Managing business assets has never been more challenging. With equipment scattered across multiple locations, valuable tools going missing, and maintenance schedules becoming increasingly complex, traditional tracking methods simply can’t keep up.

Many businesses still rely on spreadsheets and manual processes that were outdated a decade ago. The result? Lost equipment, missed maintenance windows, and countless hours wasted searching for items that should be instantly locatable.

This is where RFID asset tracking steps in as a practical solution that actually works in the real world.

Key Takeaways

- RFID technology enables automatic asset identification using radio frequency signals, eliminating manual scanning requirements and improving tracking accuracy

- Passive and active RFID tags offer different advantages with passive tags being cost-effective for short-range applications whilst active tags provide longer-range tracking for high-value assets

- Real-time visibility transforms asset management by providing instant location updates and comprehensive asset lifecycle monitoring

- Implementation requires strategic planning including proper tag placement, reader positioning, and integration with existing asset management systems

Understanding RFID Asset Tracking Technology

Think of RFID as giving every piece of equipment a voice that can communicate without any effort from your team. Unlike barcodes that need to be seen and scanned individually, RFID tags can be read through boxes, from across rooms, and even when they’re dirty or damaged.

The technology itself is straightforward. Small electronic tags get attached to your assets, and these tags contain unique digital information. When a reader device comes near these tags, they automatically share their stored data. It’s similar to how contactless payment cards work with card readers.

What makes this particularly useful for asset management is speed and accuracy. A single RFID reader can identify hundreds of tagged items in seconds, updating your records automatically. No more clipboard surveys or barcode hunting.

The mechanics are surprisingly simple for such powerful technology. RFID tags contain a tiny antenna and microchip that respond to radio signals from readers. When a reader sends out its signal, any tags within range wake up and transmit their information back.

This wireless communication happens instantly and doesn’t require perfect positioning like barcode scanning. Tags can even work through materials like cardboard, plastic, and fabric. This means inventory counts that used to take hours can now be completed in minutes.

Passive vs Active RFID

Not all RFID tags are created equal, and choosing the right type makes a significant difference to your tracking success.

Passive RFID Tags

Passive tags don’t have batteries. Instead, they draw power from the reader’s signal when it gets close enough. This design choice brings several real-world advantages that matter to busy operations.

These tags last for decades without any maintenance. Once attached to an asset, you can forget about them. They’re also much smaller than their active counterparts, making them easier to attach discreetly to equipment. At 10p to £2 per tag, they’re affordable enough for large-scale deployments.

The trade-off is range. Passive tags typically work within a few metres of the reader, making them perfect for warehouses, offices, and controlled environments where you can get reasonably close to your assets.

Active RFID Tags

Active tags carry their own battery pack, which allows them to broadcast signals much further. We’re talking distances of 100 metres or more, making them ideal for tracking vehicles, large machinery, or assets that move around expansive sites.

The battery also enables additional features like temperature sensors or GPS integration. However, this capability comes at a cost. Active tags typically cost £15-£50 each and need battery replacement every few years.

For high-value assets where knowing exact location is critical, the Benefits of RFID technology become immediately apparent. Construction companies tracking expensive machinery or hospitals monitoring critical equipment often find active tags pay for themselves quickly.

Advanced RFID Implementation

For businesses with mobile assets, combining RFID with GPS tracking creates something approaching the holy grail of asset management. You get pinpoint accuracy when assets are nearby, plus wide-area tracking when they’re on the move.

This hybrid approach works particularly well for construction companies, service businesses, and any operation that moves equipment between sites. The GPS component provides real-time location updates as assets travel, whilst RFID takes over for detailed tracking once they arrive at destinations.

The itemit system handles this integration seamlessly. Whether your assets are sitting in the warehouse or travelling to a job site three counties away, you maintain complete visibility. The system can even send alerts if assets go to unexpected locations or don’t arrive when scheduled.

Improving Inventory Accuracy Through RFID Implementation

Manual inventory processes are notoriously unreliable. People miss items, miscount quantities, and make data entry errors. Studies consistently show that businesses using manual methods typically achieve only 65% inventory accuracy.

RFID transforms this picture completely. Organizations implementing comprehensive RFID systems regularly achieve 95% accuracy or higher. The improvement comes from eliminating human error in the counting process whilst capturing data automatically as assets move through your facility.

Instead of quarterly inventory nightmares involving entire teams working overtime, RFID enables continuous, real-time inventory updates. Items are counted automatically as they pass checkpoints or get moved around your facility.

Effective RFID inventory management requires careful planning, but the payoff is substantial. Businesses report dramatic reductions in time spent on inventory processes, plus much better data for making purchasing and allocation decisions.

RFID Best Practices for Successful Implementation

Getting RFID right requires attention to some key details that separate successful deployments from expensive disappointments.

RFID readers need strategic placement to provide comprehensive coverage without creating dead zones or signal conflicts. The goal is ensuring every tagged asset can be reliably detected whilst avoiding interference between readers.

Entry and exit points are natural choices for reader placement, as they capture asset movements automatically. Overhead installations work well for wide-area coverage, whilst handheld readers provide flexibility for spot checks and detailed investigations.

Success with your RFID Best Practices depends heavily on getting the fundamentals right during initial setup. Taking time for proper planning prevents costly modifications and ensures your system works reliably from day one.

Setting Up Your RFID Tag Tracking System

Creating an effective RFID system starts with understanding what you’re trying to achieve and how the technology fits into your existing operations.

Initial System Assessment and Planning

Start by taking stock of your current asset management situation. What assets need tracking? Where are they located? How do they move through your operation? Understanding these basics shapes every other decision.

Consider your asset inventory scope, including the quantity, value, and criticality of items you need to track. Think about what information you need beyond just location. Do you need condition monitoring, usage patterns, or maintenance schedules?

Environmental conditions matter significantly. Indoor office environments are much simpler than outdoor construction sites or industrial facilities with heavy machinery and harsh conditions. Your environment influences tag selection, reader placement, and system design.

Hardware Selection and Procurement

Choose hardware that matches your actual requirements rather than buying the most sophisticated option available. The total cost includes tags, readers, infrastructure, and ongoing maintenance, so factor in everything.

Tag specifications should match your asset types and environmental conditions. Reader capabilities need to provide adequate coverage and performance for your specific situation. Antenna configurations should be optimized for your facility layout, and network infrastructure must support reliable data transmission.

A well-planned RFID tag tracking system provides the foundation for long-term success. Professional guidance during setup helps avoid common mistakes that can derail projects.

Small Business Applications and Benefits

RFID isn’t just for large corporations anymore. Smaller businesses are discovering that modern RFID systems can be implemented cost-effectively and scaled gradually as needs grow.

Cost-Effective Solutions for Smaller Operations

The key for smaller businesses is starting focused and expanding systematically. Begin with your most valuable or frequently misplaced assets. This approach controls initial costs whilst demonstrating clear value.

Small businesses often see particularly dramatic benefits. Reduced labour costs from automated tracking, improved asset utilisation through better visibility, enhanced customer service from accurate inventory information, and simplified compliance through automatic record-keeping all contribute to healthier bottom lines.

Scalable Growth and Expansion

RFID for Small Business implementations can start small and grow organically. The itemit platform specifically accommodates this approach with flexible pricing and expanding functionality as your needs develop.

What starts as basic location tracking can evolve into comprehensive asset lifecycle management as your business grows and your requirements become more sophisticated.

Integration with Asset Management Software

RFID reaches its full potential when it connects seamlessly with your broader business systems. Raw tracking data becomes actionable business intelligence that drives better decisions.

Data Synchronisation and Real-Time Updates

Good integration means RFID data flows automatically into your asset management system without manual intervention. This eliminates data silos and ensures everyone works from the same accurate information.

The benefits are immediate and ongoing. Automated data capture reduces manual entry requirements, real-time dashboards provide instant operational visibility, comprehensive reporting supports data-driven decision making, and alert systems notify users when attention is needed.

Workflow Optimisation and Process Improvement

Well-integrated systems don’t just track assets; they help optimize how you use them. By analyzing movement patterns and utilisation rates, you can identify inefficiencies and improvement opportunities.

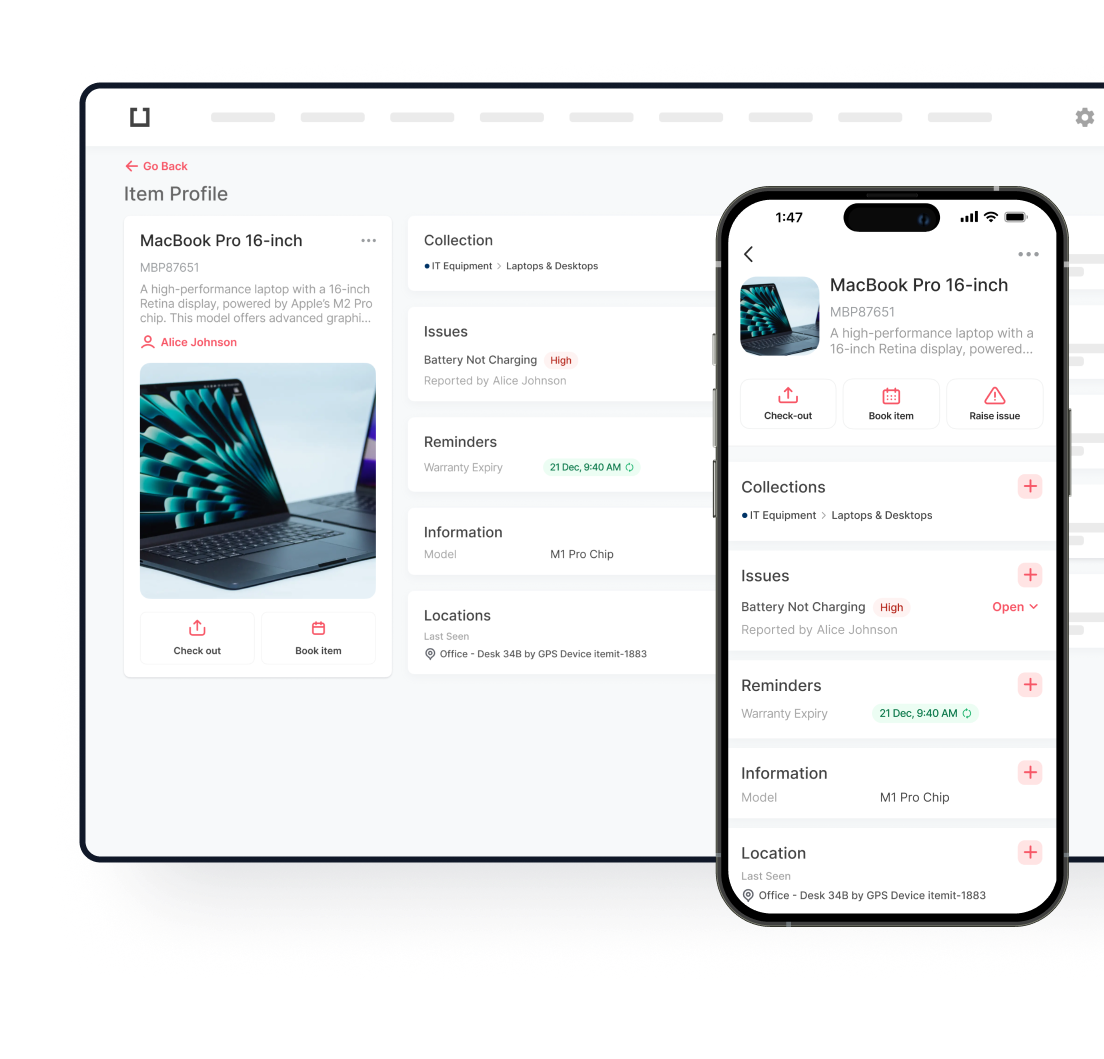

The itemit platform demonstrates effective integration by combining powerful tracking capabilities with straightforward daily operation. Users get comprehensive visibility without complexity that gets in the way of actual work

Measuring ROI and Implementation Success

RFID implementations should deliver measurable value through improved efficiency, reduced costs, and better asset utilisation. Understanding how to measure these benefits helps justify investment and identify areas for continued improvement.

Key Performance Indicators

Track the metrics that matter most to your operation. Asset utilisation rates show how effectively you’re deploying resources. Inventory accuracy improvements demonstrate system effectiveness. Time savings in asset location and inventory processes translate directly to labour cost reductions. Cost reductions from eliminated losses and improved efficiency flow straight to your bottom line.

Long-Term Value Creation

RFID creates value beyond immediate operational improvements. The data collected enables predictive maintenance strategies, more informed purchasing decisions, and strategic asset planning based on actual usage patterns rather than guesswork.

Most organizations see return on investment within 12-18 months, with benefits continuing to accumulate as systems mature and users become more proficient.

Future Trends and Technology Evolution

RFID technology continues evolving rapidly, with new capabilities and applications emerging regularly. Staying informed helps you plan future enhancements and maintain competitive advantages.

Emerging Technologies and Integration Opportunities

Current developments include deeper integration with Internet of Things sensors, artificial intelligence for predictive analytics, and cloud-based platforms that simplify deployment and management.

Industry-Specific Innovations

Different industries are developing specialized applications that address unique operational requirements. Healthcare patient safety systems, manufacturing quality control, and retail loss prevention all represent RFID innovation areas worth watching.

The itemit platform stays current with these developments, continuously incorporating new capabilities whilst maintaining system stability and reliability.

Transform Your Asset Management with RFID

RFID asset tracking offers a practical solution to persistent asset management challenges. Rather than revolutionary change, it represents evolutionary improvement that builds on existing processes whilst eliminating common pain points.

The technology works because it addresses real problems: lost equipment, inaccurate inventory records, wasted time searching for assets, and missed maintenance schedules. By automating data capture and providing real-time visibility, RFID systems deliver measurable value whilst positioning businesses for future growth.

Success depends on realistic planning, appropriate technology selection, and thorough staff training. Done properly, RFID systems provide years of reliable service whilst continuously improving operational efficiency.

Ready to move beyond spreadsheets and manual processes? Discover how itemit’s RFID-enabled platform can provide the visibility and control your operation needs to thrive in today’s competitive environment.

Try itemit

Choose a better way to track your assets. Start your free 14-day trial now!

Frequently Asked Questions

What's the difference between RFID and barcode tracking?

RFID doesn’t require line-of-sight scanning and can read multiple tags simultaneously, whilst barcodes must be scanned individually with direct visibility.

How much does RFID implementation typically cost?

Costs vary significantly based on system scope, with passive tags costing 10p-£2 each and complete systems ranging from £5,000-£50,000 depending on requirements.

Yes, specialised tags are designed for extreme temperatures, moisture, chemicals, and other challenging conditions commonly found in industrial applications.

Passive tags typically work within 1-10 metres whilst active tags can be read from 100+ metres, depending on frequency and environmental conditions.

Is RFID technology secure for sensitive assets?

Modern RFID systems include encryption and authentication features, though security requirements should be evaluated based on specific asset sensitivity and risk levels.

Passive tags can function for decades without maintenance, whilst active tags typically require battery replacement every 3-5 years depending on usage patterns.

Can existing asset management systems integrate with RFID?

Most modern systems offer integration capabilities through APIs or direct database connections, though specific compatibility should be verified before implementation.