Consider a firm an orchestra, with an asset monitoring system conducting the delicate balance between supply and demand. Inventory planning involves strategic decisions regarding what to stock, how much, and when. This complex process underpins operational efficiency, customer happiness, and financial health, not just stockroom maintenance.

Consider how a miscalculated inventory decision affects an organisation: stockouts cost firms more than sales. Frustrated customers switch to competitors, and emergency replenishment orders consume resources due to faster shipment and high supplier charges. The domino effect of stockouts can damage brand relationships and market position.

However, excess inventory in warehouses traps enterprises in a distinct financial quicksand. Unsold goods freeze capital, warehouse space fills up at premium rates, and products deteriorate. Inventory bloat restricts storage capacity and costs money in holding expenses, insurance, and unsold goods write-offs.

Inventory planning is essential in today’s fast-paced economy. This financial lever affects cash flow, operational costs, and the bottom line.

What is Inventory Planning?

A key component of operational excellence in the ever-changing business environment of today is efficient inventory planning. Modern inventory planning goes well beyond basic stockroom management and includes complex techniques that maximise resource allocation, forecast market demands, and balance supply networks. Businesses that have a strong inventory management strategy in place are frequently in a better position to handle changes in the market and have good profit margins.

Inventory Planning as a Critical Business Strategy

Think about how an organised inventory planning and management system improves corporate operations by reducing carrying costs and guaranteeing that product availability satisfies client demands. Organisations must use a variety of inventory planning techniques, such as statistical forecasting and real-time tracking systems, to maintain this delicate balance. These systems’ intricacy demonstrates why companies are beginning to see inventory management and planning as a strategic task rather than just a tactical one.

Organisations must take into consideration a number of factors while creating an inventory in their business plan, including storage capacity limitations, supplier lead times, and seasonal variations in demand. As organisations grow and need more advanced methods to be efficient, a thorough inventory control plan becomes even more important. Advanced inventory planning systems that use artificial intelligence and predictive analytics to maximise stock levels have emerged as a result of this evolution.

Planning and inventory management are related in ways that go beyond simple stock control. Cash flow, consumer happiness, and market competitiveness are all directly impacted. Emerging market prospects, shifting customer habits, and global supply chain disruptions must all be taken into consideration in modern inventory management planning. A thorough grasp of both modern market dynamics and conventional inventory planning methods is necessary for success in this field.

The High-Stakes Balancing Act of Inventory Planning

Examining how inadequate inventory planning affects profitability raises the stakes. Both short-term revenue losses and, more importantly, long-term customer attrition can be caused by stockouts. On the other hand, too much inventory threatens obsolescence, raises storage expenses, and ties up money. Businesses can steer clear of these problems and maintain ideal stock levels that foster expansion and profitability by using strategic inventory planning.

Essentially, inventory planning has become a crucial component of corporate strategy that requires consideration at all levels of the organisation. What started out as a simple tracking system has evolved into a complicated operation that necessitates constant monitoring, modification, and optimisation due to the growing complexity of global marketplaces.

Common Challenges in Inventory Planning

Three interrelated issues that can significantly affect company performance are frequently the manifestation of the complexity of inventory planning. Comprehending these obstacles aids businesses in creating more efficient inventory management to safeguard their profits.

The Perils of Overstocking: Frozen Capital and Missed Opportunities

Overstocking is the first significant obstacle that leads to a series of financial issues. Warehouses are overstocked, and valuable working capital is turned into stagnant assets when inventory planning systems are unable to foresee demand. In addition to putting a burden on storage capacity, this misallocation of resources due to inadequate inventory planning results in significant carrying expenses, such as opportunity costs, depreciation, and insurance. The warehouses full of the previous season’s designs represent frozen capital that could have financed new opportunities or innovations. Take the example of a fashion company whose inventory management plan failed to take into consideration the quickly evolving trends.

A crucial economic lesson is revealed by Forever 21: rigid inventory control can lead to the demise of even prosperous retail behemoths. The corporation was stuck with enormous unsold stockpiles as a result of its inability to predict quickly shifting customer trends. Large markdowns gradually reduced profit margins, which led to the company’s insolvency. This glaring example shows that inventory planning is a strategic function that determines a company’s economic future in the fast-paced fashion retail industry, not just a logistical task.

The Devastating Impact of Stockouts on Business Performance

When inventory planning and management systems are unable to predict client demand, stockouts occur, which is equally disastrous. These expensive situations can be difficult to avoid even with advanced inventory planning techniques, particularly in sectors with erratic demand trends. The effects of buyers seeing bare shelves go well beyond the immediate loss of sales. Since contemporary consumers rarely grant second chances in today’s cutthroat market, their dissatisfaction frequently results in long-term brand damage and diminished loyalty.

Adapting to Market Volatility: The Challenge of Dynamic Inventory Management

When confronted with sudden external events, seasonal variations, or quick changes in the market, traditional planning and inventory management techniques can occasionally break down. To account for these factors, organisations must constantly improve their inventory control strategy, but many have difficulty striking the correct balance. Businesses where customer tastes shift frequently face this difficulty, which makes precise inventory planning more difficult.

In order to successfully adopt an inventory planning system, firms must tackle these issues from all angles. Businesses need to include supply chain insights, consumer behaviour analytics, and real-time market data with their inventories in their business plans. Predictive analytics and adaptive methods that can foresee and react to market changes before they affect operations are now part of modern inventory management planning, which has progressed beyond basic stock tracking.

Businesses’ ability to coordinate their inventory planning activities across many organisational units is often critical to their success in overcoming these obstacles. Coordinated inventory planning across marketing campaigns, sales projections, and supply chain operations increases the likelihood that organisations will maintain ideal stock levels while reducing overages and stockouts.

Inventory Planning Methods: Choosing the Right Approach

- The Just-in-Time (JIT) method, which aligns material deliveries with production schedules, transforms conventional inventory planning and control. Organisations using JIT inventory planning work closely with suppliers to ensure that materials are delivered exactly when needed, as opposed to keeping significant safety reserves. To reduce storage costs and preserve production flow, a computer manufacturer, for instance, can make arrangements for components to arrive at the assembly line precisely as needed. This approach works best in supply chain systems that are stable, since it requires excellent coordination and trustworthy supplier relationships.

- Inventory planning and management are made more mathematically precise by Economic Order Quantity (EOQ). By weighing the costs of ordering and storage, this algorithm determines the ideal order quantity. To find the most economic order size, a strong inventory planning system that uses EOQ takes into account factors including demand rates, holding costs, and order processing charges. While maintaining appropriate stock levels, this scientific method assists businesses in reducing overall inventory expenditures.

- By classifying goods according to their worth and relevance, ABC Analysis improves the creation of inventory control plans. This approach acknowledges that not every inventory item merits the same level of planning and inventory management attention. Organisations can more efficiently deploy their management resources by dividing products into three tiers: “A” items require strict supervision, “B” items require moderate oversight, and “C” things require basic monitoring.

- Perhaps the most dynamic component of contemporary inventory planning techniques is demand forecasting. Companies can now anticipate future needs with previously unheard-of accuracy, thanks to advanced analytics and machine learning. These forecasting skills must be incorporated into a business plan’s inventory in order to predict future demand by examining past data, seasonal trends, and market trends. By taking a proactive stance, companies can minimise stockouts and surplus inventory while maintaining ideal stock levels.

- Strategies for inventory management planning gain a vital element of security from Safety Stock Planning. In order to protect against supply chain interruptions or unforeseen demand spikes, this methodology assists enterprises in determining the proper buffer stock levels. By combining safety stock computations with real-time market data, contemporary inventory planning techniques allow buffer levels to be dynamically adjusted in response to changing circumstances.

The secret to success is choosing and integrating various approaches according to certain business requirements. Businesses may use hybrid strategies, keeping safety stocks for essential components while utilising JIT for high-volume commodities. Businesses may enhance their operations while remaining resilient to market uncertainty thanks to this adaptable approach to inventory planning.

Implementing an Effective Inventory Control Plan

Determining Optimal Stock Levels: The Scientific Approach

Precision in Reorder Points: Ensuring Continuous Supply

Inventory Turnover: A Critical Performance Indicator

The Role of Automation and Real-Time Data

Continuous Improvement: The Key to Long-Term Success

The Role of Asset Tracking in Inventory Planning and Management

RFID Technology: Precision at the Forefront of Inventory Tracking

IoT Sensors: Intelligent Environmental Monitoring for Inventory Preservation

Real-Time Tracking: Dynamic Inventory Management in Action

Cloud-Based Solutions: Unifying Inventory Management Across Enterprises

Artificial Intelligence: Predictive Insights in Inventory Planning

The Integrated Ecosystem: Connecting Internal Tracking with External Supply Chains

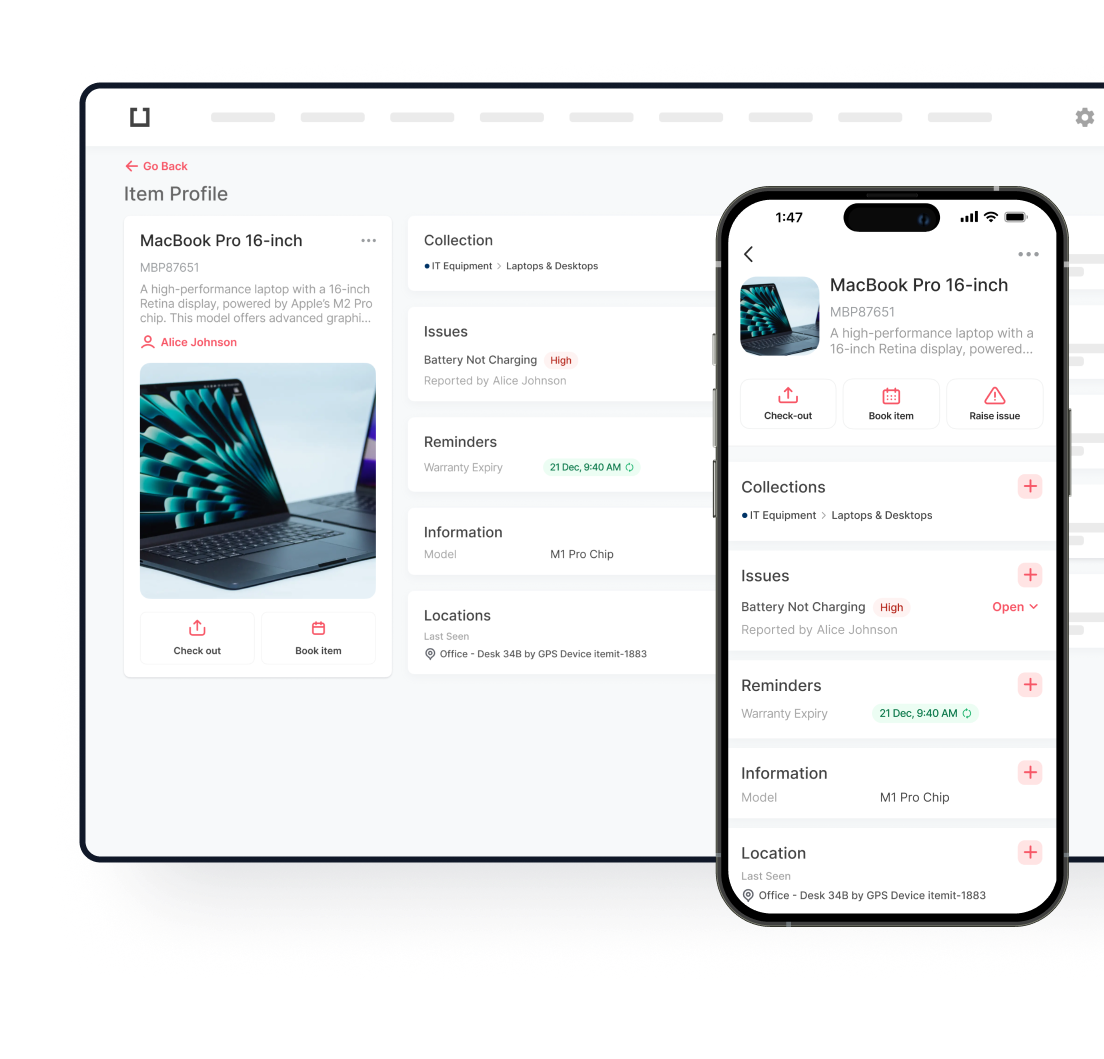

Try itemit

Choose a better way to track your assets. Start your free 14-day trial now!

Latest posts

itemit Blog

Tips, guides, industry best practices, and news.

How to Optimise Product Inventory Management

Learn how to optimize product inventory management with effective strategies, a product inventory management system, and best practices for efficiency.

How to Keep Your Asset Record Accurate and Up-to-Date

An accurate asset record is crucial for businesses aiming to optimise their operations, minimise costs, and enhance compliance. With itemit’s intuitive fixed asset management software, you can streamline your asset tracking process, ensuring that your records are always current and reliable.

What Is IT Asset Disposition (ITAD)?

Learn about IT Asset Disposition (ITAD), its benefits, and best practices for secure asset tracking. Optimize ITAD strategies for efficiency and compliance. Read more!