Any workplace must ensure that equipment is safe and works well. A big part of this is the PUWER equipment regulations, officially called the Provision and Use of Work Equipment Regulations. These rules aim to lower the risks associated with using equipment by telling employers how to manage and fix it. By following PUWER equipment guidelines, businesses can make the workplace safer and keep their workers from getting hurt.

Equipment management under PUWER is all about taking care of things. It makes sure that employers check their tools to make sure they are useful, keep them in good shape, and train their employees properly. Following PUWER equipment standards is very important to keep accidents from happening and to follow safety laws at work, whether it’s with tools in a factory or on a construction site.

Equipment management is important for more reasons than just following the law. As a result, there is more safety, less downtime due to broken equipment, and more work gets done. Any organisation that wants to keep its operations safe and efficient needs to know what the PUWER equipment regulations cover.

What Equipment Is Covered by PUWER?

When you walk into a busy warehouse or factory floor, how often do you stop to think about whether the tools and machinery around you are safe and well-kept? To make sure compliance and safety at work, you need to know what equipment is covered by PUWER. The rules cover a lot of different types of tools and machines used in many different fields. They cover manufacturing equipment, construction tools, and even mobile work vehicles. PUWER makes sure that this kind of equipment is safe to use, well-kept, and right for the job. Businesses can find potential problems before they get worse by following regular inspections and procedures. This cuts down on downtime and accidents that could affect daily operations.

Think about the machines and tools you use at work. Do they meet PUWER’s safety standards? Equipment that PUWER covers includes machines, hand tools, lifting gear, and mobile work gear. This makes sure that these important things are safe and do their job. Of course, there are some exceptions. Some things that aren’t covered by PUWER are private vehicles and home appliances. This is because these aren’t usually used at work and don’t pose the same risks as equipment used at work. PUWER’s main job is to make sure that the risks that come with the tools and machines that workers use every day are managed. Also, some equipment is governed by more specific laws. For example, pressure systems and explosive materials are governed by separate laws.

PUWER Equipment List

Reducing risks and guaranteeing compliance rely upon realising the kind of tools PUWER covers. Every category stands for possible risks that, if not under control, could cause legal obligations and workplace mishaps. Usually covered under PUWER rules, these are the main types of equipment:

- Machinery: This covers industrial machinery used in several fields, including manufacturing lines, assembly robots, conveyor belts, and cutting tools. The main focus is on keeping these complicated systems safe and well-maintained to avoid mishaps and downtime.

- Hand Tools: Basic daily tools include wrenches, screwdrivers, saws, and drills. Though they seem less dangerous, improper use or inadequate maintenance can still result in injuries.

- Lifting Equipment: Any tool used to safely move large objects—such as cranes, forklifts, hoists, and lifting slings. Preventing load-related mishaps depends on routinely ensuring these are checked.

- Mobile Work Equipment: This covers tractors, bulldozers, or even ride-on mowers—vehicles and tools used for tasks connected to the workplace. Because of their mobility and need for particular safety procedures, these create special hazards.

- Personal Protective Equipment (PPE) Used in Machinery Operation: Although not always considered, PPE, such as helmets, gloves, and protective eyewear, is crucial for safely operating machinery and falls under more general PUWER-related responsibilities.

Main Requirements of PUWER in Respect of Equipment Provided for Use at Work

Workplace equipment can really be a great help or a big problem, all depending on how it’s handled. PUWER regulations mainly focus on making sure that equipment not only works properly but also ensures everyone’s safety. Let’s dive into what employers should keep in mind — we’ll take a practical look at the real-world risks and the solutions that can help.

Suitability of Equipment

Imagine a worker asked to cut metal sheets with a tool meant for wood. That mismatched is dangerous as well as ineffective. PUWER places responsibility on companies to provide the correct tools for the job—those that fit the task, the surroundings, and the operator’s skill level. Still, it’s more than just following a formula. It is about realising that inappropriate tools cause errors, injuries, and expensive downtime. When evaluating fit, go beyond mere functionality and take into account factors including temperature, noise, and even user tiredness.

Regular Maintenance and Inspections

Equipment breaks not out of nowhere. It gradually wears down, a frayed wire here, a loose bolt there; one day, it breaks down completely. PUWER forces companies to have a proactive maintenance schedule in place to find these problems early on. Consider it as a machinery health check. Regular inspections offer an opportunity to identify possible hazards before they become full-fledged issues. Thus, they should be more than a formality. Employers should record these checks so that any repairs are done and a clear record of maintenance actions exists.

Operator Training and Competence

Have you ever seen someone have trouble with a machine they’ve never used before? Being able to watch it is scary and dangerous. PUWER rules make it clear that operators need to be trained over and over again. It is not enough to just teach people “how to do” something. It should also include being able to spot early signs of a problem and knowing what the equipment can and can’t do. Employers should also make sure that the training fits the needs of each worker. When employees have different amounts of experience and responsibility, a one-size-fits-all approach won’t work.

Safety Features and Proper Use

Safety measures aren’t just for show — they really can save lives. Emergency stop buttons, protective guards, and warning signals are super important for making sure we follow PUWER regulations. But here’s the thing: they have to be functional and used the right way. It’s really important for employers to make sure that safety features are never skipped or taken away just to save a bit of time. It’s really key to ensure that these features are simple to find and easy to grasp. An easy-to-find emergency stop button can really change the game in a tough situation.

If you want to know more—check our PUWER Regulations Guide, where we compile all critical details for A to Z.

How Often Is Equipment Checked Under PUWER?

Maintaining the safety and functionality of workplace equipment is not one-time job. Although the PUWER rules call for continuous inspections and checks, the frequency of these events will rely on several factors. Let’s examine the factors influencing inspection frequency and the reasons behind their relevance for preserving a safe workplace.

Inspection Frequency Requirements

Regarding how often equipment should be examined under PUWER, there is no universal rule. The type of equipment, how it is used, and the conditions it operates in determine the frequency. For example:

- High-risk machinery: Because of the possibility of major mishaps, machinery, including cranes, forklifts, and lifting gear, requires more regular maintenance.

- Frequently used tools: Constant use of hand tools or machinery should be routinely inspected to find any wear and tear before it causes a breakdown.

- Specialised equipment: Items used in hazardous surroundings, such as chemical plants or building sites, demand more thorough inspection plans to consider demanding working conditions.

One hopes to avoid mishaps by spotting possible problems before they cause damage. Therefore, you absolutely must have an inspection calendar tailored to your workplace’s particular hazards.

Factors That Influence Inspection Frequency

The frequency of inspections under PUWER isn’t random — it’s based on practical considerations, such as:

- Equipment type: Different hazards associated with heavy machinery mean different inspection needs than with hand tools.

- Usage levels: An equipment piece will wear down more quickly the more often it is used. Equipment used heavily calls for more regular inspections.

- Workplace conditions: Regular inspections are especially important since environmental elements like dust, moisture, or extreme temperatures can hasten equipment wear and tear.

PUWER Equipment Requirements: Ensuring Compliance

Making sure workplace equipment is safe isn’t a one-and-done deal. It’s a continuous thing where employers need to be on their toes and take action to manage risks. Let’s dive into the practical side of meeting PUWER requirements — no-nonsense, just straightforward tips to help you make compliance a regular part of your day.

Key PUWER Requirements for Equipment Compliance

- Get the Right Gear for the Task: It’s pretty obvious, isn’t it? Your team needs the right tools for the job they’re tackling. Giving someone the wrong tool for the job is just asking for problems. No matter if it’s big machines or simple tools, the gear has to fit the job and the folks using it.

- Keep Your Equipment in Good Shape: Things break. It’s inevitable. That’s why PUWER emphasises regular maintenance and inspections. But don’t just think of these checks as a chore — they’re a chance to spot potential problems before they cause real damage. Create a maintenance plan that fits the way your equipment is used. High-use tools? Check them more often. Got gear that sits idle? It might need less frequent attention.

- Make Sure Operators Know What They’re Doing: It’s like, you wouldn’t hand over the keys to your car without making sure someone knows how to drive, right? So why let someone mess around with equipment they haven’t been trained to use? PUWER really focuses on making sure everyone knows their stuff.

- Make Sure the Safety Features are All Set Up: Safety guards, emergency stop buttons, and warning systems are must-haves, not just nice-to-haves. They’re just out there saving lives. They only do their thing if they’re in good shape and used the right way. Just make sure your team gets why these features are important, and don’t skip over them just to finish up quickly.

Practical Steps to Stay Compliant

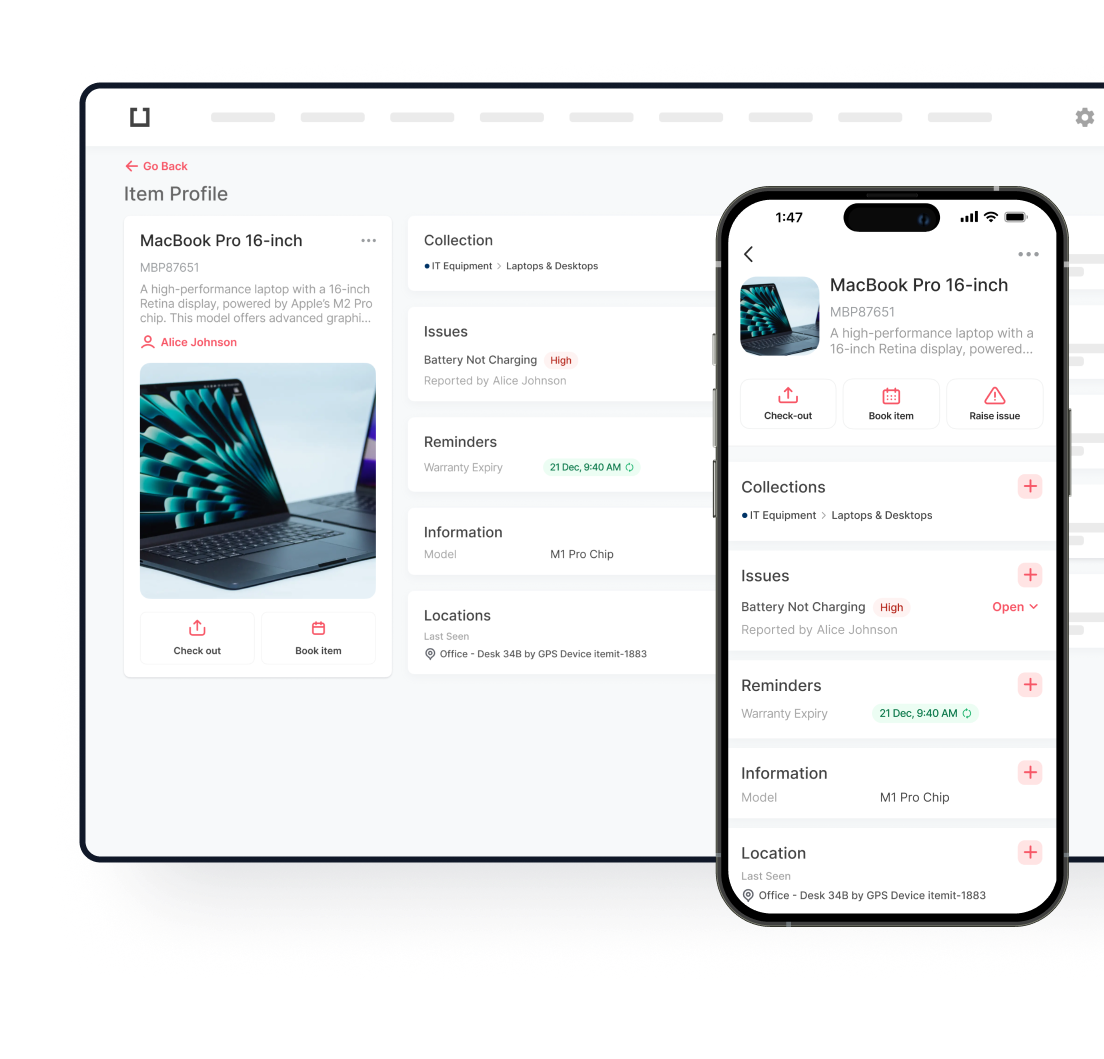

Use an Asset Tracking System to Stay Organised

It’s easy to overlook inspections and maintenance plans, particularly when there is a lot of equipment. An asset tracking system will enable you to monitor everything, from the moment a tool was last checked to when it is due for maintenance. This is a sensible approach to guaranteeing nothing gets overlooked.

Keep Records That Matter

Forget about paperwork for paperwork’s sake. Your records should have a purpose — to show that you’re staying on top of PUWER requirements. Keep logs of inspections, repairs, training sessions, and any safety incidents. These records aren’t just for audits; they’re your proof that you’re taking safety seriously.

Don’t Skip Risk Assessments

Risk assessments aren’t just about filling out forms. They’re about spotting issues before they become problems. Make them a regular part of your safety process, and use them to tweak your maintenance and training plans. The goal? Fewer surprises and a safer workplace.

Involve Your Team in Safety

Safety isn’t just a task for your team; it’s a shared journey we take together! Let’s inspire your staff to share their thoughts on equipment issues and suggest improvements. When each person feels valued in maintaining safety, it becomes second nature for everyone to follow suit!

Including these actions in your daily schedule will enable you to meet PUWER criteria without simply adhering to the rules. You will also create a workplace in which people feel safe, appreciated, and free to give their all.

Try itemit

Choose a better way to track your assets. Start your free 14-day trial now!

Keep Learning

itemit Blog

Tips, guides, industry best practices, and news.

Benefits of Vendor Managed Inventory for Your Business

[lwp_divi_breadcrumbs font_icon="5||divi||400"...

The Key to Asset Reliability: Preventive Maintenance and Real-Time Tracking

Enhance asset reliability with preventive maintenance and real-time tracking. Reduce downtime, improve efficiency, and extend asset lifespan with smart strategies.

Optimising Asset Performance Management: Strategies for Maximum Efficiency

Explore practical strategies to optimise asset performance management, maximise efficiency, and enhance productivity with predictive and real-time monitoring tools.