction in counting/handling time)

- Stockout reduction (can increase sales by 1-5%)

- Shrinkage and loss prevention (often 20-40% reduction)

- Order accuracy improvement (reducing returns and customer service costs)

- Data visibility for strategic decision-making

Hidden Costs to Consider

- Integration maintenance when other systems change

- Periodic version upgrades

- Staff turnover requires additional training

- Opportunity costs during implementation

- Potential business disruption during transition

By methodically evaluating these factors, you’ll identify which type of inventory system aligns with your business operations, industry requirements, and growth objectives. The right choice balances your immediate needs with long-term scalability while delivering measurable ROI.

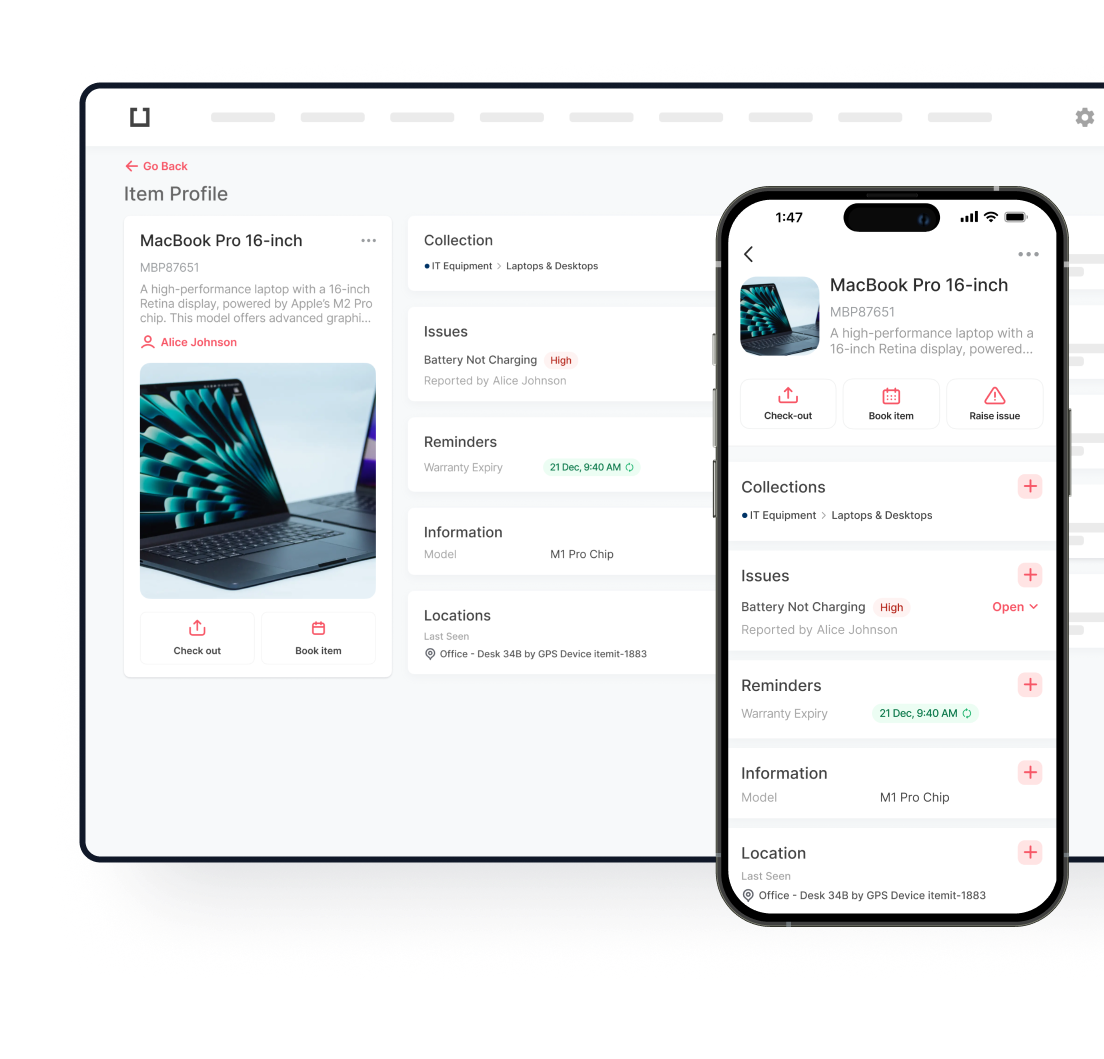

Implementing Inventory Management with itemit

The itemit asset tracking solution combines proven inventory methodologies with modern technology to create flexible, powerful stock control.

Comprehensive Tracking Solutions

itemit’s platform supports multiple identification technologies – including barcodes, QR codes, and RFID Asset Tracking – giving you flexibility to choose the right tracking method for different inventory categories. This hybrid approach allows businesses to implement optimal tracking based on item value, movement frequency, and physical characteristics.

Seamless System Integration

As a cloud-based Online Inventory Management System, itemit connects seamlessly with your existing business software. This integration eliminates data silos, automatically synchronises inventory information across systems, and provides complete visibility throughout your operation.

Scalable for Businesses of All Sizes

Whether you manage inventory for a single location or coordinate stock across multiple facilities, itemit scales to match your requirements. The system grows alongside your business, adding capabilities as your inventory management needs evolve.

Real-World Success Stories

Diverse businesses have transformed their inventory operations using itemit:

- A manufacturer reduced stock-outs by 78% while decreasing overall inventory value by 15%

- A retail chain achieved 99.8% inventory accuracy using RFID Asset Tracking, dramatically reducing shrinkage

- A healthcare provider tracked valuable medical equipment with asset tags, improving utilisation rates and patient care

Your Path to Inventory Excellence

The right type of inventory management system does more than track stock—it optimises your entire supply chain. Whether you choose traditional methods, modern techniques, or a combination approach, effective inventory control gives you the visibility and efficiency needed to satisfy customers while controlling costs.

Consider your business’s unique requirements when selecting among inventory management methods. Factor in your industry, growth plans, staff capabilities, and existing systems to find the perfect fit.

Ready to upgrade your inventory management? Contact itemit today to discover how our asset tracking solution can streamline your inventory operations and boost your bottom line.

Try itemit

Choose a better way to track

your assets.

Start your free 14-day trial now!

Keep Learning

itemit Blog

Tips, guides, industry best practices, and news.

The Ultimate Guide to RFID Inventory Management

Discover the beginner’s guide to RFID inventory management technology. Learn how to improve accuracy, streamline stock tracking, and boost efficiency today!

Understanding the Inventory Tracking Process and Its Importance

Learn about the inventory tracking process and its importance. Discover how it helps improve efficiency, accuracy, and overall business management.

How to Choose the Right Inventory Scanner for Your Business

Use our guide to choose the right inventory scanner for your business. Learn which features matter, compare types, and get tips for selecting the best fit.