Have you ever walked through your warehouse feeling lost among countless items? Or faced an angry customer who couldn’t get their order because your system showed products that weren’t actually there? These everyday headaches point to a common solution: an effective inventory tracking process.

What Is Inventory Tracking and Why Is It Critical?

Inventory tracking is how businesses monitor and manage their stock throughout the supply chain. It’s not just counting what you have—it’s knowing exactly where each item is located, how it’s moving, and when it needs replenishing.

Real Business Impact of Effective Tracking

Companies often underestimate the importance of managing inventory until they calculate the numbers. Research shows businesses with solid inventory tracking systems typically cut carrying costs by 25% and reduce stockouts by nearly 40%. These figures translate directly to better profit margins and happier customers.

When you properly track inventory, you:

- Replace guesswork with concrete data

- Stop losing sales through stockouts

- Catch theft or shrinkage quickly

- Make your supply chain run smoothly

- Keep customers coming back because products are available

Every company handling physical products needs to understand why inventory is important. Without good tracking, you’re essentially working with yesterday’s information—or worse, just guessing.

The Inventory Tracking Process Explained

A well-designed inventory tracking process follows several key steps. Let’s examine each component:

Step 1: Receiving and Logging Inventory

Everything starts when goods arrive at your door. This initial phase of the inventory tracking process requires:

- Counting items against your purchase order

- Checking for damage or quality issues

- Creating or scanning unique identifiers

- Entering everything into your inventory management tracking system

Get this step wrong, and errors multiply throughout your entire operation. Accuracy here saves countless headaches later.

Step 2: Categorisation and Storage Mapping

Once items are received, they need homes. This inventory tracking process step involves:

- Grouping similar products together

- Assigning specific storage locations

- Documenting these locations digitally

- Creating an easily navigable system

Modern tracking systems for inventory include mapping features that slash the time spent searching for items. Asset tags play a crucial role here, allowing quick identification without opening boxes or digging through shelves.

Step 3: Tracking Movement and Usage

Inventory doesn’t sit still. As products move around, your inventory tracking process must capture:

- Transfers between departments

- Components used in manufacturing

- Items allocated to specific customers

- Returns requiring inspection

Many basic systems fail at this dynamic tracking. Solutions like the itemit asset tracking solution excel at maintaining visibility when inventory is constantly moving—whether across the room or across the country.

Step 4: Order Fulfilment Processes

When orders come in, your inventory tracking process should:

- Pinpoint exactly where needed items are stored

- Update inventory counts in real time

- Create efficient picking routes

- Monitor partial shipments

How quickly and accurately you fulfil orders directly reflects the strength of your inventory tracking process. Companies that master this stage gain a significant edge through better customer experiences and lower fulfilment costs.

Step 5: Regular Auditing and Reconciliation

No system is perfect without verification. Even excellent inventory tracking requires:

- Regular spot checks of specific sections

- Full physical counts at scheduled intervals

- Investigating any discrepancies

- Adjusting your inventory management tracking system accordingly

These audits keep your inventory tracking process honest, ensuring what your system shows matches what’s actually on your shelves.

Step 6: Reporting and Analytics

The final piece of a robust inventory tracking process is learning from your data. Good tracking systems for inventory provide:

- Stock turnover metrics

- Patterns in stockouts

- True cost of carrying inventory

- Projected demand curves

- Loss analysis

These insights transform raw numbers into strategic advantages, helping you continuously improve your inventory tracking process.

Modern Inventory Tracking Technology Solutions

The tools available for inventory tracking technology have come a long way from clipboards and paper counts.

Barcode vs RFID Systems: Choosing the Right Technology

When designing your inventory tracking process, technology choice matters:

- Barcode Systems: Budget-friendly but require direct scanning of each item individually. While inexpensive, these systems introduce more manual steps into your inventory tracking process.

- RFID Asset Tracking: These systems read multiple tags simultaneously without direct line-of-sight. RFID dramatically speeds up your inventory tracking process while reducing human error. The itemit asset tracking solution uses RFID technology to deliver enterprise-level capabilities without the enterprise-level price tag.

Cloud-Based Inventory Management Systems

Cloud-powered inventory tracking process solutions provide instant updates across locations, preventing duplicate orders and stockouts. Items scanned in one facility are immediately updated system-wide, creating a single source of inventory truth.

Cloud-based inventory management tracking systems synchronise product data automatically with e-commerce, accounting, and shipping platforms. Staff can access inventory information from any device, eliminating dependence on fixed workstations.

Robust data protection, redundant backups, and superior security are standard features of cloud solutions. These systems scale with simple configuration changes instead of major investments, allowing businesses to adapt without the expenses of traditional systems.

Mobile Inventory Tracking Applications

Mobile devices bring the inventory tracking process directly to your products. Staff scan items on-site without manual recording, reducing errors while capturing accurate data faster with less effort.

Smartphones become powerful inventory tools without specialised hardware costs. Photo documentation attaches to records for visual verification, aiding dispute resolution and training while increasing system adoption.

Voice commands enable hands-free inventory tracking process operations when handling items or wearing gloves. Real-time alerts notify staff of stock issues before they become problems, maintaining inventory vigilance without administrative burden.

The Business Impact of Effective Inventory Tracking

Understanding the importance of managing inventory goes well beyond just keeping track of stuff. Let’s look at the real business benefits.

Financial Benefits: Cost Reduction and Improved Cash Flow

A streamlined inventory tracking process delivers measurable financial results:

- Lower carrying costs (which typically eat up 20-30% of inventory value each year)

- Fewer write-offs for expired or damaged goods

- Reduced rush shipping expenses

- Better cash flow through appropriate stocking levels

- More accurate tax reporting through precise valuation

These financial advantages demonstrate why inventory is important to your bottom line.

Operational Benefits: Efficiency and Productivity

Beyond money saved, good inventory tracking makes operations smoother:

- Faster picking and packing

- Less time hunting for missing items

- Better use of warehouse space

- More productive employees

- Smoother workflows between departments

These operational improvements create competitive advantages that make the inventory tracking process excellence a strategic asset.

Customer Satisfaction Through Product Availability

Perhaps the most compelling reason why inventory is important connects to your customers:

- Fewer disappointed shoppers due to out-of-stock items

- More accurate delivery promises

- Ability to show real-time availability online

- Quicker order processing

- Stronger customer loyalty and trust

In the market of nowadays when consumers need instant satisfaction, your inventory tracking process directly impacts customer retention and growth.

Implementing an Effective Inventory Tracking System with itemit

Moving to a better inventory tracking process requires thoughtful planning and execution. Most successful implementations follow a structured approach that balances immediate needs with long-term goals.

Assessment of Current Inventory Processes

Before introducing new inventory tracking technology, thoroughly evaluate your current operations. Start by examining your biggest pain points—perhaps excessive stockouts, inaccurate counts, or inefficient picking routes. Document your existing workflows, noting where delays or errors typically occur. Measure your current accuracy rates and quantify how often inventory discrepancies happen. This data provides crucial benchmarks.

Next, calculate the actual costs of your inventory problems. Include obvious expenses like emergency shipping and lost sales, as well as hidden costs such as extra labour hours spent searching for misplaced items or reconciling inaccurate records. Finally, define concrete success metrics so you’ll know when your improved inventory tracking process is delivering results. This comprehensive assessment creates a solid foundation for justifying and guiding your inventory system improvements.

Setting Clear Objectives for Your Inventory System

Successful inventory tracking process improvements require specific, measurable goals. Begin by determining exactly how much you want to reduce carrying costs—perhaps targeting a 15% reduction in the first year. Establish clear fulfilment rate targets, such as moving from 92% to 98% complete orders on time. Set specific accuracy benchmarks that reflect your business needs; medical suppliers might aim for 99.9% accuracy, while retail operations might find 98% sufficient.

Consider efficiency gains in concrete terms: reducing picking time by 30% or cutting cycle count hours by half. Develop a realistic timeline with clear implementation phases that account for your business cycles and busy periods. These well-defined objectives give your team clear direction and provide measurable waypoints to evaluate progress as your inventory tracking process evolves.

Selecting the Right Tools and Technologies

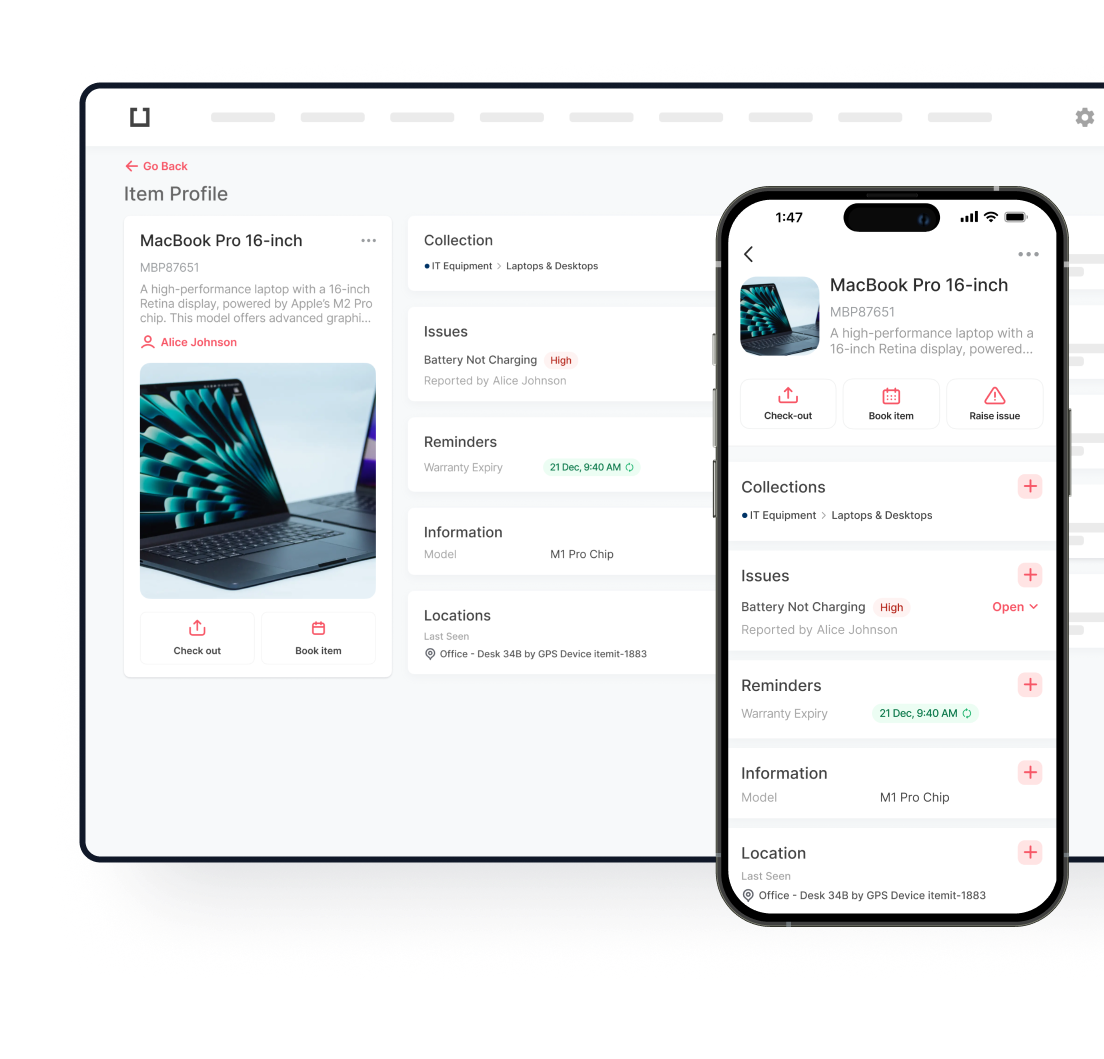

The itemit asset tracking solution stands out for its comprehensive approach to inventory tracking process improvement. Unlike single-purpose systems, itemit offers flexibility through multiple tagging options—allowing you to use barcodes for bulk items, QR codes for location tracking, and RFID for high-value or frequently moved inventory. This versatility means you can implement the most appropriate tracking method for each inventory category.

The cloud-based management portal eliminates the need for expensive servers while providing real-time visibility from anywhere. Mobile applications for both iOS and Android put inventory management in your team’s pockets, enabling updates and checks on the warehouse floor. Custom reporting tools transform raw data into actionable insights tailored to your specific business needs. Perhaps most importantly, itemit’s open architecture integrates smoothly with existing business systems, from accounting software to e-commerce platforms, creating a unified inventory tracking process without requiring a complete system overhaul.

Implementation Strategies and Best Practices

Successfully rolling out your new inventory tracking process requires careful change management. Rather than attempting a complete system changeover, identify a single department or inventory category for your initial implementation. This pilot program allows you to refine procedures while demonstrating value in a controlled environment. Comprehensive training proves essential—focus not just on system mechanics but on how the inventory tracking process improves each person’s daily work.

Develop clear, documented procedures for every aspect of system use, from receiving new inventory to handling exceptions. Assign specific responsibilities to team members, creating accountability and ownership of the new processes. Implement your system in manageable phases, addressing core functions first before adding more sophisticated capabilities. This measured approach builds momentum through early wins while preventing the disruption that often accompanies large-scale changes. By following these implementation best practices, your new inventory tracking process will gain broad acceptance and deliver maximum value.

Advanced Inventory Traceability for Modern Businesses

As businesses grow more complex, inventory tracking process requirements evolve. Advanced inventory traceability represents the next level of sophistication.

Lot Tracking and Serial Number Importance

Enhanced inventory traceability includes:

- Tracking individual items with unique serial numbers

- Managing products by production batches

- Recording manufacturing dates

- Monitoring expiration timeframes

- Documenting the chain of custody

These capabilities prove especially important in regulated industries where inventory traceability directly connects to compliance requirements.

Supply Chain Transparency and Accountability

Modern inventory tracking process extends beyond your walls:

- Seeing supplier inventory levels

- The following items are in transit

- Working closely with distribution partners

- Viewing your entire supply chain

- Sharing inventory data strategically

This expanded perspective transforms your inventory tracking process into a competitive edge through better partnerships and planning.

Quality Control Through Comprehensive Tracking

Advanced inventory tracking supports quality programs by:

- Enabling precise recalls when needed

- Spotting patterns in defects

- Setting up automatic quality checkpoints

- Recording inspection results

- Managing quarantined items effectively

When quality issues arise, good inventory traceability allows for surgical precision in your response.

From Tracking to Thriving

The inventory tracking process forms a cornerstone of operational success. By implementing thoughtful approaches to tracking inventory, businesses reduce expenses, delight customers, and gain market advantages.

Inventory tracking technology continues advancing with AI, machine learning, and IoT, bringing new capabilities every year. Staying current with these tools ensures your inventory tracking process becomes a strength rather than a weakness.

Want to transform your inventory tracking process? The itemit asset tracking solution offers a flexible, user-friendly platform designed for businesses of all sizes. Our approach combines powerful technology with practical implementation to deliver quick wins and long-term success.

Learn more about how to Improve Order and Inventory Management, or contact us today to see how the itemit asset tracking solution can revolutionise your inventory tracking process.

Beyond money saved, good inventory tracking makes operations smoother:

- Faster picking and packing

- Less time hunting for missing items

- Better use of warehouse space

- More productive employees

- Smoother workflows between departments

These operational improvements create competitive advantages that make the inventory tracking process excellence a strategic asset.

Try itemit

Choose a better way to track

your assets.

Start your free 14-day trial now!

Keep Learning

itemit Blog

Tips, guides, industry best practices, and news.

The Ultimate Guide to RFID Inventory Management

Discover the beginner’s guide to RFID inventory management technology. Learn how to improve accuracy, streamline stock tracking, and boost efficiency today!

A Guide to the Different Types of Inventory Management

Discover the different types of inventory management systems and how each can improve efficiency and accuracy in managing your business inventory.

How to Choose the Right Inventory Scanner for Your Business

Use our guide to choose the right inventory scanner for your business. Learn which features matter, compare types, and get tips for selecting the best fit.