What Is Equipment Management?

Equipment management starts with equipment tracking. It involves maintaining a detailed record of everything a business owns and how these assets are utilised. This process relies on attaching physical tags or barcodes to assets, enabling real-time tracking and location updates whenever a tag is scanned.

These tangible assets often include:

Appliances

Computers

HVAC equipment

IT equipment

Production equipment

Office furniture and safety devices

From a centralised online dashboard, users can monitor their equipment’s status, usage, and repair schedules. By investing in a high-quality equipment management system, businesses can save time, reduce costly errors, and enhance operational efficiency.

Top Tips for Better Equipment Management

Here are our 5 top tips for managing your equipment effectively:

Create an Inventory of Your Equipment

Your first step toward quality equipment management is building a comprehensive and accurate inventory of your assets. Count all your equipment, photograph it, and label it appropriately. Use a cloud-based system to store this data, ensuring it is accessible globally and safeguarded against disasters or data loss.

Having a robust inventory not only streamlines daily operations but also becomes invaluable during audits or insurance claims. Accurate records can expedite claim processes and establish the value of your assets.

Cloud systems not only keep your records safe but also allow real-time updates, ensuring your data remains accurate and actionable.

Track Your Equipment

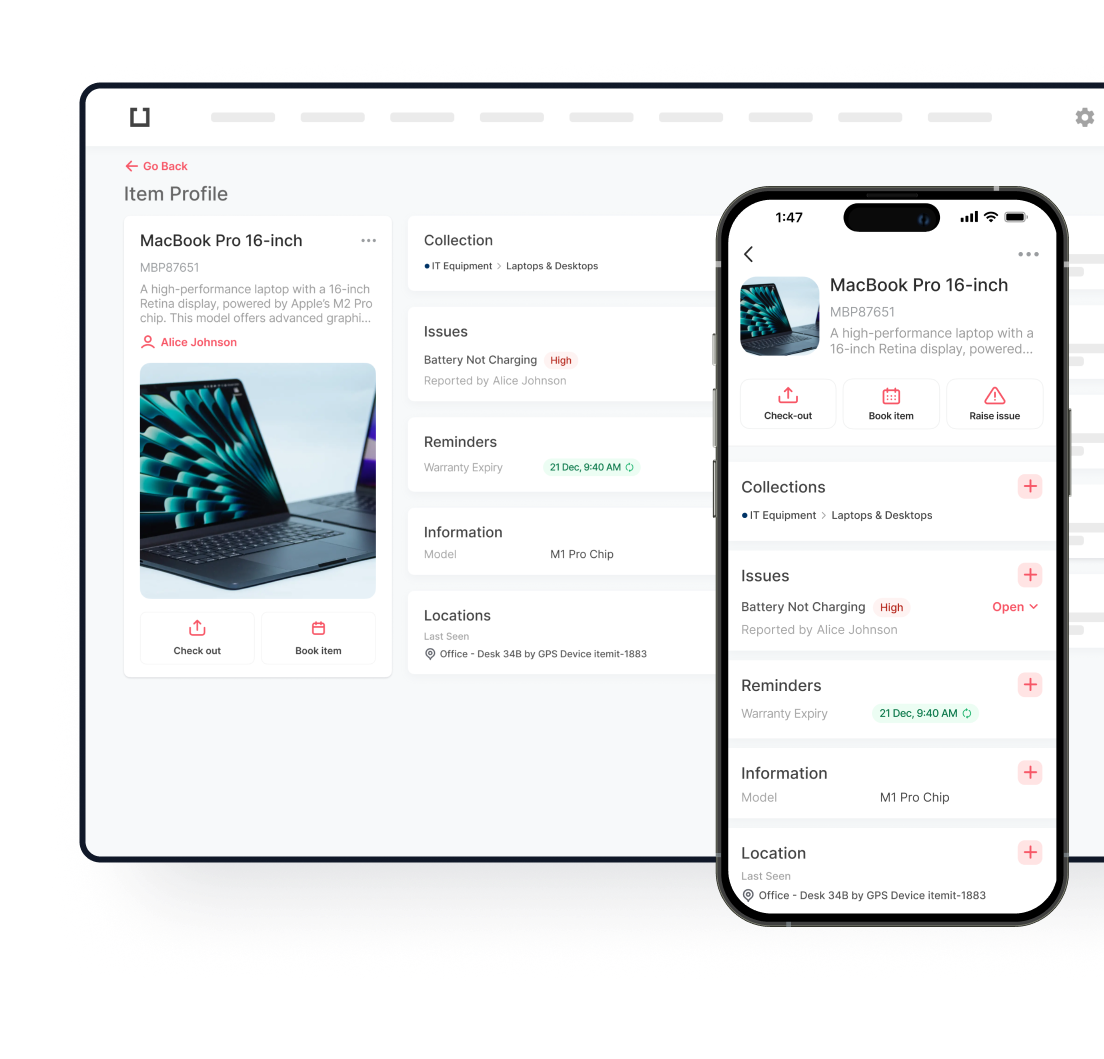

To manage equipment effectively, you need real-time insights into its location and status. Use tagging systems like barcodes, QR codes, or RFID tags to enhance asset identification. With tools like itemit’s software, you can tag, scan, and upload photographs of assets for easy recognition and centralised access.

With itemit’s real-time tracking, you can easily monitor asset locations and detect potential misplacements or unauthorised movements, reducing the risk of theft or loss.

Assign Assets to Users

Assigning assets to specific users promotes accountability and minimizes risks such as misuse or unauthorised access. Tools like itemit’s check-in and check-out function notify asset managers when equipment is moved, ensuring that only authorized personnel use and handle the equipment responsibly.

If employees consistently report problems with a particular tool, this insight can guide targeted training to prevent future mishandling.

Monitor Your Inventory

Modern asset management software gathers data that helps businesses understand their equipment’s utilisation, frequency of use, and maintenance needs. Leveraging these insights leads to better strategic planning and optimised purchases.

Data-driven monitoring not only saves costs but also ensures your business can anticipate future demands with confidence.

Predict and Schedule Maintenance

You can also use equipment management software to predict and schedule maintenance and repairs. Of course, breakdowns cannot be completely avoided and are mostly unexpected. You can, however, plan for the things you can control, such as equipment servicing, and apply data analytics to monitor equipment performance and predict repairs.

Predictive analytics leverages usage and maintenance data to forecast potential issues, enabling timely servicing and reducing costly downtimes. Small issues are addressed before they escalate, ensuring seamless business operations.

Bonus Tip: Stay Up-to-Date with Trends

Emerging technologies like IoT tracking and automation are revolutionizing equipment management. While itemit supports cutting-edge tracking systems, staying informed about trends ensures your business continually improves efficiency and decision-making.

IoT sensors can track asset conditions in real time, alerting teams to maintenance needs before disruptions occur.

itemit’s Equipment Management Software

Effective equipment management is the backbone of smooth business operations. Itemit’s software offers real-time asset tracking, automated notifications, and detailed reports, enabling businesses to reduce costs and increase productivity.

itemit’s Equipment Management Software

Effective equipment management is the backbone of smooth business operations. Itemit’s software offers real-time asset tracking, automated notifications, and detailed reports, enabling businesses to reduce costs and increase productivity.

Find out more about how our equipment management solution can take your business to the next level. Contact our friendly and helpful team today. You can reach them at team@itemit.com. Alternatively, you may want to consider signing up for our 14-day Free Trial to find out just how well itemit’s software can work for you.

Try itemit

Choose a better way to track

your assets.

Start your free 14-day trial now!

Keep Learning

itemit Blog

Tips, guides, industry best practices, and news.

Why Equipment Location Tracking Is Crucial To Your Business

Does asset tracking software ring a bell? If you want to improve your business’s productivity, learn more about asset tracking software in our Ultimate Guide!

Why Hospitals Need To Use Equipment Management Tools

Why exactly do hospitals everywhere need to use an equipment management system/tool? Read our latest post now to find out!

Save Money On Equipment Maintenance: 5 Tips

Saving money on equipment maintenance is never easy. Read this post now to discover how pre-emptive maintenance can help!