Construction projects hemorrhage money. Global losses exceed $1.2 trillion each year when risk management falls short. Building sites now face intricate challenges – from safety hazards to supply chain chaos. Old-school reactive methods can’t handle today’s project complexity. New technologies and smart planning give construction companies serious advantages. Good risk management turns disasters into minor speed bumps.

Key Takeaways

- Early risk identification significantly reduces project costs through preventive measures and planning

- Technology integration dramatically decreases safety incidents with real-time monitoring systems

- Equipment tracking prevents substantial project delays through predictive maintenance protocols

- Proactive communication eliminates most stakeholder conflicts via structured frameworks

- Digital monitoring systems catch developing issues much faster than manual inspection methods

- Predictive maintenance considerably extends equipment lifespan while reducing unexpected breakdowns

Why Does Early Risk Identification Make or Break Construction Projects?

Smart money gets spent before ground breaks. Projects that dig deep into risk identification during planning show dramatically better results. The construction risk management process kicks off by spotting threats before they explode into budget-busting nightmares.

Understanding the Five Critical Risk Categories

Construction jobs get hit from multiple directions. Safety risks? Worker accidents, equipment going haywire, dangerous site conditions. Financial risks bring budget disasters, cash flow headaches, supplier payment meltdowns. Environmental risks throw curveballs – nasty weather, ground problems, regulation changes. Legal risks spawn contract battles, compliance failures, liability nightmares. Operational risks create scheduling chaos, resource shortages, quality disasters.

Each type needs different handling. Safety risks pack the biggest punch – construction sites see injury rates 50% higher than other industries. Financial problems cascade like dominoes, where one budget issue triggers multiple downstream disasters.

Pre-Construction Assessment Strategies

Top-performing project teams run intensive brainstorming sessions with all key players. These collaborative meetings uncover potential problems from different angles, tapping into varied expertise. Site analysis reveals physical challenges – unstable ground, environmental hazards, access nightmares. Regulatory reviews prevent expensive violations and permit delays.

Looking at past projects provides goldmine insights into recurring risk patterns. Teams that document lessons learned build knowledge banks that sharpen future risk identification. Asset Tracking Software delivers project oversight by tracking equipment, materials, and site conditions throughout the entire job.

Building a construction safety management system during planning creates frameworks for ongoing risk watching. These systems weave safety protocols, reporting procedures, and response plans into daily work.

How Can Technology Transform Your Construction Safety Management System?

Digital revolution changes everything about construction safety management. Modern construction technology kicks outdated manual processes to the curb with automated, data-driven solutions. These tools provide unmatched visibility into site conditions and worker safety numbers.

IoT Sensors and Real-Time Hazard Detection

Internet of Things devices create thinking construction sites that continuously watch environmental conditions. Air quality sensors catch dangerous gases, dust particles, and airborne hazards threatening worker health. Temperature and humidity systems prevent heat-related sickness during brutal weather. Noise monitors keep sites compliant with safety standards and local rules.

Common IoT Monitoring Applications:

- Gas leak detection with automatic ventilation system activation

- Structural vibration monitoring for heavy equipment operations

- Wind speed measurement for crane operation safety

- Ground stability sensors preventing cave-ins and collapses

- Radiation detection in renovation and demolition projects

IoT in construction setups blast instant alerts when dangerous conditions develop. Automated systems shut down equipment, activate safety protocols, or clear areas without human input. Real-time data transmission gets supervisors immediate notification of emerging hazards.

Wearable Technology for Worker Protection

Smart wearables turn basic protective equipment into active safety monitoring systems. Heart rate monitors catch physical distress, exhaustion, or medical emergencies before workers drop. Fall detection devices automatically trigger emergency responses when accidents happen. GPS tracking enables rapid location and rescue of injured personnel.

Advanced wearables watch worker fatigue levels, stopping accidents caused by exhaustion or poor judgment. Some devices detect proximity to dangerous equipment or off-limits areas, giving audio warnings to prevent accidents. Integration with site communication systems enables instant coordination between workers, supervisors, and emergency responders.

Construction Equipment Tracking boosts safety compliance by monitoring equipment maintenance status, operator certifications, and usage patterns affecting safety performance.

What Role Does Equipment Management Play in Risk Reduction?

Equipment failures wreck construction schedules and budgets. Unplanned downtime hammers construction companies with average costs of $50,000 per day on large projects. Smart equipment management cuts these risks through predictive maintenance, real-time monitoring, and optimized usage.

Predictive Maintenance Through Smart Monitoring

Sensor-equipped machinery feeds continuous performance data that spots developing problems weeks before catastrophic failures. Vibration analysis catches bearing wear, misalignment, and mechanical issues early. Temperature monitoring identifies overheating problems damaging engines and hydraulic systems. Fluid sensors track oil quality, hydraulic pressure, and coolant conditions.

Key Predictive Maintenance Benefits:

- 25-30% reduction in maintenance costs through planned repairs

- 35-45% decrease in equipment downtime periods

- 20-25% extension of equipment lifespan

- 50-70% reduction in catastrophic failure incidents

- 15-20% improvement in fuel efficiency and performance

Machine learning algorithms crunch historical performance data to predict optimal maintenance schedules. These systems consider usage patterns, environmental conditions, and manufacturer recommendations for customized maintenance plans. Automated work orders give technicians advance notice of required services.

Real-Time Asset Tracking and Utilization

GPS and RFID technologies deliver precise location data for all equipment across multiple job sites. Asset tracking systems stop theft, cut search time, and optimize equipment allocation between projects. Geofencing alerts managers when equipment leaves authorized areas or operates outside scheduled hours.

Usage monitoring reveals underutilized equipment that could serve other projects, boosting return on investment. Detailed reports identify patterns affecting equipment performance and maintenance needs. Integration with project scheduling systems keeps equipment availability aligned with construction timelines.

Track Heavy Construction equipment across multiple sites enables centralized fleet management maximizing utilization while cutting risks. Companies can Increase Construction Equipment’s Lifespan through proper tracking, maintenance scheduling, and usage optimization.

Construction technology solutions merge equipment data with project management systems, delivering complete visibility into asset performance and availability. This construction risk management approach prevents delays caused by equipment shortages or unexpected failures.

How Do You Build a Proactive Communication Framework for Risk Management?

Good communication turns risk management from individual responsibility into team effort. Structured communication frameworks push critical information efficiently between all project stakeholders, stopping risks from growing into serious problems.

Creating Risk-Aware Culture Across Teams

Building risk awareness demands training programs that educate all personnel about potential hazards and proper response procedures. Regular safety meetings reinforce risk consciousness and create forums for discussing emerging concerns. Incident reporting systems encourage workers to identify and report potential problems without punishment fears.

Leadership commitment shows risk management importance throughout the organization. When supervisors actively participate in risk discussions and respond quickly to concerns, workers engage more in risk identification activities. Recognition programs reward employees who identify risks or suggest improvements.

Clear accountability structures define responsibilities for risk monitoring and mitigation. Each team member understands their role in the overall risk management framework. Regular performance reviews include risk management metrics, reinforcing proactive risk identification importance.

Digital Collaboration for Stakeholder Alignment

Cloud-based project management platforms create centralized communication hubs where all stakeholders access current risk information. Real-time updates keep everyone working with accurate, up-to-date data about project risks and mitigation efforts. Mobile applications enable field personnel to report risks immediately as they develop.

Structured meeting formats maximize risk review session effectiveness. Weekly risk meetings follow consistent agendas covering current risks, mitigation progress, and emerging concerns. Documentation standards ensure important decisions and action items get proper recording and follow-up.

IoT in construction systems integrate with communication platforms, delivering automated risk notifications and status updates. These integrations cut manual reporting requirements while keeping stakeholders informed about developing risks.

What Financial Strategies Minimize Construction Project Risks?

Financial risks attack project viability through budget overruns, cash flow problems, and unexpected cost spikes. Smart financial risk management protects projects against these threats through careful planning, monitoring, and adaptive strategies.

Supply chain diversification cuts risks tied to single-source dependencies. Multiple suppliers for critical materials prevent delays when individual suppliers hit problems. Long-term contracts with key suppliers deliver cost stability and guaranteed availability during market swings.

Cash flow forecasting predicts funding requirements throughout project lifecycles. These projections spot potential shortfalls early, enabling proactive financing arrangements. Regular budget reviews compare actual spending against projections, highlighting areas needing attention.

Insurance strategies transfer appropriate risks to specialized carriers while keeping reasonable premium costs. Broad coverage protects against major losses while deductible structures encourage effective loss prevention activities. Claims management procedures guarantee rapid response when covered incidents occur.

This construction risk management approach protects project financial health while maintaining operational flexibility. Digital financial monitoring systems deliver real-time visibility into project financial performance and risk indicators.

How Can Continuous Monitoring Systems Prevent Small Issues from Becoming Major Problems?

Continuous monitoring flips reactive problem-solving into proactive issue prevention. Real-time systems catch developing problems early when corrective action stays cost-effective and minimally disruptive.

Project dashboards consolidate key performance indicators into visual displays highlighting developing risks. These systems track schedule progress, budget performance, safety metrics, and quality indicators. Automated alerts notify managers when metrics exceed predetermined thresholds, triggering immediate investigation and response.

Essential Monitoring Metrics:

- Schedule adherence and critical path progress

- Budget variance and cash flow projections

- Safety incident rates and near-miss frequencies

- Equipment utilization and maintenance compliance

- Material delivery schedules and inventory levels

- Weather conditions and environmental factors

- Regulatory compliance and inspection results

Performance trend analysis spots patterns indicating developing problems. Gradual deterioration in any metric signals need for intervention before acute problems develop. Historical data comparison helps teams recognize recurring issues and implement preventive measures.

Regular plan updates incorporate lessons learned from ongoing monitoring activities. Adaptive management approaches modify strategies based on actual project performance and changing conditions. Continuous improvement processes refine monitoring systems and response procedures.

Construction technology platforms merge multiple data sources into unified monitoring systems. These solutions deliver complete project visibility while cutting administrative overhead tied to manual monitoring activities.

Your Next Steps

Modern construction risk management needs proactive strategies leveraging technology, communication, and systematic planning. Companies investing in thorough risk management systems achieve superior project outcomes with lower costs, faster completion times, and better safety performance. IoT devices, predictive analytics, and real-time monitoring create unprecedented visibility into project risks and performance.

Success depends on commitment to early risk identification, technology adoption, and continuous improvement processes. Organizations embracing these advanced approaches position themselves for sustained competitive advantage in an increasingly complex construction environment. The future belongs to companies turning risk management from reactive problem-solving into proactive opportunity creation.

Smart construction risk management strategies protect projects while enabling growth and innovation. Teams implementing these proven approaches build stronger relationships with clients, reduce insurance costs, and achieve more predictable project outcomes.

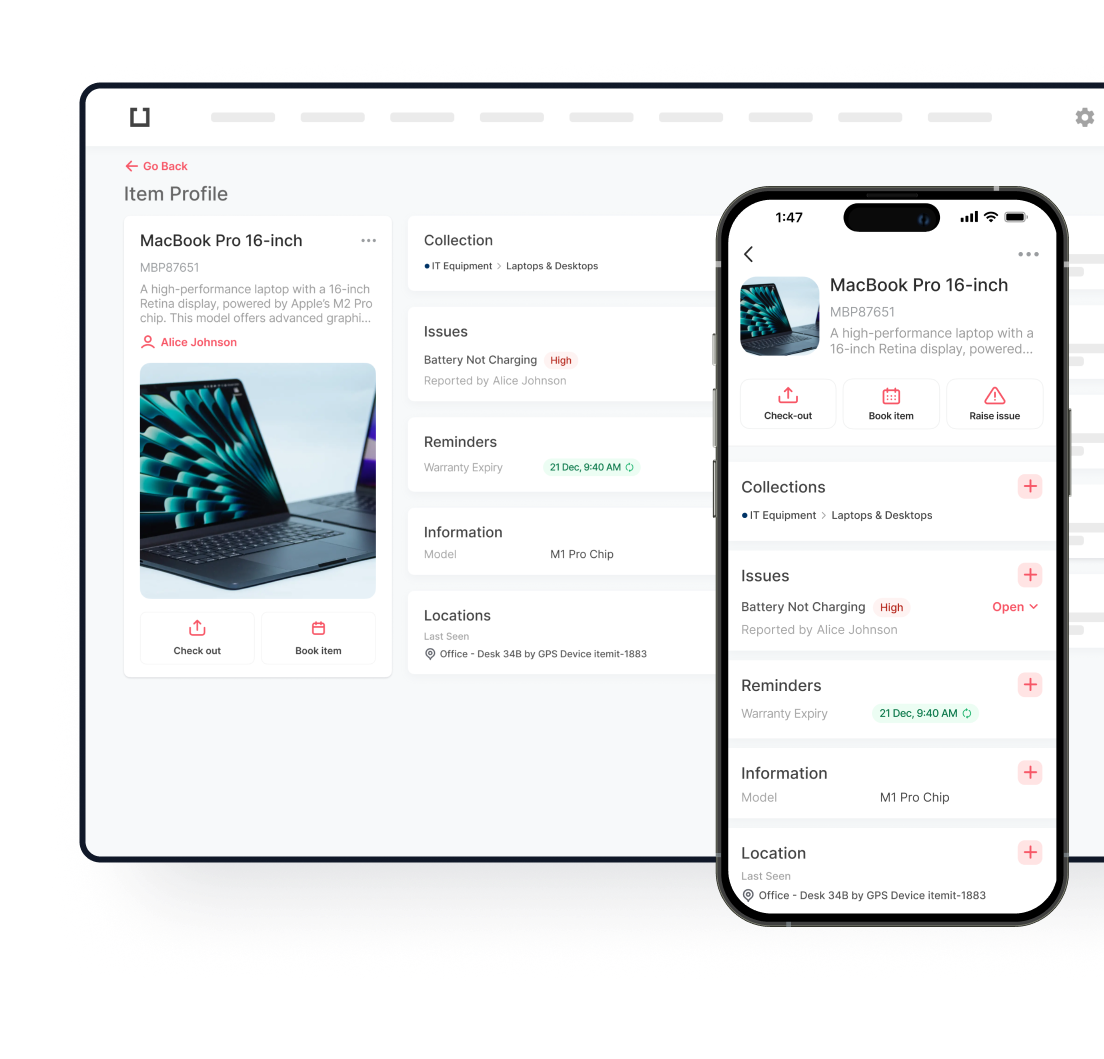

Try itemit

Choose a better way to track

your assets.

Start your free 14-day trial now!

Frequently Asked Questions

What percentage of construction costs should be allocated to risk management?

Typically 5-10% of project budget should cover risk management activities, including technology systems, insurance coverage, and contingency funds for unexpected issues.

How often should construction risk assessments be updated?

Risk assessments should be reviewed weekly during active construction phases and updated immediately when project scope, site conditions, or regulatory requirements change.

What's the ROI of investing in construction risk management technology?

Studies demonstrate 3:1 to 5:1 return on investment through reduced incidents, faster project completion times, lower insurance premiums, and decreased liability exposure.

Can small construction companies afford construction risk management systems?

Yes, cloud-based solutions now offer scalable options starting from $50-200 per month, making advanced risk management tools accessible to companies of all sizes.

What are the most common construction risks that cause project failures?

Weather delays (35%), equipment failures (28%), safety incidents (22%), and supply chain disruptions (15%) represent the leading causes of construction project problems.

Keep Learning

itemit Blog

Tips, guides, industry best practices, and news.

Key Strategies for Successful Construction Business Development

Smart strategies for construction business development that help attract clients, increase project success, and drive sustainable growth in a competitive market.

Optimising Construction Storage for Better Project Management

Essential construction storage methods that enhance site management, improve workflow efficiency, reduce material loss, and keep projects on schedule and budget.

Everything You Should Know About Material Management in Construction

Discover everything you need to know about material management in construction. Improve inventory control, reduce costs, and enhance project efficiency and quality.