Running a business comes with countless challenges, but few are as persistent as inventory management. Too much inventory ties up capital and warehouse space. Too little leads to stockouts and unhappy customers. This balancing act consumes time, resources, and energy that could be directed elsewhere.

Vendor-managed inventory offers a solution to this persistent headache. By shifting inventory management responsibility to suppliers who understand their products best, businesses can focus on their core competencies while maintaining optimal stock levels.

What Is Vendor Managed Inventory?

VMI stands for Vendor–Managed Inventory, a collaborative inventory management practice in which your supplier takes responsibility for maintaining your inventory levels. Unlike traditional ordering systems, where you monitor stock and place orders, with VMI, your supplier tracks your inventory levels and makes replenishment decisions.

The vendor-managed inventory model works by establishing minimum and maximum inventory thresholds based on your consumption patterns. Your supplier then monitors these levels (often through technology integration) and replenishes stock automatically when needed – without requiring purchase orders for each shipment.

Under this arrangement, your supplier accesses your inventory data, stock is replenished based on actual consumption, and ownership of goods typically transfers upon delivery. Billing occurs after delivery rather than upon order placement, creating a more streamlined financial flow.

The VMI supply chain represents a significant shift from traditional models. Instead of operating in silos where information flows one way, VMI creates an integrated supply network with continuous information sharing between you and your suppliers, resulting in greater efficiency and responsiveness.

Core Benefits of Vendor Managed Inventory

Lower Operating Costs

Vendor-managed inventory directly reduces costs through multiple mechanisms. Most businesses report administrative cost savings of 55-75% when they eliminate the purchase order cycle. Precise inventory management also means less capital tied up in stock, with many companies seeing a 20-30% reduction in carrying costs, according to a 2023 supply chain study.

Better space utilisation through vendor-managed inventory translates to decreased warehouse expenses. A mid-sized manufacturing company implementing VMI reported a 73% decrease in emergency shipments within six months, saving over $45,000 annually on premium freight alone.

The cost benefits of VMI include:

- Reduced procurement administrative overhead

- Lower inventory carrying costs

- Decreased emergency shipping expenses

- Minimised obsolescence write-offs

- Improved cash flow through optimised inventory levels

For many businesses, these combined savings amount to 10-15% of total inventory management costs – a significant boost to your bottom line.

Minimised Stock Issues

When your inventory vendor manages replenishment, stock problems diminish dramatically. Companies implementing VMI typically see stockouts decrease by up to 80% while simultaneously reducing excess inventory. This reliability translates directly to customer satisfaction and operational stability.

Take the case of a regional healthcare provider that struggled with supply shortages before implementing vendor-managed inventory. After six months with their key suppliers managing replenishment, stock availability increased from 92% to 99.6%, virtually eliminating the clinical workarounds previously required.

The consistent availability created by VMI proves particularly valuable for manufacturing operations, where even small component shortages can halt production lines, costing thousands per hour. Similarly, companies in the construction sector use VMI alongside construction equipment tracking to ensure both materials and equipment are available when needed at job sites. By transferring inventory responsibility to suppliers with better visibility into their supply chains, businesses gain reliability that directly impacts customer satisfaction and revenue protection.

Streamlined Processes

With vendor-managed inventory, your procurement process transforms from a complex, multi-step operation to a streamlined oversight function. Rather than constant monitoring, ordering, approving, tracking, and processing, your team sets performance parameters, receives automated replenishments, and validates consolidated invoices.

The traditional procurement cycle typically involves:

- Monitoring inventory levels

- Creating purchase requisitions

- Obtaining approvals

- Issuing purchase orders

- Tracking deliveries

- Processing receipts

- Managing invoices

VMI eliminates most of these steps, freeing staff for value-adding activities while reducing errors and oversight requirements. Many businesses discover they can reallocate 15-20 hours per week of procurement staff time to strategic sourcing and supplier relationship management after implementing VMI.

Enhanced Cash Flow

Cash flow benefits of vendor-managed inventory extend beyond the obvious inventory reduction. Because bills arrive after goods are received rather than when ordered, your payment timing aligns better with your actual usage. This timing difference, combined with the reduced capital requirements of lower inventory levels, creates significant financial flexibility.

VMI relationships typically result in more favourable payment terms since suppliers value the arrangement’s predictability. Eliminating rush shipping and production disruptions also stabilises your cash flow by removing unexpected emergency costs that would otherwise disrupt financial planning.

Strategic Advantages for Your Business

Beyond operational benefits, vendor-managed inventory delivers strategic value that can transform your competitive position.

Strengthened Supplier Partnerships

When your inventory vendor manages your stock, your relationship evolves from transactional to strategic. Suppliers become invested in your success, creating benefits that extend far beyond inventory management.

This partnership transformation often results in preferred customer status during shortages – a critical advantage when supply chains tighten. One electronics manufacturer credited their VMI relationship with maintaining 100% production during the chip shortage while competitors faced weeks of downtime.

Vendor-managed inventory creates collaborative relationships where suppliers gain firsthand knowledge of your operations. This insider perspective allows them to spot improvement opportunities invisible to outsiders and grants you early access to product innovations before your competitors.

Partnership advantages of VMI include:

- Priority allocation during supply constraints

- Custom packaging or product configurations

- Advanced notice of product changes

- More favourable pricing structures

- Joint problem-solving capabilities

Access to Specialised Expertise

Your suppliers know their products better than anyone. Through vendor-managed inventory, you gain market intelligence on product trends and availability that would be difficult to access otherwise. Suppliers managing your inventory develop insights on your usage patterns and can recommend optimisation strategies based on what they’ve learned from their entire customer base.

This knowledge transfer often proves as valuable as the operational benefits of VMI. A food processing company implementing vendor-managed inventory for packaging materials received supplier recommendations that reduced material usage by 14% without compromising product protection – an improvement they hadn’t even been seeking when starting the program.

The supplier expertise gained through VMI relationships frequently leads to process improvements, product standardisation opportunities, and application optimisations that create cascading benefits throughout your operation.

Competitive Differentiation

While competitors struggle with inventory challenges, your VMI supply chain advantages let you react faster to market changes and maintain higher service levels. This responsiveness creates a significant competitive advantage, particularly in industries where availability drives customer decisions.

By freeing resources from routine inventory management, you can focus on core competencies and strategic initiatives while scaling operations without proportional inventory growth. This focus on differentiation rather than commodity functions often separates market leaders from followers.

Risk Mitigation

Vendor-managed inventory reduces business risk through decreased obsolescence and lower liability exposure. Suppliers managing your inventory typically take greater responsibility for product lifecycles, reducing the chance you’ll be left with outdated stock. Reduced inventory levels also mean reduced insurance requirements and less capital at risk.

VMI partnerships unlock preferential treatment during supply constraints. Suppliers consistently place their VMI customers at the front of the line when materials grow scarce, protecting your operations while competitors face disruptions.

Key risk reduction factors include:

- Decreased obsolescence through better lifecycle management

- Lower insurance and carrying costs from reduced inventory

- Priority allocation during supply constraints

- Greater supply chain visibility and early warning of disruptions

- Flexibility to adjust quickly to changing market conditions

VMI Implementation Considerations

Successful vendor-managed inventory requires careful planning and clear expectations. The foundation of an effective program includes several key elements that must be addressed before launch.

Technology Foundation

Effective VMI depends on technology integration that provides inventory visibility systems, giving your supplier real-time or near-real-time access to stock levels. This visibility requires established data exchange protocols for sharing consumption information and forecasts.

Most successful implementations include automation capabilities with systems that can generate alerts and replenishment signals without human intervention. Performance tracking tools complete the technology picture, providing dashboards to monitor KPIs and program success.

The technology requirements include four essential components:

- Inventory visibility tools – Systems tracking stock levels and consumption

- Data exchange platforms – Methods for securely sharing information with suppliers

- Automation systems – Technologies triggering replenishment without manual intervention

Analytics capabilities – Tools measuring performance and identifying improvement opportunities

Communication Framework

Clear communication prevents misunderstandings in any vendor-managed inventory program. Start by developing service level agreements that document expectations for fill rates, delivery times, and inventory turns. Establish a regular review cadence with scheduled assessments of performance metrics.

Exception handling protocols define processes for addressing unusual situations like demand spikes or supply disruptions. Clear escalation paths ensure everyone knows who to contact for resolving issues quickly when problems arise.

The most successful VMI programs include regular performance reviews that examine trends rather than individual incidents. These reviews create opportunities for continuous improvement while maintaining focus on the strategic partnership rather than transaction-level details.

Performance Metrics and Responsibilities

You can’t improve what you don’t measure. Critical VMI metrics include inventory turns, fill rates, stock availability percentage, and emergency order frequency. Tracking these metrics, along with carrying costs and order processing costs, provides visibility into program performance and improvement opportunities.

Under VMI, the vendor is responsible for monitoring inventory levels, determining replenishment timing and quantities, maintaining agreed service levels, and providing performance reports. You remain responsible for setting overall inventory parameters, providing accurate consumption data, communicating forecast changes, and evaluating program performance.

This clear delineation of responsibilities creates accountability while allowing each party to focus on what they do best. The supplier manages the details of inventory replenishment, while you maintain strategic control of the program parameters and direction.

How To Choose The Right Inventory Vendor

Not all suppliers make good VMI partners. Look for partners with supply chain maturity demonstrated through forecasting capabilities, strong logistics performance, and technology infrastructure for inventory management. Experience with VMI programs is particularly valuable, as it indicates familiarity with the unique challenges of managing someone else’s inventory.

When selecting VMI partners, evaluate them based on:

Supply Chain Capabilities

- Proven forecasting accuracy

- Effective inventory management systems

- Reliable logistics performance

- Previous VMI program experience

Relationship Qualities

- Open communication practices

- Business culture compatibility

- Long-term partnership focus

- Financial health and stability

Relationship factors matter tremendously in successful vendor-managed inventory. Trust and transparency form the foundation, while compatible business cultures ensure smooth collaboration. Long-term relationship orientation indicates commitment to mutual success, and financial stability prevents disruptions due to supplier difficulties.

Technical capabilities determine how smoothly the implementation will proceed. Systems compatibility with your platforms, robust data security protocols, and reporting flexibility facilitate effective information sharing. A commitment to continuous improvement processes ensures the relationship evolves as your needs change.

The right inventory vendor demonstrates service orientation through responsive problem resolution and proactive communication. Adaptability to changing requirements prevents rigidity that could undermine program benefits, while investment in relationship management indicates a long-term partnership commitment.

Getting Started With VMI

Program Design

Many businesses ask how to optimise product inventory management when beginning their VMI journey. The answer lies in a strategic approach: start with accurate baseline inventory data, establish clear performance metrics that align with business goals, focus initially on high-value stable-demand items, conduct regular program reviews with suppliers, and leverage technology for real-time visibility.

Begin by identifying appropriate product categories for VMI. The best candidates typically include:

- Items with relatively stable demand patterns

- Products from suppliers with whom you have strong relationships

- Categories where availability is critical to your operation

- Items with significant storage requirements or carrying costs

Establish clear inventory targets and service levels that balance your operational needs with reasonable supplier expectations. Design communication protocols that specify frequency, format, and content of information exchanges. Finally, develop performance metrics that measure both process execution and business outcomes.

Partner Selection and Pilot Implementation

Select partners based on product importance to your operations, supplier capability assessment, relationship history, and technology compatibility. Start with a pilot implementation covering a limited product range in a single location if possible. Define clear success metrics and an evaluation period so everyone understands what constitutes success.

The pilot phase provides valuable learning opportunities while limiting risk. Many companies discover unforeseen challenges during pilots that can be addressed before broader rollout. These might include data accuracy issues, internal resistance, forecast variability challenges, or trust barriers that must be overcome.

Technology Integration and Full Deployment

Focus on technology integration by establishing data sharing protocols, implementing inventory visibility tools, and creating performance dashboards. These technical foundations support the information flow critical to VMI success.

Once your pilot succeeds, scale through full deployment by adding products incrementally, expanding to additional locations, refining processes based on learnings, and building on successful relationships. This measured expansion allows you to maintain control while steadily increasing benefits.

Throughout implementation, anticipate common challenges. Data accuracy issues can undermine VMI effectiveness, so invest in inventory counting accuracy and system integration before launching. Internal resistance often surfaces during implementation; address it by educating staff on benefits and involving them in program design.

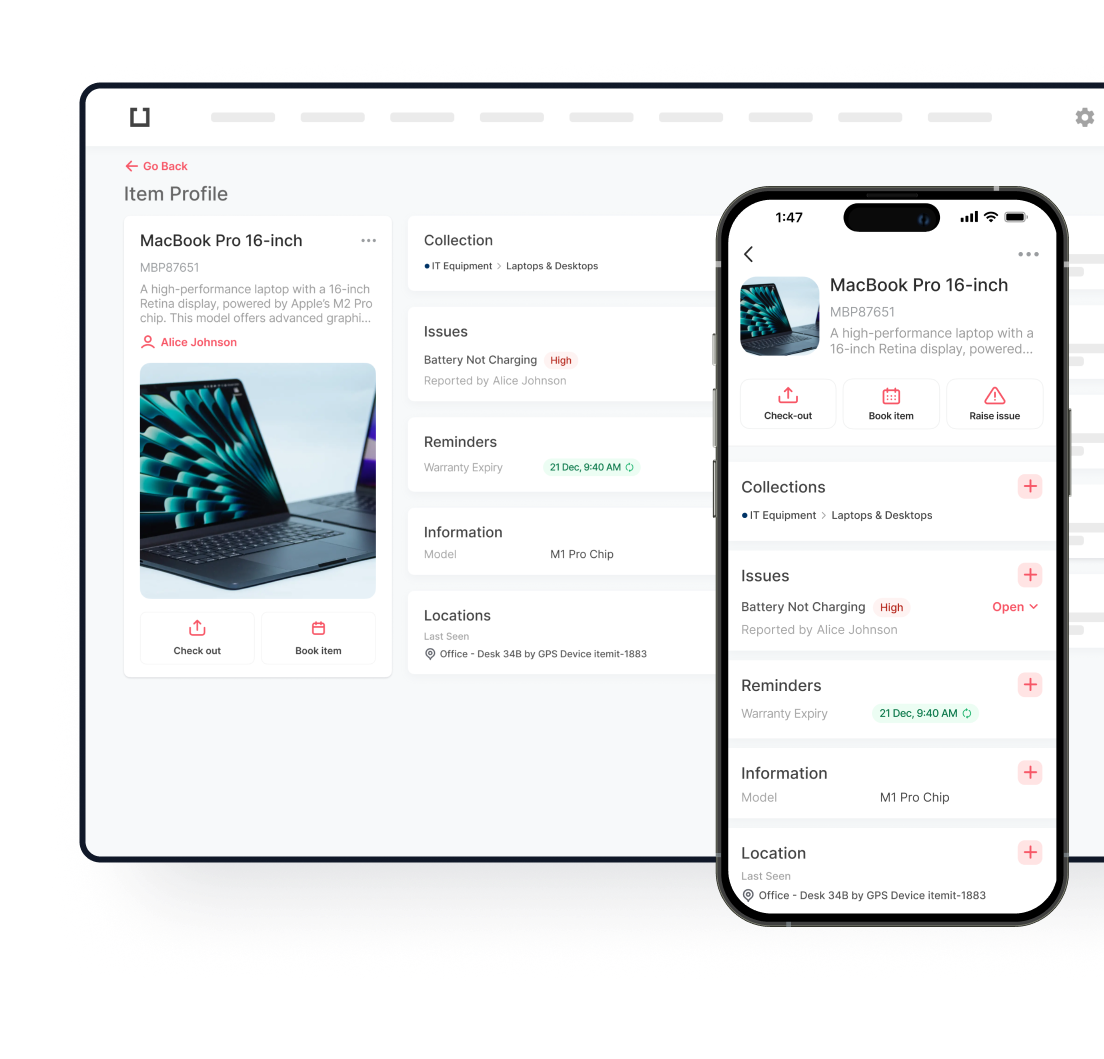

How itemit Asset Tracking Solution Supports VMI

itemit’s asset tracking platform provides the technological foundation needed for successful vendor-managed inventory implementation.

Our RFID and barcode scanning capabilities deliver accurate, up-to-the-minute inventory data that forms the backbone of effective VMI programs. Suppliers can access this information through secure portals, eliminating guesswork from replenishment decisions.

The platform automatically generates notifications when inventory approaches reorder points, ensuring your inventory vendor can respond promptly to replenishment needs without constant monitoring. Our built-in analytics tools help identify consumption patterns, allowing continuous refinement of your vendor-managed inventory parameters for maximum efficiency.

itemit connects with your existing ERP and your suppliers’ systems, creating the unified data environment necessary for VMI supply chain success. For businesses operating across multiple sites, our solution provides consolidated visibility while maintaining location-specific inventory parameters—perfect for complex vendor-managed inventory implementations.

The itemit difference for VMI programs includes:

- Real-time inventory tracking through advanced RFID technology and asset tags

- Customisable alerts and notifications for inventory thresholds

- Secure supplier access portals with role-based permissions

- Comprehensive analytics for consumption pattern identification

- Multi-location capabilities with centralised management

- Integration with existing business systems

Take Control of Your Inventory Management Today

Stop letting inventory management consume your valuable resources. With the right vendor-managed inventory partnerships and technology, your inventory can shift from a liability to a competitive edge that drives business growth.

The itemit asset tracking solution provides the visibility, automation, and analytics needed to make VMI work seamlessly for your business. Our platform bridges the gap between you and your suppliers, creating the foundation for successful inventory optimisation.

Why waste precious time and resources juggling inventory concerns? Contact itemit today and discover how our asset tracking solution powers successful vendor-managed inventory programs while freeing you to focus on what truly grows your business.

Try itemit

Choose a better way to track your assets. Start your free 14-day trial now!

Frequently Asked Questions

How does vendor-managed inventory differ from consignment inventory?

In vendor-managed inventory, ownership typically transfers to you upon delivery, and you pay for goods after receipt. With consignment, the supplier retains ownership until you use or sell the items. VMI focuses on who manages inventory decisions, while consignment addresses who owns the inventory.

What types of products work best with VMI?

Products with relatively stable demand, significant storage requirements, or critical operational importance typically yield the best vendor-managed inventory results. Components used in manufacturing, maintenance supplies, and regularly consumed retail goods are common candidates.

How much inventory reduction can we expect?

Most businesses implementing vendor-managed inventory experience 20-35% inventory reductions while maintaining or improving service levels. Results vary based on current inefficiencies and implementation quality.

Will VMI mean losing control of our inventory?

No. With proper implementation, you retain control of inventory parameters while delegating routine replenishment decisions. Your inventory vendor operates within boundaries you establish, and performance metrics ensure accountability.

How long does VMI implementation typically take?

For most businesses, moving from initial planning to a fully operational vendor-managed inventory takes 3-6 months for the first supplier relationship. Once the foundation is established, additional suppliers can be onboarded more quickly.

Keep Learning

itemit Blog

Tips, guides, industry best practices, and news.

Complete Guide to Asset Lifecycle Management and Its Benefits

Learn about asset lifecycle management and how it helps businesses optimize asset usage, reduce costs, and improve efficiency throughout the asset’s life.

The Key to Asset Reliability: Preventive Maintenance and Real-Time Tracking

Enhance asset reliability with preventive maintenance and real-time tracking. Reduce downtime, improve efficiency, and extend asset lifespan with smart strategies.

Optimising Asset Performance Management: Strategies for Maximum Efficiency

Explore practical strategies to optimise asset performance management, maximise efficiency, and enhance productivity with predictive and real-time monitoring tools.