"A simple, inexpensive solution"

How itemit is helping with equipment tracking

When the future is being created, it’s more important than ever to keep track of the tools and equipment that are helping to build it. This is well known by Professor Simone Hochgreb of Reacting Flows.

Reacting Flows is a research group in the University of Cambridge’s Engineering Department. Their goal is to better understand the physics of reactions during energy conversion. With this understanding they plan on taking the applications everywhere, ultimately creating a more efficient energy conversion process, and less emissions with more economical energy convertors.

Of course, this requires a lot of equipment both large and small. Not only this, but with a consistent rotation of students, this equipment is a lot more difficult to track and inventory. It is also imperative that equipment isn’t mixed up or misused. To help with these difficulties and potential problems, Professor Hochgreb reached out to itemit. Find out more about the problems, and the solutions, below.

About Professor Hochgreb

Simone Hochgreb is a Professor of Engineering currently working in Cambridge University. In the past, however, she has worked all over the place, including in São Paulo and Princeton.

Her research has been related to combustion engine performance, chemical engineering, and auto-combustion. This knowledge has developed into her current research projects, where not only does she teach a large amount of students, but also investigates problems facing humanity today.

Cambridge University’s mission statement involves serving the needs of society, whether it be artistically or in terms of science or engineering. This environment has both motivated and cultivated incredible research, such as Professor Hochgreb's.

Hochgreb Lab research

The research Professor Hochgreb is undertaking requires so many different assets and unique pieces of equipment in order to work. As she is trying to replicate energy transfer and use what her team discovers in a real world environment, realistic and repeatable conditions are greatly needed.

For conditions to be repeatable and realistic, the correct equipment is imperative. Not only this, but the risk of a loss is a big one to take. A lost piece of equipment not only sets back wallets, but it could also affect the legitimacy of the tests. A loss could mean the repeatability is damaged or destroyed, meaning hours of research could be lost. Careful planning and hard work help Professor Hochgreb and her team prevail.

The team uses a wide range of equipment. From larger assets such as lasers, scopes, and electronic boxes needing constant maintenance, to medium equipment such as detectors, to smaller assets such as optics or optoelectronics. Keeping these assets categorised and carefully looking after them is of the utmost importance.

Professor Hochgreb is working on something massively important. She is researching towards the ability to create more efficient energy transfer. It doesn’t need to be said how much this is needed in our current situation. As Professor Hochgreb creates breakthroughs, she moves us all closer to a more energy efficient world where less energy and pollution is lost during combustion, thus making energy sources cheaper and more productive.

The Problems

As there is a lot that has to go right, there is also a lot that can go wrong. There’s a lot of pressure on keeping equipment maintained and inventoried so that it’s less likely to get lost, it continues to work, and it isn’t mixed up with similar assets.

These problems increase financial and time pressures, as lost assets need to be replaced and missing assets need to be found. In a University Engineering atmosphere, time and money are crucial, and wasting them on avoidable situations was becoming a frustration for Professor Hochgreb. There's also a possibility of using expensive equipment that needs to be maintained and monitored. It can be stressful to think about the status of equipment like this and there are a range of ways to increase peace of mind, but some are more effective than others.

A rotation of students also creates potential problems, worsening the already problematic time and financial constraints. A rotation creates the possibility of more lost or misplaced assets. There’s more time spent on inventorying and making sure each rotation has the correct assets at the correct times and on making sure things don’t go missing.

New students must also quickly ease into their University careers and start learning. This means that knowing the assets that are available to them needs to happen quickly, as does learning how to use these assets

The nature of having unique, but similar looking assets also created issues with inventory. With two pieces of equipment that look almost identical, but that do very, very, very different things, it’s crucial to make sure you’re using the right one at the right time. Before the ability to simply scan and read which asset it is, there was more of a need to physically inspect and find a certainty that the asset being used is the correct one. This is time that doesn’t need to be wasted, and a risk of human error is still present with physical inspection.

Without equipment tracking, all reports and information became very unweildy, very quickly.

The Solution: Equipment tracking

Professor Hochgreb stumbled across itemit by chance. She saw an air conditioning unit at the University of Cambridge being tagged by a colleague and, following a swift conversation with her colleague, contacted us here at itemit to see if she could use the tool to tag and inventory all of her lab assets too and of course, we were delighted to help!

Before she found out about us, Professor Hochgreb had been looking for a low cost solution to track her lab assets, but found that elsewhere it was always either inadequate or too top-heavy.

Professor Hochgreb uses itemit with two user licenses, inventorying and tracking her equipment with a co-worker. She tracks her assets in order to link them to user manuals, to keep track of necessary maintenance, to know where assets have been left, and in order to know where assets are when groups of students move from room to room.

Also, Professor Hochgreb is adding her students to itemit with its new features so that they can see where assets are and read the manuals. This means that they can quickly find assets and quickly learn how to use them, ensuring no time is wasted on research.

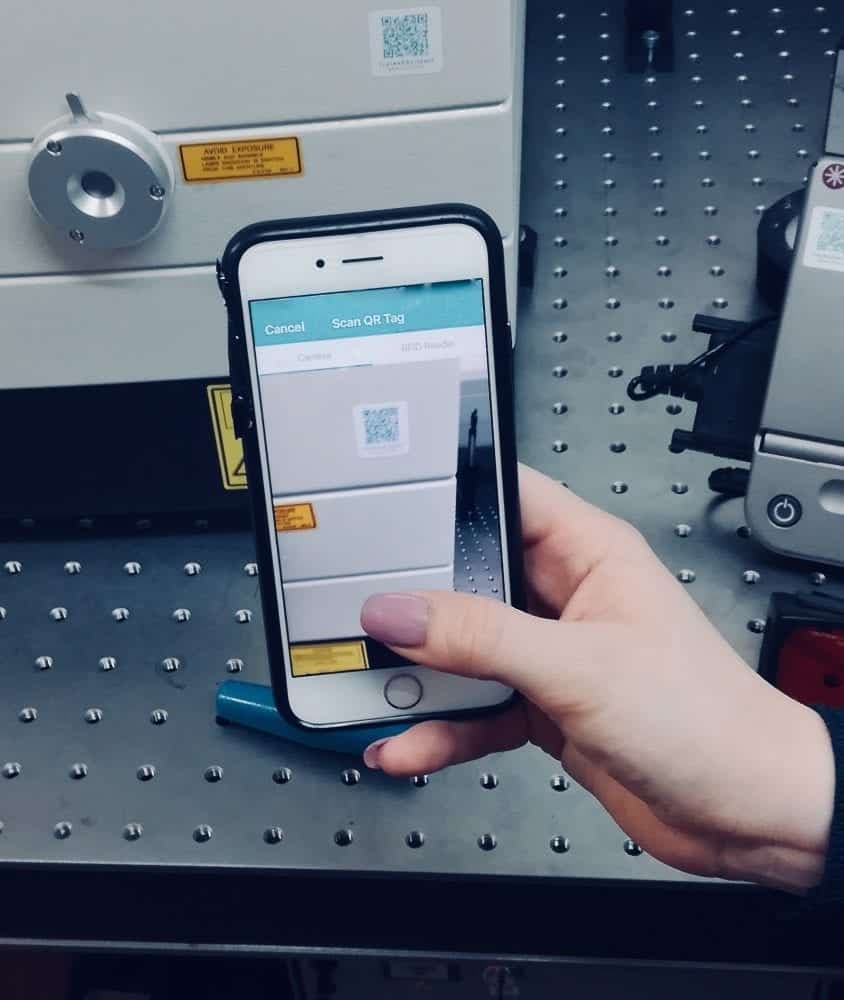

Unique QR tags suited Professor Hochgreb's purposes better, and so she has bought 200 QR asset tags. RFID tracking is a possibility with itemit as it can help find things that cannot be seen, but not always necessary depending on a user’s individual purpose. As the QR tag system has worked, Professor Hochgreb has been using itemit for over a year (since September 2017) and has renewed her membership for another one.

Less things go missing and there are less replacements needed, and so less money is spent. Not only this, but as it’s possible to look through the inventory with ease, now all it takes is a quick check on the phone to see if an asset is needed, or if it is already owned. No more duplicates!

Recommendation

When we asked Professor Hochgreb for a Testimonial, this is what she said:

"We are using itemit to track laboratory equipment. We were looking for a simple, inexpensive solution when we came across itemit. The itemit team have been really helpful in getting us off the gates. So far we have logged about a hundred items, along with their locations, links to their manuals, and how to use them. Now all our researchers looking for something just need to consult the inventory to know whether we have something and where it is!"

Her colleagues also reported that they were very happy customers, and that the app had been incredibly helpful for students both old and new.

Need an Equipment Tracking Solution?

Begin a trial of itemit Enterprise and you'll receive free QR asset tags!

No strings attached! You choose whether to continue using itemit after your 14-day trial.

or, download the itemit app to get started