RFID, or Radio Frequency Identification, is a powerful technology. Using an RFID inventory system paves the way for total control and visibility over where your assets are within a room on a floor, an area in a manufacturing facility, or even a particular location on an open building site. It provides automation, which means that you no longer need to manually update any of your asset locations or even stock-check your assets regularly. This is where an RFID inventory system becomes invaluable, reducing time and effort for businesses.

Here, you will be able to find out more about how RFID inventory systems work and, therefore, how they will save your business time and money. The technology is relatively new, having been around for only about 20 years. However, it has already created a powerful level of automation one could only imagine a few years ago.

An Introduction To RFID Asset Tracking

Asset tracking has come a long way in the past decade. Many companies are still using the old ways of spreadsheet asset tracking to manage fixed assets, tools, equipment, and IT assets.

Asset tracking has come a long way in the past decade. Many companies are still using the old ways of spreadsheet asset tracking to manage fixed assets, tools, equipment, and IT assets. Spreadsheet asset tracking has always had gaps, but it was only recently that these gaps could be minimised through the use of smartphones, apps, and cloud-based software. Now, you can use RFID inventory management to log all of your assets. These assets can have unique profiles, meaning you can add unique data, such as issues and maintenance information, to your assets.

This is where RFID comes in. When you’re using an asset-tracking app, you can use asset tags to speed up asset discovery and audits. Most commonly, these tags will be barcodes and QR codes that are scannable with your phone’s camera. Then, when you scan one of these tags, the asset profile of the equipment it’s attached to will open on your app, and the last seen location will update. This integration highlights the benefits of a comprehensive RFID inventory system for asset management.

Overview of Types of Auto-ID Technology

Auto-ID technology refers to a group of technologies you can use to create digital twins of assets. In other words, you will be able to stick a barcode onto an asset and use this barcode to discover your asset within your asset tracking software.

As your assets are unique, Auto-ID technology must be unique, too, as each barcode, QR code or RFID tag will be used to find a specific asset within your system.

Here is a comparison chart of some of the Auto-ID technologies that are available:

RFID Asset Tags

RFID tags are effectively a supercharged version of barcodes. These super-tag labels are made up of an RFID chip adhered to an antenna to interact with RFID hardware.

Unlike barcodes, such methods of detection using radio frequencies do not require visual line-of-sight. Furthermore, an RFID inventory system is capable of reading thousands of RFID tags within a few seconds, providing a powerful new process to instantly detect the presence of large volumes of assets without the need to manually scan them one by one.

Active RFID Tags

Active RFID tags use batteries, meaning that they have a longer read range. This is because active RFID tags continuously send out a radio frequency for an RFID reader to detect, thus increasing the overall read range, much like a phone. The combination of RFID hardware, like the reader and tag, is critical when making a decision, as these are the two devices communicating with each other.

The combination of reader and tag is critical when it comes to a decision, as ultimately, these will be the two devices communicating with each other. You need to ensure that the read ranges of your RFID reader and your tags are larger than the gap between reader and asset while also taking into account that the highest read ranges will generally have the highest costs.

However, businesses need to be aware of the RFID inventory system cost when considering active tags, as larger batteries and more complex infrastructure can increase expenses. But bigger isn’t always better, as you can’t track small tools with large RFID tags, and bigger tags can be more expensive.

Active RFID tags, therefore, work within specific operations and the size of these tags can be a limiting factor in how well they work for you. Passive RFID tags have much more customizability when it comes to your operations and don’t require battery replacements.

Passive Long-Range RFID Tags

Passive RFID tags do not require batteries but have a lower read range. Whilst active tags communicate by sending out their own signal, greatly increasing the overall read range, passive tags only receive a signal, meaning that their read range is typically 3-5 metres using normal RFID readers but some up to 20 metres for long-range RFID readers.

The most common passive RFID tag for long-range detection uses Ultra High Frequency (UHF) tags, suitable for RFID systems for manufacturing environments. These tags are powered by the radio frequency emitted by the fixed RFID reader, ensuring efficient asset tracking. Passive tags are ideal for more confined environments like a shop floor, lab, or office, and they are often considered among the best RFID solutions for cost-effective asset management.

These EPC Gen2 tags do not require manual intervention after they’ve been stuck onto an asset and they can last about 20 years. They are also cheaper than active RFID tags with typically a much smaller form factor (some as small as a few specks of sand!).

Generally, this means that they’re more suitable for tracking smaller assets and more suitable when used in a more confined environment, such as a shop floor, lab, or office.

However, the reduced need to interact with these tags also means they’re more suitable for hazardous environments, so there is a lot to consider when it comes to choosing the best tags for your use case.

Both types of tags can be customised to your needs, and it’s important to note that certain tags interact with certain materials. Many passive RFID tags, for example, will not work on conductive materials such as metal, so this is another thing to consider in your search for RFID solutions.

For passive RFID tags there are three ways in which these passive tags can be read:

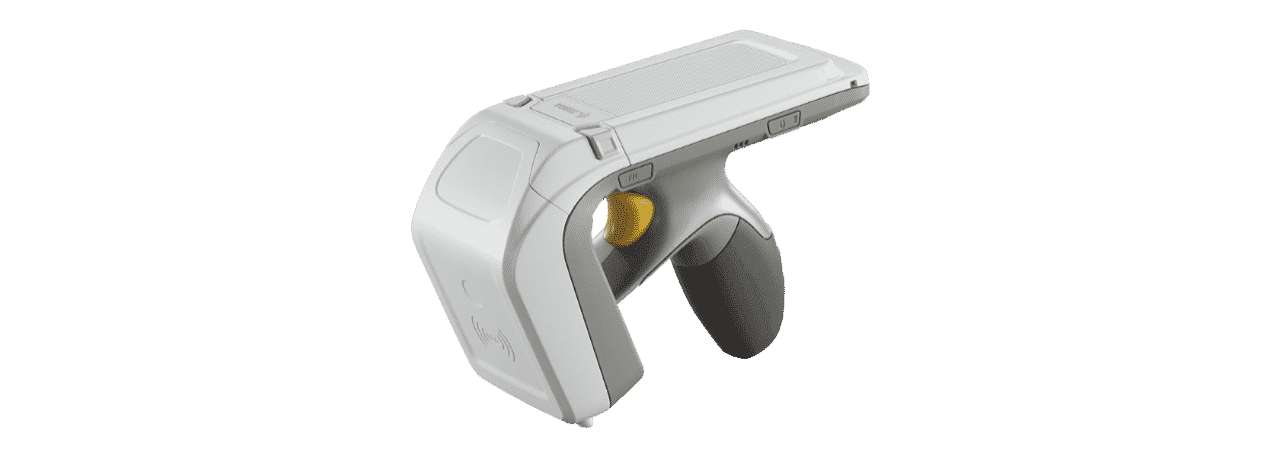

1. Using RFID handheld devices capable of detecting tags within 5 metres range

Setup:

An RFID handheld reader is required

Typical installation & Cost:

Up and running in minutes. Cost for one reader, you’re looking at around £1000

Capability:

a. Has mobility and can deduce location based on location tags or GPS of the smartphone

b. The cheapest option with the highest flexibility

c. Better than barcode because can read hundreds of assets within seconds

Challenges:

But has similar limitations in that you need a user to bring the device near the tagged object to scan them

Others:

Great for stock check and check-in/check-out processes

2. Using Fixed RFID readers typically connected with 1 or more antennas capable of detecting tagged assets within 10 metres area

Setup:

a fixed reader with 1 or more antennas, typically 4

Typical installation & Cost:

Up and running within 1 day given networking availability. Cost around £2500 per reader set

Capability:

a. Great for hands-free operation for any time tagged assets/equipment go past a particular zone location

b. One can also have multiple antennas multiplexed to reader

c. With itemit, you do not require any onsite middleware or servers

d. Readers only require power in, you can use wifi to simplify network deployment

Challenges:

a. Once fixed to the ceiling or wall, they can’t be removed that easily unlike handheld

b. For really high-density tagged assets, 100% readability may not be achievable but not impossible. Realistically you’re looking at 90% to 99% (whoever promises you 100% in all circumstances will be lying!)

c. Does not provide you with precise location within sub-metre, and only a zone location accuracy

d. Require large number of antennas and RFID readers to read a large area e.g. warehouse

3. Using Real-Time-Location System (RTLS) RFID Readers that is capable of providing an pinpoint x, y and z location within a metre

Setup:

Phased Array RTLS, only one reader (with in built antenna) required to cover a wide area

Typical installation & Cost:

Up to about £9,000 per reader, but the cost per metre will be much lower than 2 above. Installation will take say 2-3 days for each reader

Capability:

a. New cutting edge technology that’s available only in the past year that we believe will revolutionise large scale RFID tracking with the lowest cost of infrastructure

b. Provides true x, y, z location accuracy up to sub-metre accuracy

c. Great for open space (like open warehouse/factory) as it can be mounted high up in the ceiling that’s 20-30 metres high

d. Provide real-time movement of an asset sub-metre that can be mapped as a trail…

Challenges:

Not suitable for an area with low ceiling as this will increase cost per sq metre

How to choose which RFID Readers to Use

Location is everything when choosing the right RFID solution. You need to consider how large your location is and which type of RFID reader to use, whether a fixed RFID reader or a handheld option. Your operational zone and required read ranges are important factors. While handheld RFID readers offer flexibility, fixed RFID readers are often recommended for static environments, as they provide reliable coverage over a designated area.

In some cases, small businesses or startups may consider an RFID inventory system DIY approach to reduce initial costs. However, this might not always be the best long-term solution when compared to commercial-grade RFID systems.

This is also because the type of RFID reader will either track two dimensions or three. So, if you’re stacking boxes and wish to find where a box is on the Z access, you will need one type of reader, but if you’re tracking asset movements in and out of a room, the X and Y axes will be sufficient.

Handheld Reader-Based RFID

For smaller or more mobile operations, a handheld reader-based RFID system can be more effective. For example, a best RFID asset tracking setup might employ handheld readers to track high-value or mobile assets. This solution works well in environments where heavy infrastructure is not needed.

In this case, we would recommend handheld reader based RFID asset tracking systems. Handheld readers work by emitting a radio frequency when you pull a trigger. This frequency then detects the RFID tags.

This means that it is similar to barcode or QR code asset management systems, as you still need to scan your assets manually. However, there are still time-saving and accuracy-increasing benefits.

Your handheld RFID readers will connect to your asset tracking app via BlueTooth and work as a tag-scanning peripheral, similar to a barcode scanner.

However, one of the benefits is that tags do not need to be visible to be detected by any handheld RFID reader. This makes handheld RFID effective for high-value asset tracking as you can conceal tags under the frames of paintings, for example, to remove the need to add a visible tag to your assets.

This is also very useful when you’re auditing small tools. If you need to ensure your tags are in the location they should be, you can use the audit feature on your asset tracking software and simply pull the trigger. Your assets will be detected without the need to search for them and physically scan the tag.

Similar to this, if multiple assets are moving in bulk, you will be able to use a handheld RFID-based asset tracking system to reflect the change with the same method of pulling the trigger. RFID inventory management has never been easier!

The lack of line of sight allows you to detect smaller tools without spending any time physically finding them and also increases the capability for robust health and safety measures if your assets are hazardous.

Typical Fixed RFID Reader (Zone based)

These RFID readers work by using antennas. These antennas emit electromagnetic radio frequency fields that read a tag when it is within this field. The relevant antenna will then communicate with the reader which will, in turn, communicate with your asset tracking software. This also means that this system is binary. Either the tag is in the field, or it isn’t. This is how the location is deduced.

These fixed readers are typically supplied by Zebra, Impinj, Alien Technology and Caen to name a few suppliers.

A common example of how you can use this system is by affixing antennas on either side of a door. The reader can then detect the direction an asset is moving in as it will pass through antenna one and then antenna two or vice versa.

The electromagnetic field emitted diffuses outwards, creating something similar to a cone. If you mount your antenna to a ceiling this means that the higher an antenna is mounted, provided the floor is within its read range, the larger the surface area the tag will pass through. Therefore, if you can accommodate this, you can save money by increasing the read range of each antenna and can purchase fewer.

You can even add hundreds of antennas to a single RFID reader to create multiple read-zones, this is called multiplexing. Multiplexing allows you to track an asset’s movements around a room, as it will pass in and out of one RF zone into another, then another, and so on. However, in practice, multiplexing can cause a delay in the collection of location data as it can take some time to cycle between antennas. Hence, it is not suitable to track moving assets such as forklifts or pallets.

While the base cost of a reader package will be lower than a phased array system, these costs can add up depending on the number of antennas you need. This will eventually surpass the cost of a phased array system.

Long-Range Phased Array RFID Systems

These systems differ from traditional RFID setups by offering significantly higher read ranges, up to 20-30 meters. Such systems are highly effective in large warehouses or manufacturing environments where coverage is essential. By using advanced RFID technology, such as phased arrays, businesses can implement the best RFID asset tracking solutions with real-time tracking precision.

Commonly, these systems are mounted high up to cover a large space such as that of a warehouse, factories or a large area of a building with a high ceiling The difference in this technology means granular movement is also detectable, as an RF field will detect specifically where a tag is as opposed to whether or not it is in a zone.

Though the physics of RFID phased arrays is not new, it is only in recent years that this revolutionary RFID inventory system has been properly productised for commercial deployments. Imagine that every single asset on your site, whether pallets, forklifts, assets etc are tracked in real-time with sub-metre precision in 3D space – this was not possible before, and not possible with conventional RFID systems currently in the market.

Summary

In conclusion, selecting the right RFID inventory management system depends on your specific needs and operational zone. Whether you choose a passive or active tag system, ensure the solution aligns with your business objectives and budget. For large-scale operations, RFID systems for manufacturing offer unmatched scalability and precision, while smaller operations may benefit from handheld or phased array-based systems.

For example, if you need to track when assets move from one ward to another to track hospital assets without any manual input, a passive, non-phased array system will be sufficient. If you’re tracking where pallets are placed in a warehouse, it will not.

Once you’ve mapped out your building and your requirements and once you have a good idea of which system you need, you can then reduce costs by knowing the science behind RFID inventory management. For example, when you know how high up your building’s roof is, you can investigate the read range of antennas and choose a solution that requires the minimum number.

By carefully planning and considering factors such as RFID inventory system cost and your business's operational requirements, you can implement the best RFID system for long-term success.

itemit’s RFID Asset Tracking System

itemit is powered by RedBite Solutions, a company built on RFID expertise. RedBite has been working in the RFID sphere for over ten years and has the largest-scale RFID inventory system deployment active to date, deployed in over 60 countries worldwide.

This means that our team is qualified and happy to consult with you to help you find out the specifics of your requirements and recommend the best RFID deployment for you. The team can also create a bespoke solution for your needs if required.

Alternatively, you can take advantage of our off-the-shelf solution, itemit. itemit’s asset tracking software is a powerful cloud-based system that allows you to track specific asset information. Our RFID inventory system is unique as it allows you to combine RFID, GPS, QR code and barcode technologies to give you the highest level of accountability, transparency and control possible.

To find out more about itemit or to discuss a bespoke RFID solution, contact the team at team@itemit.com or call us on +44 (0)1223 421611. To check out the system and what it can do, you can also start a 14-day free trial by filling in the form below.