Success or failure in today’s competitive business landscape often hinges on how effectively a company monitors and controls its assets and stock. Quietly powering many of the most effective tracking operations is the unassuming 2D barcode – a technology that seldom receives the recognition it deserves. These square-patterned data carriers represent a quantum leap beyond conventional linear barcodes. With their ability to pack extensive information into remarkably compact spaces, these versatile two-dimensional barcodes have fundamentally transformed operational processes across industries – from warehouse management to point-of-sale interactions and from field service tracking to customer engagement.

What Are 2D Barcodes?

A 2D barcode stores information in both horizontal and vertical patterns—that’s where the term 2 dimensional barcode comes from. Traditional linear barcodes (the familiar zebra-striped pattern) only hold about 20-25 characters, but their more advanced 2D cousins pack hundreds or thousands of characters into a similarly sized space.

What are 2D barcodes capable of storing? These compact data powerhouses can contain:

- Plain text information

- Web addresses and URLs

- Complete contact details

- Serial and tracking numbers

- Detailed product specifications

- Equipment maintenance histories

- Precise location coordinates

This extensive data capacity makes 2D barcodes particularly valuable for businesses managing assets and inventory at scale.

Barcode Origins and Evolution

Barcodes have a longer history than many realize. Norman Joseph Woodland and Bernard Silver filed the first patent for a barcode-type system back in 1949, though it looked quite different from today’s versions. The familiar UPC (Universal Product Code) that transformed retail was invented in the early 1970s, with its first commercial use scanning a pack of Wrigley’s gum in 1974.

The jump to 2D barcodes happened later. Symbol Technologies developed the first true 2D barcode—PDF417—in 1991. Then, in 1994, Denso Wave created QR codes in Japan to track automotive parts during manufacturing.

When was barcode technology widely adopted beyond retail scanning? The smartphone boom of the late 2000s changed everything, essentially putting a barcode scanner in millions of pockets worldwide.

Types of 2D Barcodes

While QR codes dominate public awareness, the 2D barcode family includes several distinct formats with unique strengths:

1. QR (Quick Response) Codes:

- Capacity: Up to 7,089 numeric or 4,296 alphanumeric characters

- Distinctive Feature: Three-position detection patterns in corners

- Best For: Consumer-facing applications, marketing, payments

- Error Correction: Can restore up to 30% of damaged data

- Scanning Speed: Extremely fast (hence “Quick Response”)

- Mobile Compatibility: Excellent native support on most smartphones

2. Data Matrix:

- Capacity: Up to 2,335 alphanumeric characters

- Distinctive Feature: Square or rectangular grid with finder pattern

- Best For: Marking small components, medical devices, electronic components

- Error Correction: Reed-Solomon algorithm allows reading even when 20-30% damaged

- Size Advantage: Can be printed extremely small (as tiny as 2×2 mm)

- Industry Adoption: Aerospace, defense, electronics manufacturing

3. Aztec Code:

- Capacity: Up to 3,832 numeric or 3,067 alphanumeric characters

- Distinctive Feature: Square bullseye pattern at center

- Best For: Transportation tickets, boarding passes, ID verification

- Error Correction: Adjustable levels from 5% to 95%

- Scanning Benefit: No quiet zone required around the symbol

- Standards: ISO/IEC 24778 compliant for global use

4. PDF417:

- Capacity: Up to 1,800 characters

- Distinctive Feature: Stacked linear barcode resembling a pile of 1D codes

- Best For: ID cards, driver’s licenses, inventory management

- Error Correction: Nine levels available depending on security needs

- Format Type: Technically a “stacked linear” rather than matrix code

- Government Use: Common on government-issued identification documents

5. MaxiCode:

- Capacity: Up to 93 characters, optimized for shipping information

- Distinctive Feature: Hexagonal grid with bullseye center

- Best For: High-speed sorting and tracking of packages

- Creator: Developed by UPS for their shipping operations

- Scanning Benefit: Designed for ultra-high-speed conveyor scanning

- Industry Standard: Used globally in logistics and shipping

Understanding these distinct formats helps businesses select the optimal 2D barcode type for specific operational needs rather than defaulting to the most familiar option. The right selection can dramatically improve scanning reliability, data security, and overall system efficiency.

2D Barcode vs QR Code: Important Distinctions

Understanding these distinct formats helps businesses select the optimal 2D barcode type for specific operational needs rather than defaulting to the most familiar option. The right selection can dramatically improve scanning reliability, data security, and overall system efficiency.

People often use “QR code” and “2D barcode” as synonyms, but that’s not technically correct. The relationship in the 2D barcode vs. QR code comparison is category versus specific type—QR codes are just one format within the broader 2D barcode family.

Key differences to understand about 2D barcode vs QR code:

- Classification: The term “2D barcode” covers many formats (QR, Data Matrix, Aztec, etc.), while “QR code” means one format.

- Visual Design: QR codes feature distinctive square finder patterns in three corners; other 2D barcodes use different identifying markers.

- Data Storage: Some 2D barcode types exceed QR codes in storage capacity, while others optimize for specific data types.

- Best Uses: QR codes typically work better for consumer-facing applications, but other 2D barcode formats often prove superior for industrial or specialized tasks.

This distinction matters because defaulting to QR codes without considering alternatives might mean missing out on a format better suited to your specific requirements.

How 2D Barcodes Improve Business Operations

Implementing 2D barcodes as part of your asset-tracking solution delivers measurable improvements across multiple operational areas:

Enhanced Data Management

Rich Data Encoding

- Store complete asset profiles (150+ characters) directly in a single code

- Include maintenance histories, ownership records, and technical specifications

- Encode URLs that link to cloud-based asset records for unlimited information

- Embed serialization data that uniquely identifies each item

Damage-Tolerant Information

- Maintain readability even when 30% of the code is damaged or obscured

- Continue functioning in harsh environments with dirt, scratches, or partial damage

- Reduce replacement costs for labels in high-wear locations

- Ensure critical data remains accessible during emergency situations

Operational Efficiency Gains

Space Optimization

- Fit complete data into 1/10th the space of traditional barcodes

- Apply functional codes to small components previously too tiny to tag

- Reduce label size by up to 80% while increasing data capacity

- Maintain brand aesthetics with smaller, less obtrusive tracking codes

Scanning Improvements

- Reduce scanning time by 60-70% with omnidirectional reading capability

- Eliminate alignment issues that plague traditional barcode systems

- Enable scanning from distances up to 3x greater than 1D codes

- Function effectively in low-light environments where 1D codes fail

Cost-Effective Implementation

Technology Investment Comparison

- Implement at 15-25% the cost of comparable RFID systems

- Create new codes with standard printers rather than specialized equipment

- Eliminate ongoing tag costs through digital distribution of codes

- Leverage existing smartphones instead of purchasing dedicated scanners

Maintenance Economies

- Reduce label replacement frequency by up to 60% through better durability

- Decrease scanning errors by 70-80%, cutting exception-handling labor costs

- Lower training requirements through intuitive scanning processes

- Minimize database storage requirements through compressed data formats

Security Enhancements

Authentication Features

- Incorporate encrypted authentication data that prevents unauthorized duplication

- Add digital signatures to verify code authenticity

- Implement version control to identify outdated or recalled items

- Create visual security elements that help identify tampering attempts

Access Control Integration

- Link scanning to user authorization levels for sensitive assets

- Create audit trails that record every scan with user identification

- Restrict certain data elements to users with appropriate clearance

- Enable temporary access grants for contractors or visitors

Compatibility Advantages

Universal Data Support

- Encode non-Latin alphabets for global operations without translation issues

- Store binary data for direct machine-to-machine communication

- Include images such as component diagrams or safety symbols

- Support multiple languages within a single code

Device Flexibility

- Scan using any smartphone camera without specialized equipment

- Works across Android, iOS, and Windows mobile platforms

- Function with existing enterprise scanners through firmware updates

- Integrate with wearable technology for hands-free operations

The cumulative effect of these advantages makes 2D barcodes the optimal choice for businesses implementing an asset-tracking solution that requires maximum functionality with minimal implementation complexity. Companies typically report 30-40% overall efficiency improvements after transitioning from traditional barcodes to a comprehensive 2D barcode system.

2D Barcodes in Action: Practical Applications

2D barcodes and 2D labels have practical applications across numerous industries:

Manufacturing:

- Tracking components through complex production processes

- Documenting quality control checks and results

- Storing machine maintenance logs directly on equipment

Healthcare:

- Patient identification systems that reduce medical errors

- Medication verification protocols at administration

- Medical equipment tracking with durable 2D labels

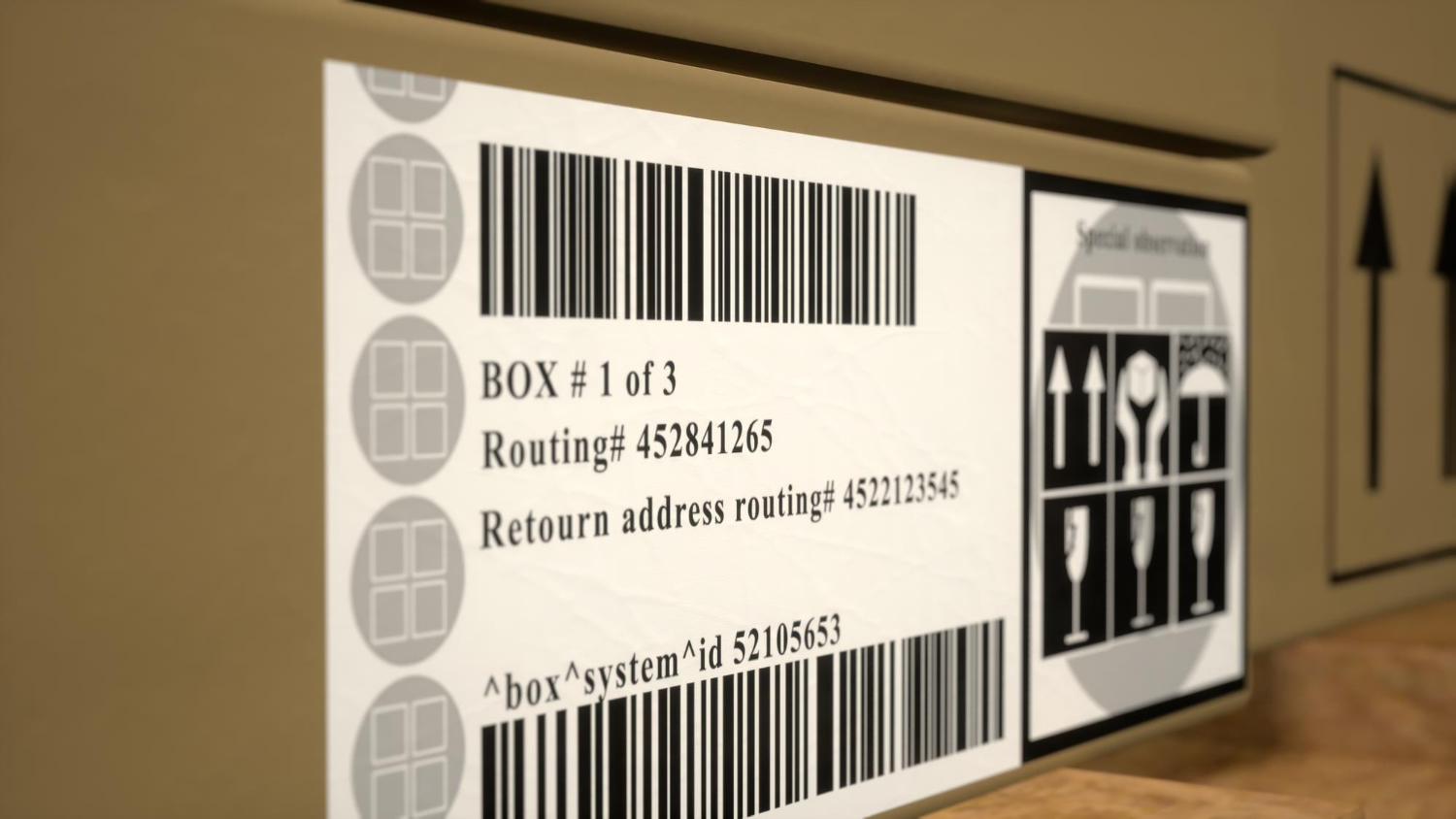

Retail and Logistics:

- Detailed inventory control systems

- Package routing and tracking throughout distribution

- Product authentication systems that fight counterfeiting

Field Services:

- Equipment identification using weather-resistant 2D labels

- Instant access to maintenance records via asset tags

- Component compatibility verification before installation

Construction:

- Tool and heavy equipment monitoring

- Material validation and tracking

- Safety inspection documentation through 2D barcode scanning

The flexibility of 2D barcode technology means virtually any industry can boost efficiency by implementing these information-rich codes alongside physical asset tags.

Setting Up 2D Barcodes with Your Asset System

Implementing 2D barcodes requires thoughtful planning and execution. Here’s a comprehensive approach to maximizing your return on investment:

1. Strategic Format Selection

Different 2D barcode formats serve different purposes:

- QR Codes: Choose for consumer-facing applications or when smartphone scanning is primary

- Data Matrix: Ideal for small components or items with limited space

- Aztec Code: Best for applications requiring high data density or where damaged code reading is common

- PDF417: Select when compatibility with existing ID systems is needed

- MaxiCode: Optimal for high-speed logistics operations

Consider scanning environment, data volume, and reader technology when making your selection.

2. Material and Durability Considerations

Match your asset tags to their operating environment:

- Indoor Office Use: Standard paper or vinyl labels work well

- Warehouse Settings: Polyester labels with protective coatings resist scuffing

- Outdoor Exposure: UV-resistant polyester or metal asset tags prevent fading

- Chemical Exposure: Chemical-resistant labels with additional lamination

- Extreme Temperatures: Specialized high/low temperature materials (-80°C to +180°C)

- Tamper Evidence: Security materials that show evidence of removal attempts

The durability of your 2D labels directly impacts scanning reliability and maintenance costs.

3. Integration with Existing Systems

Effective implementation requires seamless connection with your asset-tracking solution:

- Database Structure: Define how barcode data maps to your asset database fields

- API Connections: Ensure your scanning devices communicate properly with backend systems

- Mobile App Compatibility: Test scanning with all devices your team uses

- Data Synchronization: Plan for offline scanning with later database updates

- Legacy System Bridging: Create middleware if needed to connect with older systems

- Security Protocols: Implement proper authentication for barcode-triggered data access

Proper integration prevents data silos and ensures information flows where needed.

4. Staff Training and Adoption

Even perfect technology fails without proper use:

- Scanning Technique Training: Ensure staff knows proper distances and angles for reliable reads

- Troubleshooting Skills: Teach basic problem-solving for common scanning issues

- Process Workflow Integration: Document exactly when and how scanning should occur

- Benefits Communication: Help staff understand how the system improves their work

- Champions Program: Designate and train power users who can help others

- Feedback Mechanism: Create a system for reporting issues and suggesting improvements

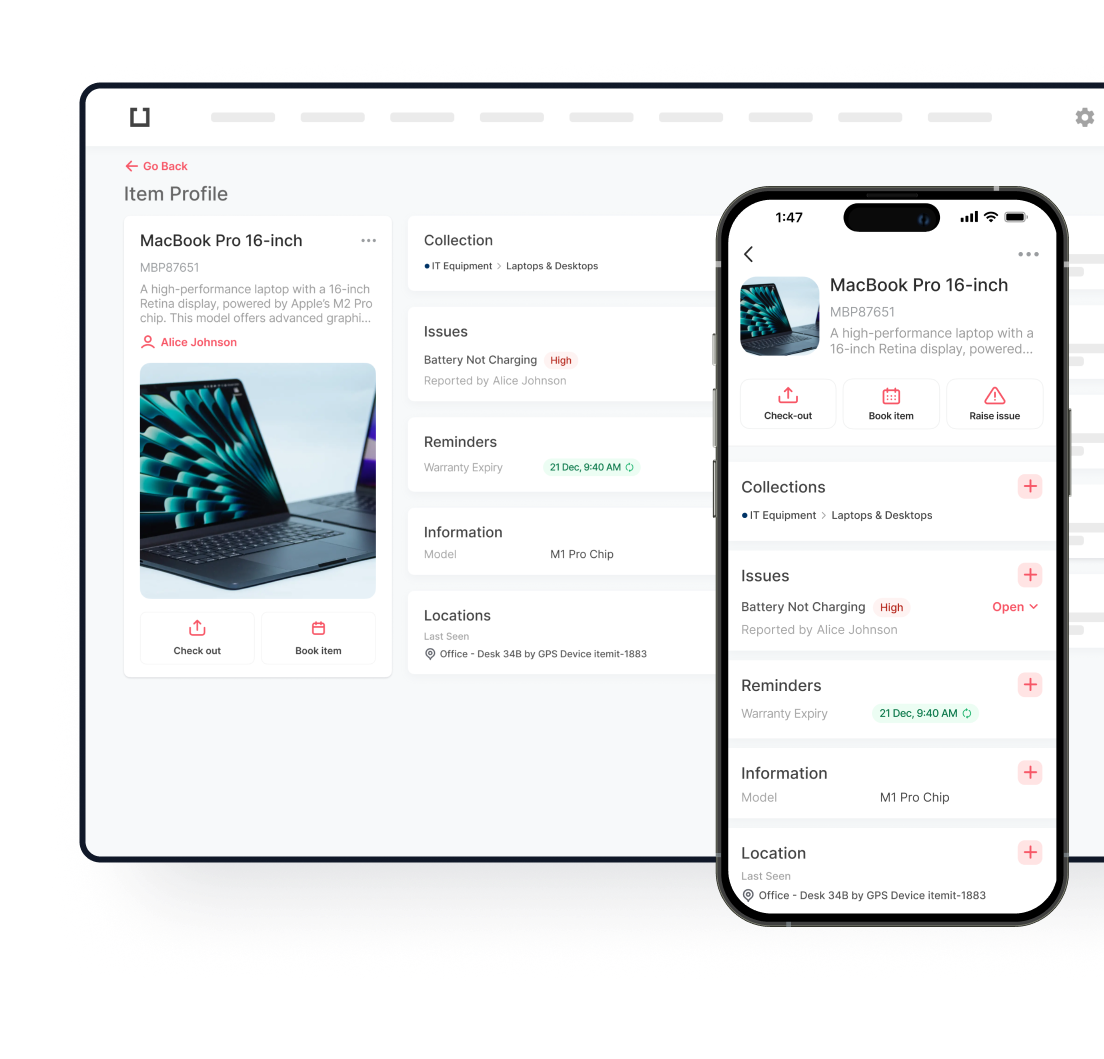

The itemit asset tracking solution removes much of this complexity with a platform specifically designed for 2D barcode deployment. With itemit, you can rapidly implement custom asset tags featuring 2D barcodes tailored to your specific requirements, all supported by powerful software that makes asset data instantly accessible.

Where 2D Barcodes Are Heading Next

2D barcode technology continues to evolve. Key developments to watch:

- Advanced Security Features: Newer 2D barcode generations incorporate sophisticated anti-tampering elements.

- Visual Customization: Emerging formats allow brand colors and logo integration without compromising functionality.

- AR Capabilities: 2D barcodes increasingly serve as triggers for augmented reality experiences.

- Green Materials: Development of environmentally sustainable materials for 2D barcode printing.

- Higher Capacity Formats: New designs push boundaries on information density.

- Blockchain Connection: Linking 2D barcodes with blockchain for tamper-proof verification chains.

These innovations will further strengthen the role of 2D barcodes in business infrastructure.

The Power of Small Squares: What's Next for Your Business

Interesting Barcode Facts and Moving Forward

Barcode facts often surprise even technology professionals. Did you know the first scanned commercial barcode was on Wrigley’s chewing gum? Or can modern 2D barcodes hold enough text for an entire technical manual?

2D barcode technology offers one of the most accessible yet powerful tools for operational improvement. From streamlined inventory management to comprehensive asset tracking, these compact data carriers deliver significant value without requiring complex implementation.

Ready to upgrade your operations with 2D barcode technology? The itemit asset tracking solution provides a complete system for 2D barcode implementation, with customized asset tags, powerful tracking software, and expert support.

Take your next step toward operational excellence by discovering how the itemit asset tracking solution can help your organization effectively harness 2D barcodes. Contact us today for a personalized demonstration.

Try itemit

Choose a better way to track your assets. Start your free 14-day trial now!

Keep Learning

itemit Blog

Tips, guides, industry best practices, and news.

Benefits of Vendor Managed Inventory for Your Business

Learn how Vendor Managed Inventory (VMI) can streamline your supply chain. Explore the key benefits and how it helps optimize inventory management.

The Key to Asset Reliability: Preventive Maintenance and Real-Time Tracking

Enhance asset reliability with preventive maintenance and real-time tracking. Reduce downtime, improve efficiency, and extend asset lifespan with smart strategies.

Optimising Asset Performance Management: Strategies for Maximum Efficiency

Explore practical strategies to optimise asset performance management, maximise efficiency, and enhance productivity with predictive and real-time monitoring tools.