So, how are equipment tags going to take your equipment management to the next level? Quite simply by giving you many ways to speed up and improve your business’ existing operations.

Scan And Update Data In Your Asset Tracking System

This is helpful in all manner of equipment tracking operations. Whether it’s IT asset management operations or simply tools and equipment tracking, having the ability to scan and edit the asset in front of you removes a manual element.

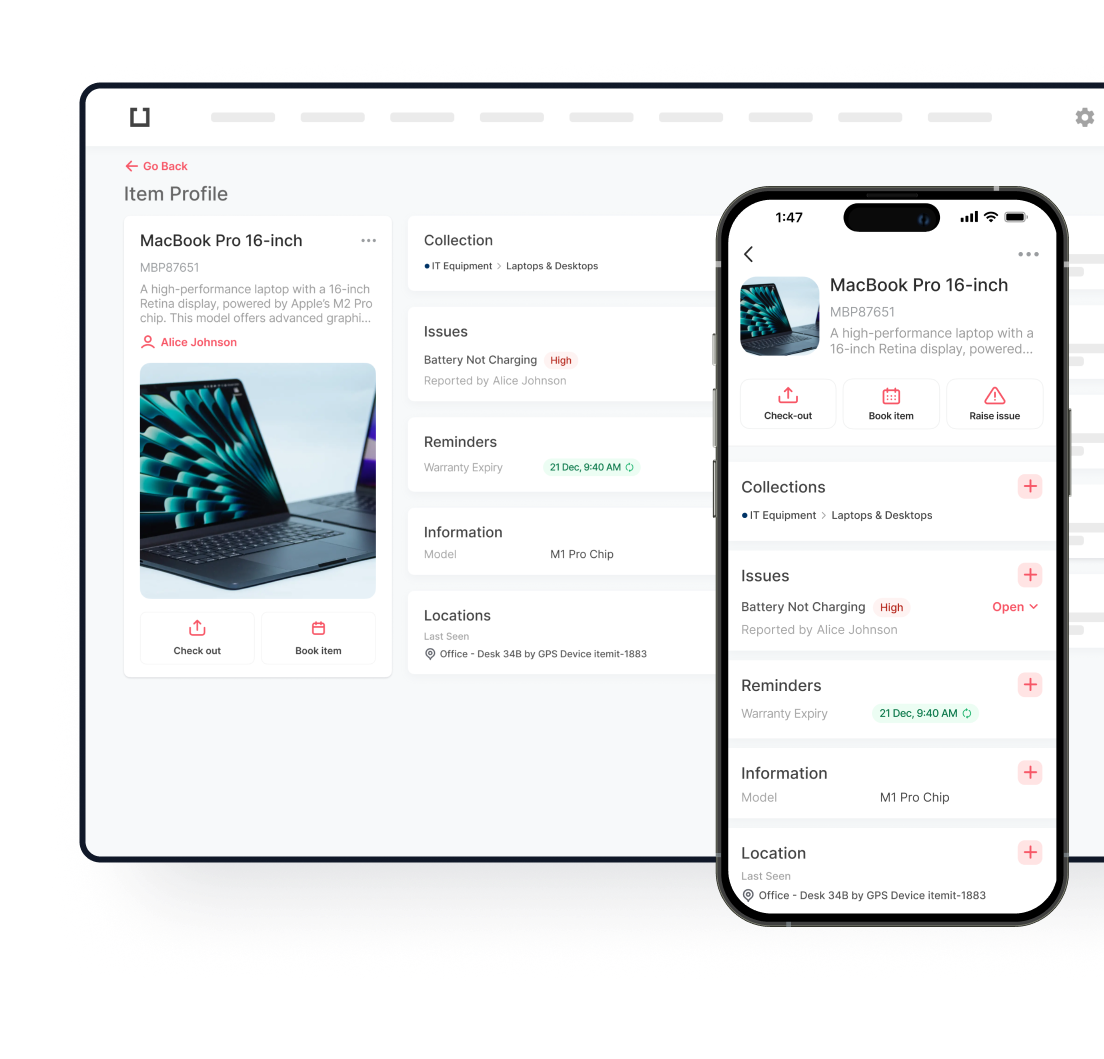

For example, if you notice one of your assets has an issue, the process of reporting this to your maintenance team is fast, simple, and effective. All you need to do is scan the asset’s tag and hit the “report issue” button.

This removes the need for spreadsheets entirely, as you no longer need to manually record asset issues or information and update your fixed asset register separately.

Speed Up And Improve Asset Audits

In practice, this is a speedy operation of hitting a button and then scanning all of your equipments’ tags. So, if you want to verify that assets that should still be on a shelf in your warehouse are there, you’ll be able to do this with ease.

Then, a similar function is the “quick add” feature, meaning you’ll be able to edit asset locations in bulk. In practice, if multiple assets are moving from one location to another, you’ll be able to use quick add to record this update.

Greater Transparency For Your Fixed Asset Management Operations

All of this feeds into your asset management software, automatically updating an exportable and customisable fixed asset register. This means that you’ll be able to use your on-site asset tracking operations in your fixed asset management procedures. Then, you’ll be able to export your fixed asset register and use it for insurance and accounting purposes.

Then, with itemit, you can speed up your operations further by using fixed RFID asset management. This allows you to update asset locations with no manual input whatsoever.

To find out more about how itemit’s asset tracking software will change your life, you’ll be able to contact the team at team@itemit.com. You can also fill in the form below to start your 14-day free trial.

Try itemit

Choose a better way to track

your assets.

Start your free 14-day trial now!

Keep Learning

itemit Blog

Tips, guides, industry best practices, and news.

Why RFID Tags Are Ideal For Tracking Fixed Assets

Why are RFID tags ideal for tracking fixed assets and what RFID tracking system should you use? Read this post now to find out!

Track High Value Assets With RFID Tags

Need to track high value assets but you’re unsure how? Use an RFID tracking tool that will make all the difference. Read this post to find out how!

Optimise Asset Tracking With RFID Tags

Wish to optimise your asset tracking? Use RFID tags to make the process smoother so you can control your assets easily. Read this post to find out more!