Start Using an RFID Tag Tracking System Today

Companies cannot afford to lose track of important assets anymore, and manual inventory counts are a waste of time. Businesses in the present competitive environment are realizing game-changing gains in operational efficiency, cost savings, and asset visibility after implementing RFID tag tracking systems.

Why Smart Businesses Are Making the Switch to RFID Asset Tracking Software

The numbers speak volumes about the impact of RFID asset tracking software. According to recent industry research, the adoption of RFID has led to a significant increase in inventory accuracy, from 65% to over 95%, across multiple sectors. Companies are seeing measurable returns, with RFID systems yielding a return on investment (ROI) of up to 200% for many businesses, particularly in manufacturing, logistics, and retail.

Consider these real-world transformations:

- Air Canada saves millions of dollars each year by tracking food carts used in airports around the world

- Club Car, a manufacturer of golf carts, used RFID tracking to reduce the assembly time of each vehicle from 88 minutes to 46 minutes.

- Adventist Health White Memorial in Los Angeles successfully reduced operating room turnaround times from 27 minutes to 24

The Technology That's Changing Asset Management

RFID tag tracking uses radio frequency identification technology to automatically identify and monitor physical assets in real-time. Unlike traditional barcode systems that require line-of-sight scanning, RFID tracking solutions can read multiple tags simultaneously from a distance, making asset management faster and more accurate.

The Three Core Components of Every RFID System

Every effective RFID asset tracking software solution consists of three essential elements:

- RFID Tags – Small devices containing a microchip and antenna that store unique asset information. These asset tags for equipment start at just $0.08 for passive versions, making them cost-effective for large-scale deployments across diverse operational environments.

- RFID Readers – Specialized devices that detect and collect data from tags using radio waves. Modern smartphones often include RFID reading capabilities, reducing equipment costs.

- Management Software – The brain of your RFID inventory tracking system that processes, stores, and presents asset data in actionable formats.

Active vs. Passive RFID Tags: Choosing the Right Solution

Active RFID Tags:

- Battery-powered with continuous signal transmission

- Read range up to 150 meters

- Cost between twenty-five and one hundred dollars

- Ideal for real-time location tracking and high-value assets

Passive RFID Tags:

- No internal power source, activated by reader energy

- Costs between 25 cents and five dollars each

- Perfect for inventory management and cost-conscious deployments

- Shorter read range but highly durable

Semi-Passive Tags:

- Battery-assisted for extended range while conserving power

- Balance between cost and performance

- Suitable for environmental monitoring applications

For a successful deployment, it is essential to have a solid understanding of the different types of asset tags.

Industry Applications That Drive Results

Asset tracking with RFID transforms operations across diverse industries:

Manufacturing Excellence

RFID efficiency is beneficial in the manufacturing field for tracking raw materials, work-in-progress, and finished goods. Manufacturers use RFID tags for asset tracking to monitor tool locations, schedule predictive maintenance, and optimize production workflows.

Healthcare Asset Management

Hospitals implement RFID asset tracking software to quickly locate critical medical equipment. Using RFID tags on devices enables staff to quickly locate needed equipment, improving treatment efficiency and reducing delays.

Retail Inventory Revolution

According to Zebra Technologies’ latest global research, 61% of retailers plan to be using RFID tracking by 2026. Retailers leverage RFID inventory tracking for automated stock monitoring, theft prevention, and seamless omnichannel experiences.

Logistics and Supply Chain

Transportation companies utilize RFID tracking solutions to monitor shipments, minimize losses, and enhance delivery accuracy. RFID-tagged shipping containers can be easily and quickly monitored throughout their route to ensure smooth port operations.

Your 5-Step RFID Implementation Roadmap

Successful RFID tag tracking system deployment requires strategic planning:

Step 1: Define Your Asset Tracking Objectives

Before selecting any RFID tracking solutions, clearly identify your business goals. Are you aiming to reduce inventory count time, improve asset utilization, or prevent theft? When you understand what the goal is, it’s much easier to determine the type of RFID tags and readers you need.

Step 2: Choose the Right RFID Equipment

Select RFID tags for asset tracking based on your specific requirements:

- Environmental conditions (temperature, moisture, chemicals)

- Read the range requirements

- Asset material composition (metal interference considerations)

- Budget constraints

Step 3: Select Compatible Software Solutions

Your RFID asset tracking software should integrate seamlessly with existing systems, such as ERP, WMS, or inventory management platforms. Look for solutions offering robust reporting capabilities and real-time analytics.

Step 4: Conduct Pilot Testing

Before full-scale implementation, it’s wise to conduct a pilot test. Create a controlled area to evaluate the RFID system’s performance. Start small to minimize risks and refine your approach before implementing it company-wide.

Step 5: Scale and Optimize

Once your pilot proves successful, gradually expand your RFID inventory tracking system. Monitor performance metrics and continuously optimize tag placement, reader positioning, and software configurations to ensure optimal performance.

Calculating Your RFID Investment

Understanding RFID asset tracking software pricing helps build realistic budgets:

Initial Investment Components:

- RFID Tags: Tags cost between 10p (passive) and £10 (active)

- Readers: Range between £500 (handheld) and £3,000 (fixed)

- Software: Fees range from £40 to £1,000 per month

Expected ROI Timeline:

RFID Tracking systems can provide fast and accurate inventories, which lead to not only labor savings but also improved asset utilization and reduced losses. Most businesses experience positive returns within 12 to 18 months of implementation.

Top Tips for Maximum Success

Implementing asset tracking with RFID successfully requires attention to these critical factors that can make or break your system’s performance. These RFID tracking top tips address the most common implementation challenges that organizations face when deploying advanced tracking solutions.

Environmental Considerations

Metal surfaces and liquids can significantly interfere with radio signals, reducing read accuracy by up to 70% in challenging environments. The most effective approach involves deploying on-metal RFID tags with special foam backing to isolate antennas from metallic surfaces. Strategic reader positioning at 45-degree angles optimizes signal reflection, while UHF tags operating at 860-960 MHz demonstrate superior performance around metal.

Wet environments demand tags with IP67 or higher ratings to maintain functionality. Ceramic and glass-based tags offer superior moisture resistance compared to standard plastic alternatives. Successful implementations begin with comprehensive site surveys to identify interference sources, testing read ranges in actual operating conditions rather than laboratory settings.

Building Seamless System Connections

Poor integration causes 40% of RFID implementation delays, making strategic planning essential. The foundation lies in mapping existing asset data fields to the RFID tag memory structure before deployment begins. Robust middleware solutions serve as the critical bridge translating RFID data into ERP-compatible formats, while automated data validation rules prevent corrupted information from propagating through connected systems.

Comprehensive end-to-end integration testing using actual asset data reveals potential issues before full deployment, ensuring a seamless integration. Simulating high-volume data scenarios tests system performance limits and identifies bottlenecks that could impact operations.

Staff Training and Change Management

Research indicates that 65% of RFID implementation failures are attributed to inadequate user training. Effective programs recognize that different roles require different approaches: management needs ROI metrics and strategic benefits training, operations staff require hands-on scanner operation and troubleshooting skills. At the same time, IT personnel must master system administration and technical support capabilities.

Creating simulation environments using actual equipment provides realistic training experiences that closely replicate real-world scenarios. Clear communication of tangible benefits helps overcome resistance. Explaining that “RFID will reduce your inventory time from 4 hours to 15 minutes” creates an immediate understanding of personal value.

Data Security Measures

With cyber threats increasing by 25% annually, robust security requires comprehensive protection strategies. Password-protected tags provide essential protection for sensitive assets worth over $10,000, while encrypted tag memory makes intercepted data useless to attackers. VPN connections for all RFID reader communications establish secure tunnels that protect data in transit.

Role-based permissions implement the principle of least privilege, ensuring employees only access necessary information. Regular security assessments and penetration testing identify vulnerabilities before attackers can exploit them, while ensuring GDPR, HIPAA, or industry-specific compliance requirements protect organizations from regulatory penalties.

Maximizing System Efficiency

Establishing baseline performance metrics during initial deployment creates standards for measuring system health. Monitoring read accuracy rates and investigating declining performance promptly prevents small issues from escalating into major problems. Designing systems with 30% additional capacity accommodates future growth without requiring complete infrastructure overhauls, while predictive maintenance schedules prevent unexpected failures that could disrupt operations.

Advanced RFID Capabilities

Modern RFID tag tracking systems offer sophisticated features that extend beyond simple location monitoring:

Real-Time Analytics

Advanced RFID asset tracking software provides predictive insights, usage patterns, and performance metrics that drive informed decision-making.

IoT Integration

The Internet of Things (IoT) is expected to become a significant trend in the development of RFID technology by 2025, enabling smarter and more connected asset management ecosystems.

Environmental Monitoring

Specialized RFID tags for asset tracking can monitor temperature, humidity, and other environmental conditions, crucial for sensitive equipment and compliance requirements.

Overcoming Common RFID Implementation Challenges

While RFID inventory tracking offers significant benefits, be prepared to address these common hurdles:

Budget Considerations

Implementing RFID systems can involve significant upfront costs. RFID tags, readers, and infrastructure require investment. However, the long-term benefits typically justify the initial expense.

Technical Complexity

Tag Interference and Read Range: RFID tags can experience interference from materials such as metal or liquids, which can impact the readability of tags. Work with experienced providers to optimize system performance.

Change Management

Resistance to change or a lack of training can hinder the successful adoption and utilization of RFID systems. Invest in comprehensive training programs and clear communication about benefits.

The Future of RFID Asset Tracking

RFID tracking solutions continue evolving with emerging technologies:

Artificial Intelligence Integration

AI-powered analytics enhance RFID asset tracking software capabilities, providing predictive maintenance insights and supporting automated decision-making.

Enhanced Security Features

Manufacturers of RFID tags must adapt to this trend by introducing labeling solutions that meet environmental requirements, including enhanced data encryption and robust privacy protection.

Smaller, More Powerful Tags

Technological advances are producing smaller, more durable RFID tags for asset tracking with extended battery life and improved read ranges.

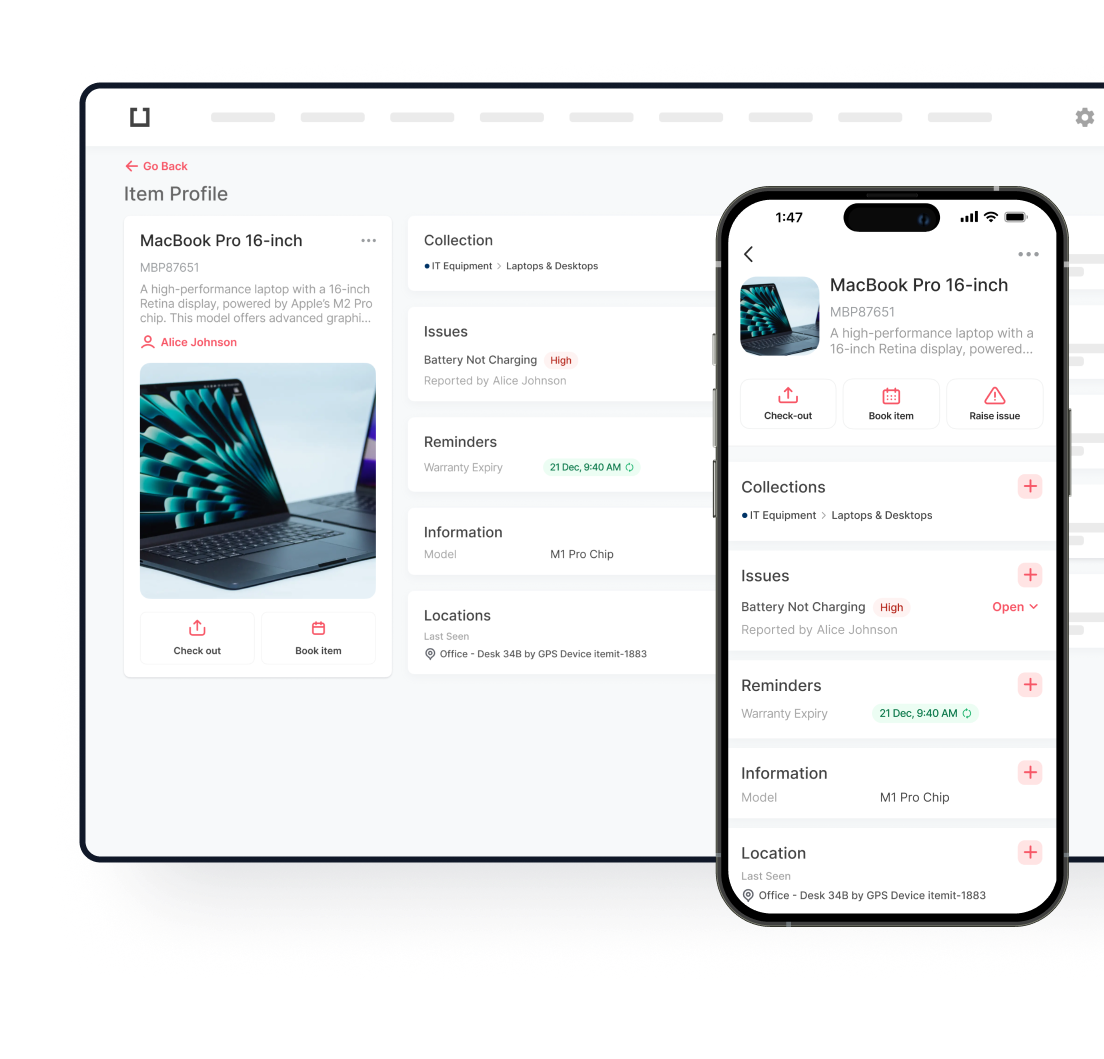

Why itemit Leads RFID Innovation

When selecting RFID asset tracking software, partner with proven industry leaders who understand your unique challenges, itemit combines cutting-edge RFID tracking solutions with user-friendly interfaces and comprehensive support services.

Our platform offers:

- Seamless integration with existing business systems

- Scalable solutions for businesses of all sizes

- Advanced reporting and analytics capabilities

- Expert implementation support and ongoing training

- Flexible deployment options for diverse industries

Start Your RFID Journey Today

The question isn’t whether RFID tag tracking systems will benefit your business—it’s how quickly you can implement them to gain competitive advantages. With the Radio Frequency Identification Technology Market projected to reach USD 47.63 billion by 2030, rising at a CAGR of 15.80%, early adopters are positioning themselves for sustained success.

Don’t let manual processes and asset uncertainty hold your business back. Contact itemit today to discover how our RFID asset tracking software can transform your operations, reduce costs, and improve efficiency.

Ready to revolutionize your asset management? Explore our comprehensive RFID tracking solutions and join thousands of businesses already experiencing the benefits of intelligent asset tracking.

Try itemit

Choose a better way to track

your assets.

Start your free 14-day trial now!

Keep Learning

itemit Blog

Tips, guides, industry best practices, and news.

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.